Markets

Advanced Technology Facilities

With extensive knowledge and experience in global EPC, CTCI provides comprehensive engineering and construction services for advanced technology facilities. CTCI has plenty of experience in Front-End Engineering Design (FEED) and construction of advanced technology facilities, both new and revamped alike. The company specializes in plot plant arrangement, MEP, utility, and HVAC system implementation. CTCI is committed to serving every client with state-of-the-art technologies.

Our expertise

- Feasibility study of advanced technology facilities (new or revamping)

- Construction of advanced technology facilities (new or revamping)

- Front-End Engineering Design (FEED) of advanced technology facilities

- Procurement and construction management of advanced technology facilities

- Engineering, procurement, construction and commissioning (EPCC) of advanced technology facilities

- Cleanroom design, engineering, and construction

Market coverage

- Foundry industry

- Communications industry

- Optics industry

- Computer & accessories industry

- Precision inspection business

Our work

■ Semiconductor

World-Class Semiconductor Fab Project, USA

CTCI´s Service : A&E, GC, CM

Our client is the world’s leading semiconductor foundry provider, and the project is their first semiconductor facility in the United States.

CTCI leveraged our global resources and combined them with the local expertise of CTCI America to deliver comprehensive overseas construction services.

World-Class Memory Solution Construction Project, Taiwan

CTCI´s Service : EPC Lump sum

Our client is the world’s leading memory provider with a long-standing presence in Taiwan. Despite high global memory inventory levels in 2022, they launched this project, demonstrating their strong commitment to further investing in Taiwan. The project also features newly implemented systems to enhance wastewater treatment efficiency, contributing to Taiwan's environmental sustainability efforts.

■ Data Center

CSP Data Center Construction Project (19.2MW), Taiwan

CTCI´s Service : EPC Openbook

The project represents the second data center in Taiwan for a U.S. cloud service provider (CSP), with a data capacity of 19.2 megawatts (MW).

Vantage Data Center Construction Project (16MW), Taiwan

CTCI´s Service : P+C Openbook

Vantage is the hyperscale colocation data center provider, and this project located in the Taoyuan, Taiwan. The 16MW facility can accommodate both cloud and high-density deployments and can support liquid cooling.

■ EMS

Electronics Manufacturing Services

Foxconn High-Tech Plant Design Project, Vietnam

CTCI´s Service : A & E

Located in Vietnam, the high-tech factory design project supports the client’s adoption of the "China+1" strategy, establishing one of the new production base in Southeast Asia to diversify operational risks. Design services for the project are provided by CTCI Vietnam.

Foxconn Bengaluru EMS Plant Construction Project, India

CTCI´s Service : EPC Openbook

Located in Bengaluru, India, the EMS factory EPC project supports the client’s adoption of the "China+1" strategy, establishing one of the new production campus in India to diversify operational risks. Design services for the project are provided by CINDA (CTCI India).

■ ATF Related Project

EMC CCL Plant Construction Project, Malaysia

CTCI´s Service : EPC Openbook

Our client is the world’s leading high-end CCL (Copper-Clad Laminates) provider, and the project is their first manufactory plant in Penang, Malaysia.

The first phase of the plant will deliver a monthly production capacity of 600,000 sheets.

Molicel Lithium Battery Plant Construction Project, Taiwan

CTCI´s Service : EPsCm (CTCI SEC : MEP EPC)

CTCI and CTCI SEC are contracted by Molie Quantum Energy Corporation, part of Taiwan Cement Corporation (TCC) Group, to build in Kaohsiung a lithium battery factory, the first “Gigafactory” of its kind in Taiwan. The facility adopts advanced processes and equipment to produce high-performance nickel-cobalt-manganese (NCM) batteries with an annual capacity of 1.8 GWh, sufficient for producing long-range batteries for 24,000 EVs per year. The advanced production processes enhance Taiwan’s energy storage industry, expand its global market share in the super battery sector, and integrate into the EV supply chain, promoting the development of green energy for the nation. This new Gigafactory is certified as Gold-level green building by LEED and EEWH.

