CTCI Helps Taiwan to Build a Highly Efficient Transportation Network

Power Supply System Project for Taichung Rapid Transit Systems

- Market:Transportation/Mass Rapid Transit (MRT)

- Client:System-wide E&M Project Office, Department of Rapid Transit Systems, Taipei City Government

- Prime Contractor: CTCI, ALSTOM, KHI Consortium

- Substantial Completion Date: 2018

- Location:Taichung City, Taiwan

- Scope of Work:E + P + C + C

- Total Length of Route:16.71 km

CTCI was awarded the power supply system contract for Taichung Rapid Transit Systems in April 2011. The approximately 16.71 km route has 16 elevated stations, 2 ground stations, 2 bulk supply substations (BSS), and 1 five-level depot. The route links the Taichung THSR Station and the Taichung City center, which connects the Beitun, North, Xitun, Nantun, South, and Wuri Districts in Taichung City, providing an efficient and fast means of transportation for riders while effectively relieving traffic jams.

Why CTCI?

Highly Professional Techniques with Plenty of Experience in Taiwan

CTCI’s involvement with the E&M-system projects of Taiwan’s MRT began in 1989 with the Muzha Line of the Taipei MRT. The company then successfully completed power supply system projects on the Nangang-Banqiao and Tucheng lines of the Taipei MRT. Having gained experience with these projects, a CTCI-Alstom Transport S.A. Consortium won the E&M systems contract for the Taipei MRT’s XinZhuang and Luzhou lines in 2003. This was followed, in 2007, by a similar project for the Taipei MRT’s Xinyi and Songshan lines, which were contracted to a consortium consisting of CTCI, Kawasaki Heavy Industries, Ltd., and Marubeni Corporation. The ongoing project for E&M and automated fare collection (AFC) systems for Taichung’s Wuri-Wenxin-Beitun Line ensures CTCI’s leading position in E&M systems for Taiwan’s MRT network. The issuance of contracts for the Taichung MRT system differs from other MRT contracts in Taiwan. The E&M contract is issued prior to the civil contract, which means that E&M contractors have to provide the parameters and functionalities so that clients can develop and issue the civil contracts. As the power supply contractor of the Taichung MRT system, CTCI faces many tough challenges. For instance, there may be delays in awarding the civil contracts, work sites may be confined, and clients may have high expectations on matters such as target power energization. Prioritizing on-site safety issues, CTCI consistently does its best to overcome various difficulties to achieve the scheduled milestones and win clients' commendations.

