Sustainable Engineering

Environmental and Resource Management

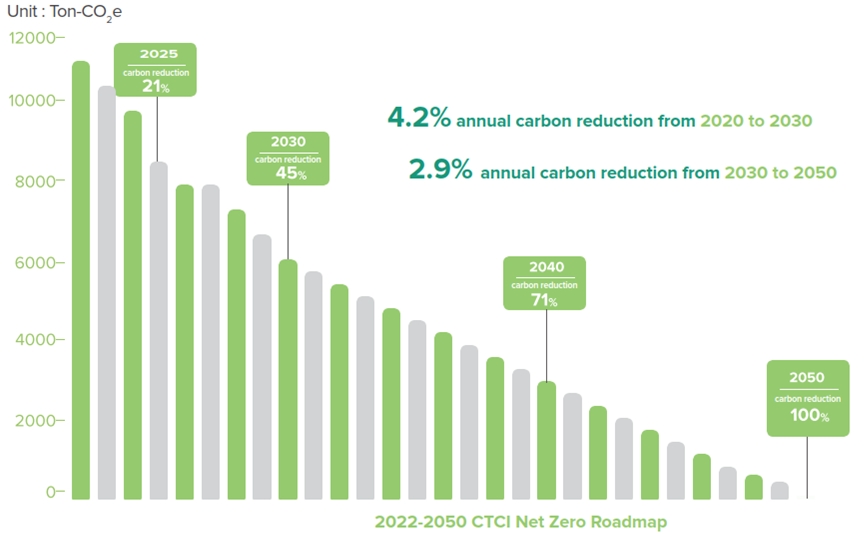

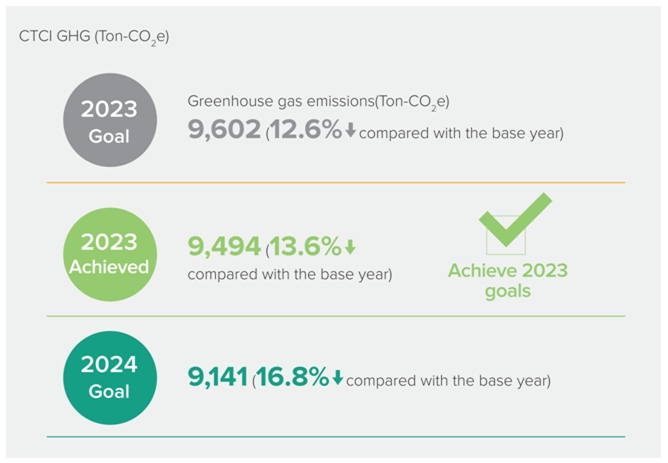

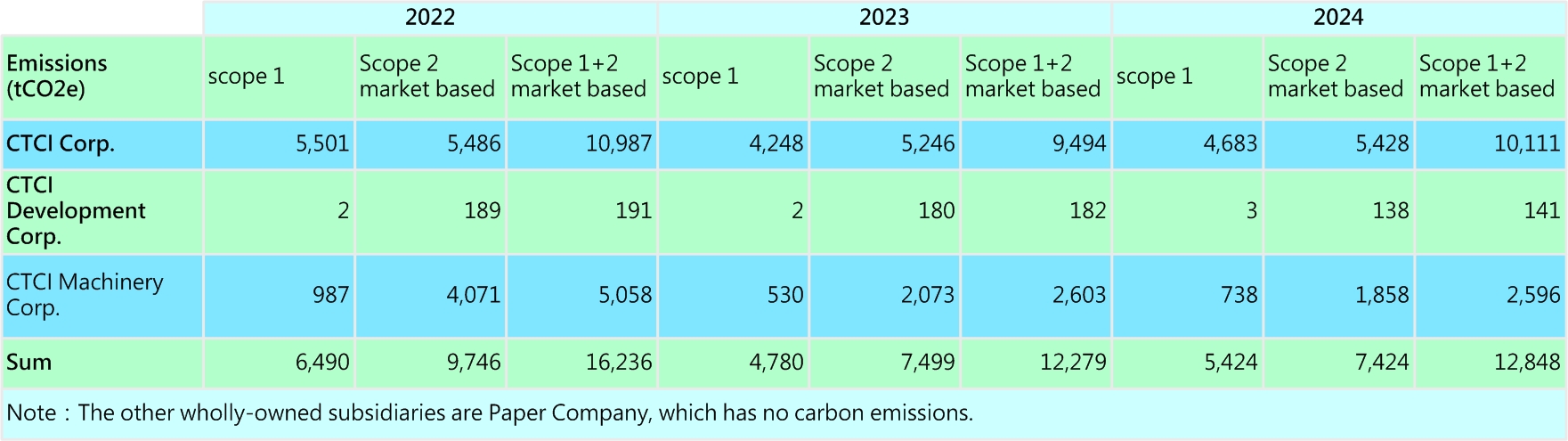

Carbon reduction roadmap with 2022 as the