Foxconn Battery Center Construction Project, Taiwan

CTCI´s Service : EPC Openbook

The project is located in the Ho Fa Industrial Park in Kaohsiung, and this Battery Center serves as Foxconn Group’s first global battery manufacturing base. The center manufactures Lithium Iron Phosphate (LFP, LiFePO4) batteries with a capacity of up to 1 GWh, catering to the needs of EVs, and energy storage applications.

SDP Gen 10.5 LCD Cleanroom Construction Project, China

CTCI´s Service : EPC Lump sum

The project is a 10.5-generation LCD display panel manufacturing plant for SDP (超視堺) in Guangzhou, China. CTCI subsidiaries (CTCI Shanghai & CTCI SEC) jointly executed cleanroom construction, achieving the highest class rating of Class 10.

■ Non ATF Related Project

Water Reclamation Plant for Semiconductor Fab, Taiwan

CTCI´s Service: DBOO (Design-Build-Own-Operate)

The world’s first facility to recycle fab wastewater for reuse in semiconductor manufacturing was successfully developed through the collaboration of TSMC, ITRI, and CTCI. CTCI provided a comprehensive, one-stop reclaimed water treatment solution, encompassing investment, design, procurement, construction, and 20 years of operations under a DBOO model. The plant utilizes energy-efficient and low-impact biological treatment technologies, delivering substantial energy savings, carbon reduction, and environmental sustainability. It stands as a benchmark for sustainable development within the science park.

Waste Solvent (W-IPA) Recycling Plant, Taiwan

IPA is widely used as cleaning solvent in semiconductors industry, ECOVE (A subsidiary of CTCI) purifies the waste IPA (5%) into electronic-grade IPA (99.5%).

Purification of W-IPA

.W-IPA 5% → 85% → 99.5%

.Distillation and Separation

.Extraction and Distillation

.Membrane Separation (Vapor Permeation) → Clean Tech

This reduces the production of 1,500 metric tons of IPA annually. ECOVE also assists clients in setting up customized on-site waste solvent treatment facilities. These comprehensive, tailored solutions promote circular economy practices, achieving both economic and environmental benefits.

■ Non Projects

Clean Room Experience

Classification:

Class 10, 100, 1000, 10k, 100k

Accumulated Total Area (5yrs) :

+240,000 m²

Green & Smart Building ( CTCI 2nd Headquarters, Taiwan )

Designed and constructed by CTCI Group, the company’s 2nd headquarters integrates advanced smart and green technologies.

It features intelligent air conditioning, water, and power supply systems, and facility management solutions. The building has earned dual certifications, including Taiwan’s Green Building EEWH Diamond and Smart Building Diamond standards, as well as the U.S. LEED Gold certification. Completed in 2021, this office building embodies energy efficiency, sustainability, and harmonious coexistence with the environment.

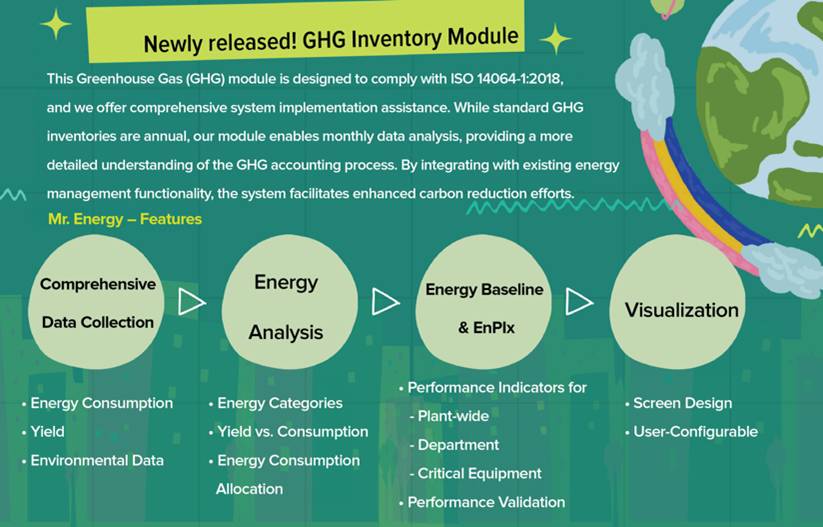

Mr. Energy (Energy Management System)

“Mr. Energy” is an energy management system developed by CTCI-ASI, collecting real-time data on energy consumption, temperature, and equipment performance. The intuitive web-based dashboard allows clients to monitor and optimize operations in real time. Recent enhancements include a carbon footprint estimation feature, which calculates emissions from various activities and generates compliance-ready audit reports, helping enterprises to meet energy-saving and carbon reduction goals.