Reliable Realized

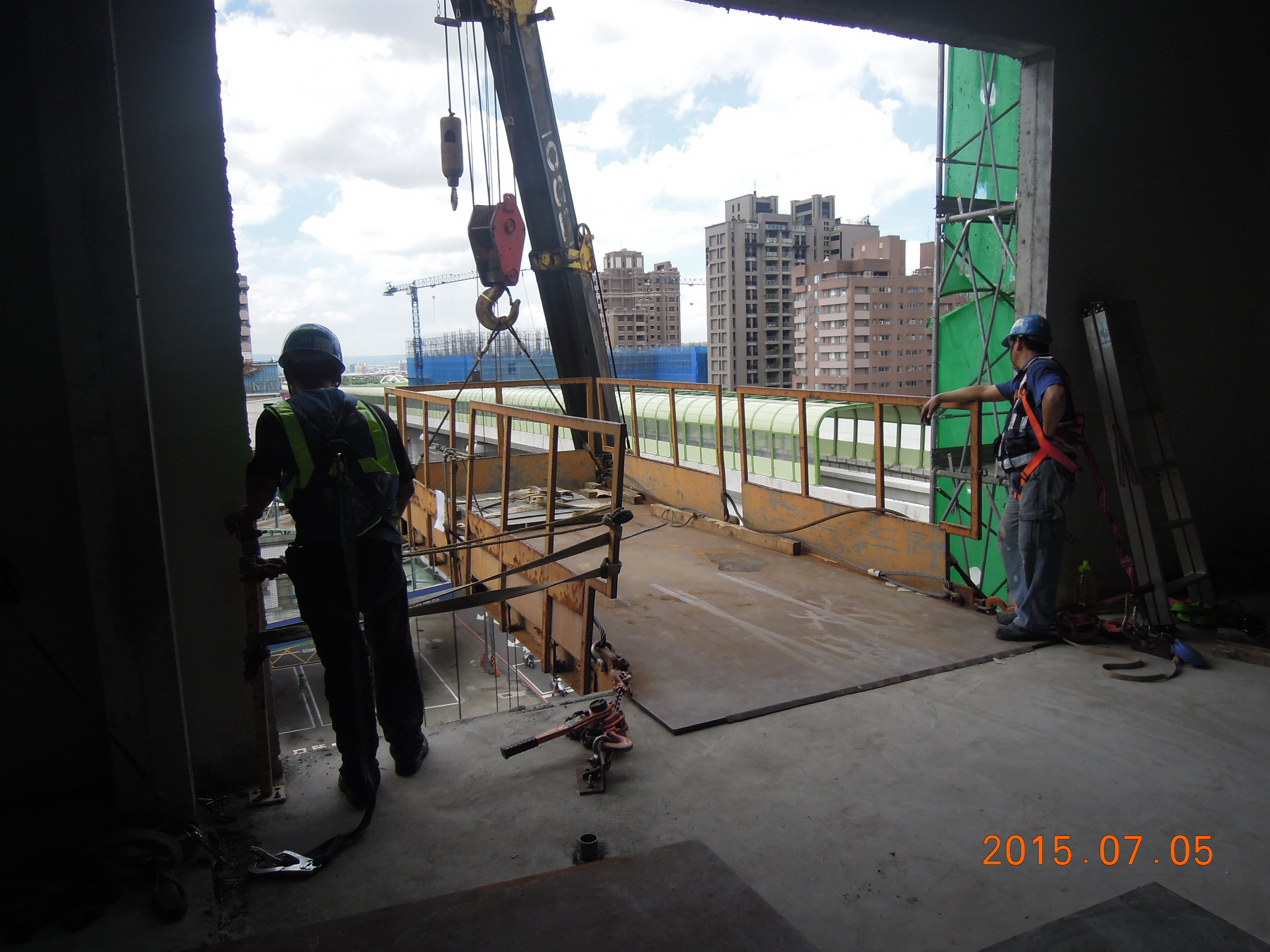

A Special Method for Lifting in Confined Elevated Sites

For the delivery of power supply equipment to the S/S (electrical power substations) at Taichung MRT’s elevated stations, the work opening was set on either the wall of the S/S next to the road with existing residential buildings, on private land without an unloading platform, or the equipment room of the adjacent JV building. An equipment-hoisting method was designed that was different when compared to the S/S at underground MRT stations. Equipment hoisting in confined areas as above-mentioned situations is extremely difficult, making common lifting methods unsuitable. To resolve this, the CTCI team devised a special lifting method, which is detailed below. First, a movable steel platform is prepared. It is then craned up to the elevated working space. With one end of the platform fixed to the work opening using steel wires, the other end is suspended on the crane until the equipment is lifted onto the platform by another crane; this ensures that it can be moved into the station. In cases where the hoisting working space is too small, the equipment must first be set and fixed onto the platform prior to craning up the moveable metal platform. It is then hoisted up along with the platform to the working space. Following that, one end of the platform is fixed onto the working space before the equipment can be pulled into the equipment room and set in place.