baseline year (annual updates on actual achievements)

► CTCI's carbon reduction performance

► Fulfillment of carbon reduction at SBTi-aligned sites

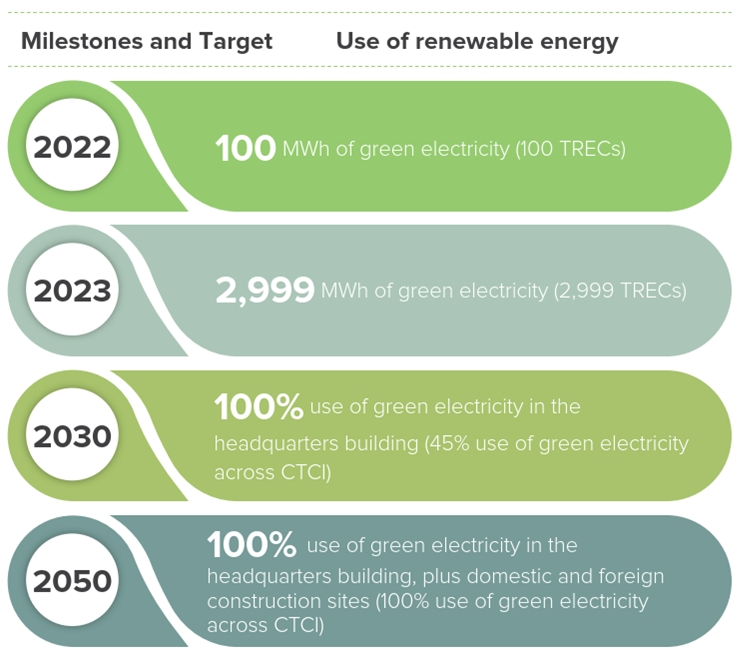

Green electricity usage ratio (annual update)