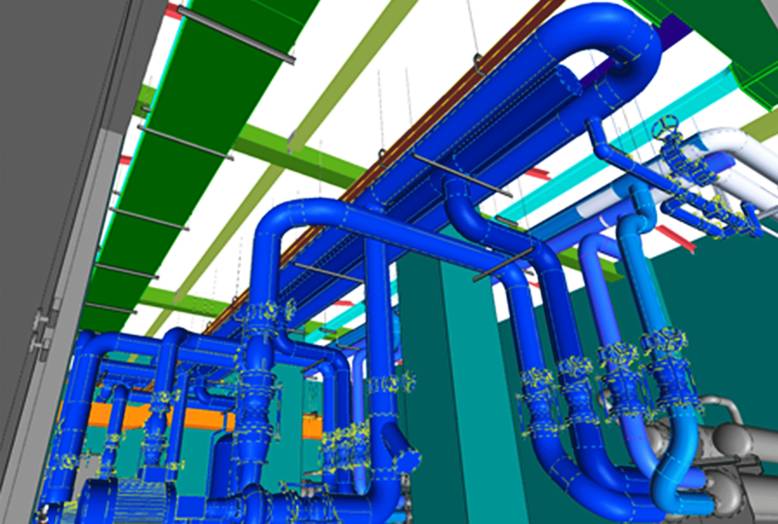

Construction Management-BIM

CTCI integrates BIM technology for digital design and lifecycle management of construction projects. BIM visually represents construction details, enabling CTCI to reduce errors, omissions, and material waste during construction, while minimizing design changes and costs. Additionally, it decreases paper usage, contributing to energy efficiency and carbon reduction.

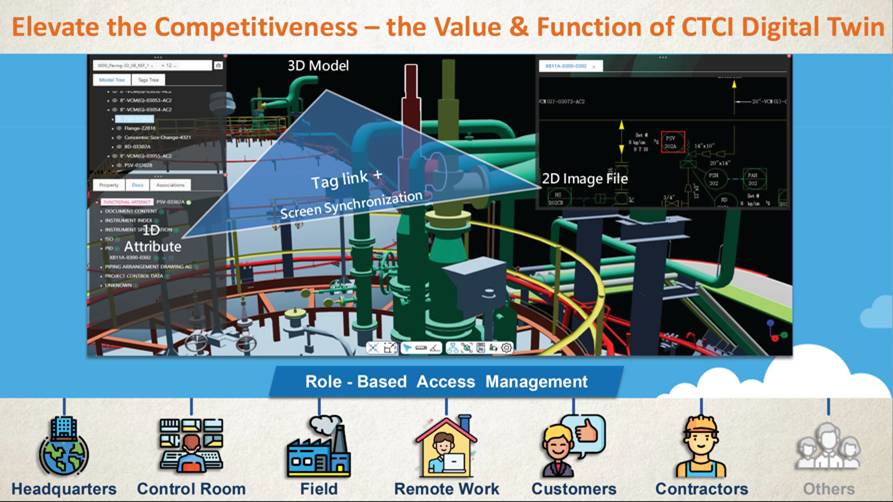

CTCI Digital Twin

By linking construction data to 3D models, CTCI creates a digital twin for turnkey projects. Upon project completion, clients receive not only a physical factory but also a digital factory. This digital delivery integrates maintenance and operational systems with the digital twin, enabling efficient digital operations and maintenance (Digital O&M). The system is cloud-based, requiring no installation or setup, and offers intuitive browser-based access to design information.