Technical Matters

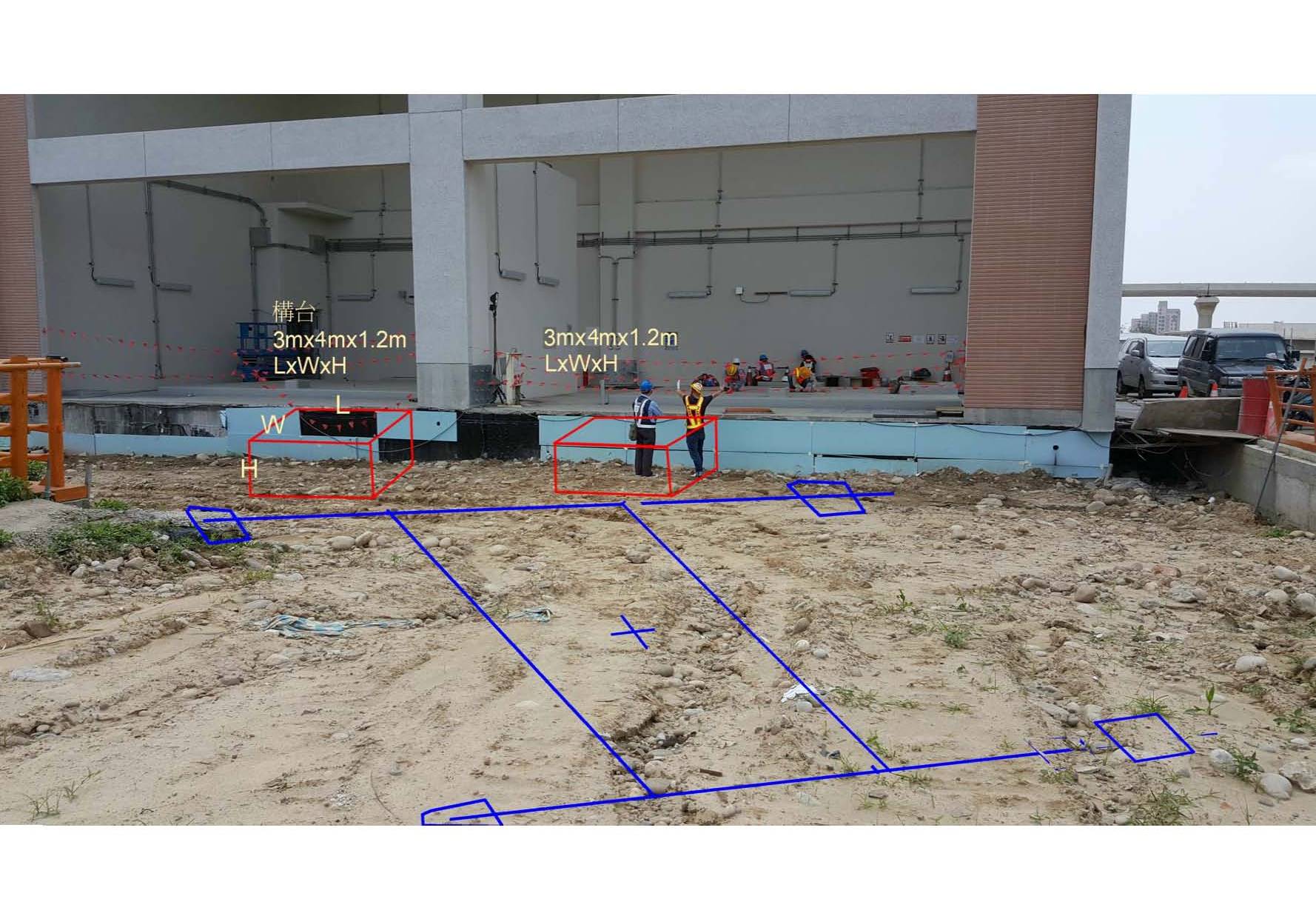

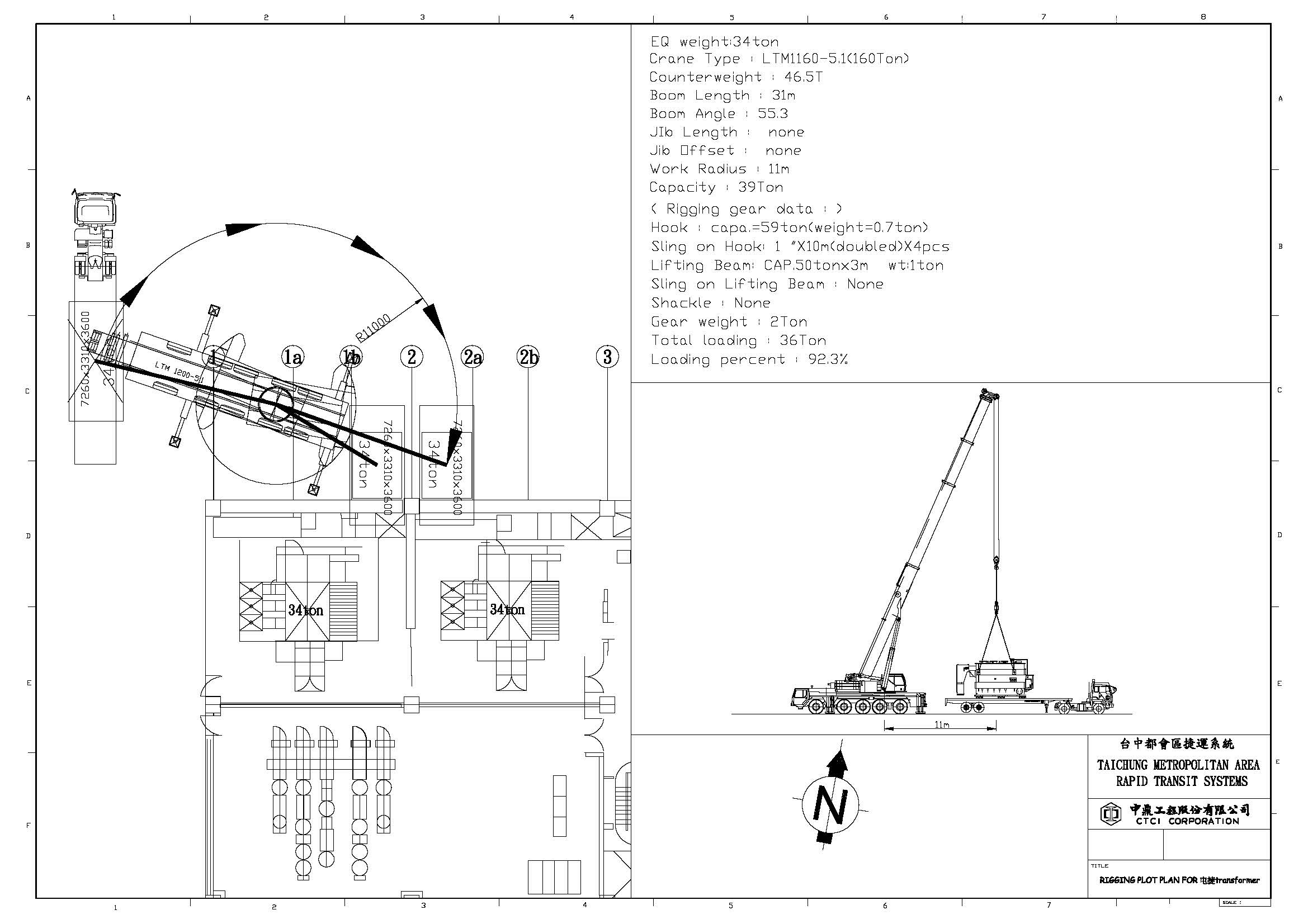

Software Used to Calculate and Simulate Safe Hoisting for 161kV Transformer at the BSS

There are two BSS for the Taichung MRT system. The 161kV transformer is the largest and the heaviest equipment at the BSS, rendering its delivery the most challenging of the project. Accessories and insulation oil must first be removed from the main transformer so as to reduce the net weight to 34 tons and to make moving easier. A 1-meter-deep lower and 20-meter-wide piece of land sits between the main road and the transformer yard of the BSS. Thanks to the hoisting software, calculations and simulations can be made by taking into account various on-site environmental parameters, the hoisting equipment, and the hoisted object so as to derive a feasible and safe hoisting procedure. Once the on-site surveys and simulations are completed, steel plates are used to cover the soil in order to stabilize the H beams that reach the same height as the transformer yard, and to cover with the steel platform. Then, steel pipes used as rollers are laid on the platform, so that the transformer can be lifted from the main road onto the platform using a 160-ton crane. Finally the transformer is pulled over the rolling steel pipes into the yard and positioned in place. The large and heavy equipment used in the MRT’s power supply system means that moving and hoisting activities are inherently highly risky. To prevent accidents and unforeseen developments within confined spaces, CTCI plans every detail in advance

Smarter Engineering

Integration Control on E&M Systems

Civil and E&M engineering are essential to the MRT system. In particular, the E&M system is considered to be a core component, along with EMU, power supply, signaling, and communications. The integration of E&M engineering impacts the success of the entire MRT system. Therefore, many complicated issues of interfacing subsystems must be carefully