► Renewable energy consumption and targets

► Renewable electricity usage of headquarters

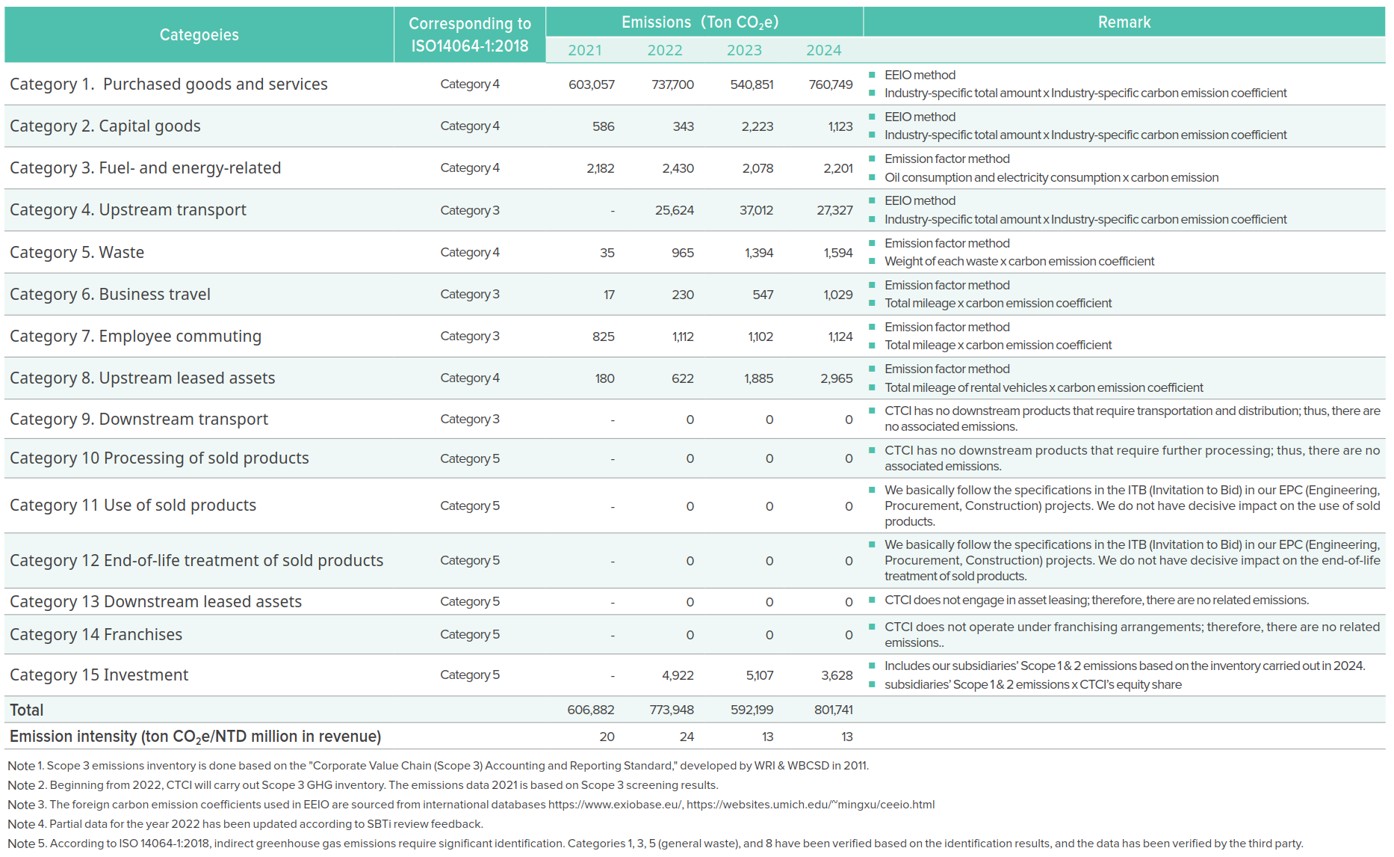

Scope 3 Greenhouse Gas Emissions

Transportation

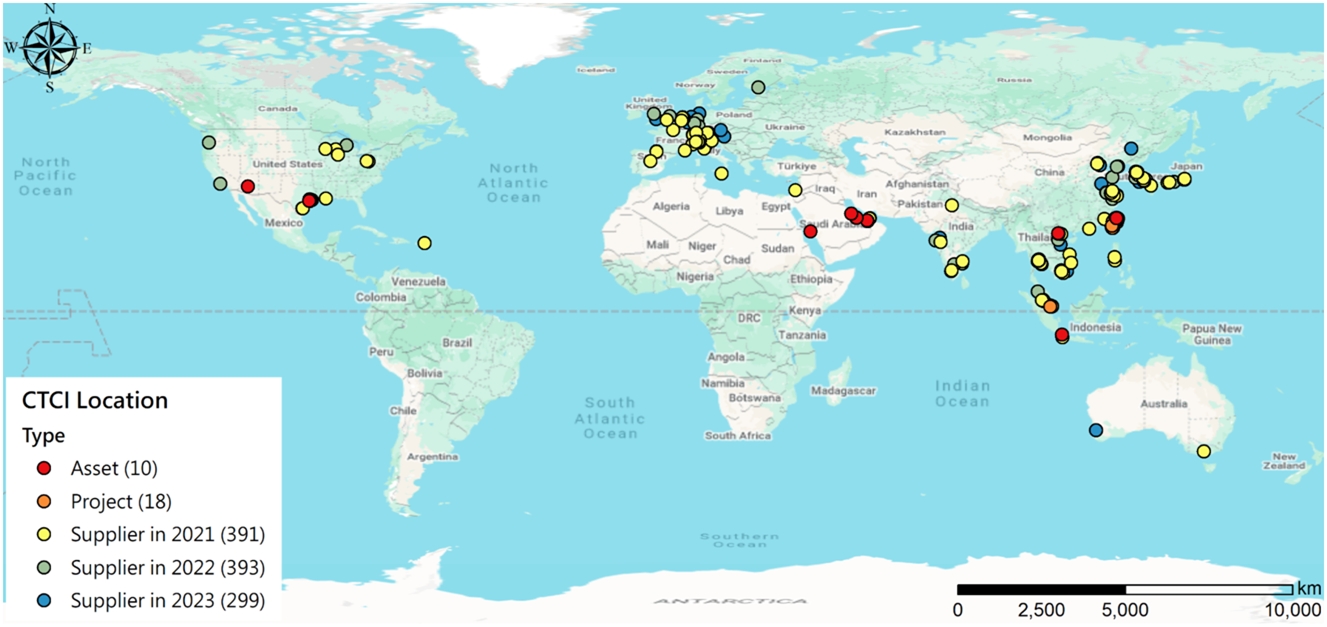

When selecting transportation contractors, CTCI prefers the ones who share our vision. We prefer those who have ISO 14001 Environmental Management Certification. To reduce the environmental impact from transportation, we use local equipment and materials whenever possible and procure locally to reduce transportation distance and conserve energy. We prioritize low-carbon, low-sulfur and low-pollution forms of transportation, such as prioritizing sea transport over air transport for energy conservation, while requiring shipping contractors order ships from those who adhere to the "2023 IMO Strategy on Reduction of GHG Emissions from Ships" that imposes a minimum carbon emissions reduction target of 20% by 2030 and 70% by 2040, and that demands the use of ships powered by low-sulfur fuel oil by 2020 in the purchase order. In terms of sea transportation, since newly built ships have better fuel efficiency and can conserve oil, we use only those ships that are aged less than 15 years. During LCL or consolidation, cargoes with close delivery locations or shipment periods can be combined into a single batch for transportation if the project schedule allows.

Biodiversity

The primary operational base of CTCI is the headquarters building and global construction sites, which are located in areas that do not involve protected biological habitats or regions of high biodiversity that hold significant ecological value for indigenous peoples and local communities. The Company emphasizes ecological environment, cultivates suitable vegetation, promotes greening, and mitigates environmental impact. In the execution of various engineering projects, equal importance is placed on the ecological protection of the project site, encompassing ecological assessment and monitoring activities at all stages, including design and construction. All ecological data collection, investigation, and analysis are conducted by qualified ecological personnel. They assist in integrating the concept of ecological conservation into engineering design, propose specific ecological protection measures, and ensure their implementation in the project. Before construction begins at global sites, we conduct ecological surveys and environmental impact assessments, fully considering local species, habitats, and ecosystems during the project design phase. Conservation strategies that include avoidance, minimization, mitigation, and compensation for environmental impacts are then implemented. CTCI's ”Biodiversity and Zero Deforestation Policy Commitments” was adopted by the Board of Directors.