integrated and managed to ensure that the entire system reaches maximum efficiency. The control of the MRT system’s interface consists of a few key factors: (1) Functionality: for example, the communications protocol, statistics data exchange, power capacity loading requirements, and interlocking controls, etc.; (2) Physicality: for instance, embedded conduits, reserved openings, foundation for the E&M equipment, and the E&M room allocation, etc.; (3) Environment: for instance, electromagnetic interference, heat release, vibrations, and noise, etc.. Interfaces between E&M and E&M contractors are distinguished from interfaces between E&M and Civil contractors, depending on the various matters raised during the progress of the project. While the former deals with issues among E&M system contractors, the latter raises matters that are relevant between E&M system and civil engineering contractors. Interface control is highly critical not only to resolve technical issues constantly raised among the contractors but also to take proper management tools for planning, organizing, auditing, and communications all along.

“To cope with strict PTS (Particular Technical Specifications) of the contract, hoisting the equipment at the confined sites, and highly controls for QA & HSE demand, all equipment must be inspected, tested, and verified at various stages to ensure the integrity of on-site safety conditions. CTCI has made every effort to manage and review our activities on a monthly, weekly and even daily basis to evaluate the progress of our activities and the status of the interface, installation, and testing. It is through this rigorous process that we can ensure that the project is fully coordinated, cooperation with the required partners run smoothly, and QA/QC procedures are strictly followed. We are determined that the quality of power energization will be achieved as scheduled to meet the satisfaction of our clients.”

CTCI PM Torrin Chang of Taichung MRT’s Power Supply Project