Policy Commitment Download PDF Policy Commitments

► Ecological/Environmental Conservation Strategy and Planning

CTCI establishes a dedicated unit, the Sustainability and Net Zero Office, in collaboration with the Sustainability and Net Zero Implementation Team, to jointly promote sustainability-related matters across departments. The unit operates under the supervision of the Sustainability Superintendent. The Sustainability Superintendent and the Chief Sustainability Officer regularly report the outcomes of nature conservation and biodiversity protection to the Sustainability and Information Security Committee established under the Board of Directors. CTCI has set targets for biodiversity conservation. By 2030, our operational sites aim to achieve No Net Loss (NNL) and adhere to Zero Deforestation standards. By 2050, our operational sites strive to achieve Net Positive Impact (NPI), while our value chain aims for No Net Loss and compliance with Zero Deforestation standards.

► Nature-related Financial Disclosures

In response to the global emphasis and evolving trends regarding biodiversity, CTCI has initiated the preliminary adoption of the Task Force on Nature-Related Financial Disclosures (TNFD) framework. Through the application of the LEAP methodology (Locate, Evaluate, Assess, and Prepare), we assess nature-related risks and opportunities to enhance our disclosure on financial aspects related to nature. The process planning instructions are as follows. For detailed results, please refer to the CTCI Climate and Nature-related Financial Disclosure Report.

► External initiatives and partners

To strengthen its influence on natural ecology and environmental protection, CTCI not only takes actions internally but also collaborates with external initiatives and partners, including various non-governmental organizations. Through these partnerships, CTCI actively invites its employees and their families to participate in initiatives aimed at raising public awareness and understanding of the value and importance of biodiversity conservation, and promote the mainstreaming of biodiversity.

TNFD Early Adopter

After TNFD finalized the final version of the framework in September 2023, it became the standard for companies to disclose natural risks and related strategies. CTCI promised to disclose the nature-related risks and strategies of company operations and became the first batch of TNFD early adopter companies in the world. From 46 countries around the world, there are 320 commercial and financial institutions have joined, and 14 companies from Taiwan are listed. The 2023 Climate and Nature-related Financial Disclosure Report published by CTCI was selected as a list of illustrative examples of reporting the TNFD, and only five companies in Taiwan were included.

Business for Nature initiatives

The initiative of more than 1,500 business and financial institutions from 86 countries, including CTCI Group, is calling for ambitious and collective action for nature. Healthy societies, resilient economies and thriving businesses rely on nature. Governments must adopt policies now to reverse nature loss in this decade. Together let's protect, restore and sustainably use our natural resources. The hope is to reverse nature negative by 2030.

Guandu Nature Park: Tamsui River Wetland Protection

CTCI collaborates with Guandu Nature Park for third year. Guandu Wetland is an important natural asset in Taipei City and national level wetland. The program begins with an introduction to wetlands, followed by a professional guided tour of different wetland habitats. Through active participation, participants engage in wetland conservation efforts by eliminating invasive species like the bitter vine (Mikania micrantha), reducing their impact on native species, also performing pool maintenance and removing wetland silt. We contribute to the protection of biodiversity in the Guandu Wetland.

A total of 61 group colleagues, their families and external supplier partners participated in this event to implement environmental actions together, protect Tamsui River and wetlands, and strive to maximize sustainable influence from the perspective of the value chain and make concrete contributions to biodiversity.

Urban Explorers Biodiversity Collaboration Project

CTCI, together with Zhishan Cultural and Ecological Garden and nine cultural exhibition halls in Taipei City, jointly practice ecological conservation, and join hands with the public to become urban explorers. Together, they participate in surveys and implement conservation plans to protect Taipei City’s biodiversity. Ecological surveys are carried out on average once a week. Through continuous data accumulation, we can roughly compare the differences in species richness in rural areas, waterfront areas, and urban core areas. The number, location, and photos of organisms are recorded in ecological database systems such as eBird, which regularly establishes records of Taipei City’s biodiversity. In 2024, a total of 1,792 people participated in the survey, and nearly a thousand species of organisms were surveyed, with fruitful results.

Tree and creek protection actions in Wufengang Creek

Beside Wufengang Creek, it is an old river channel where Shuang Creek flows into the Keelung River. It is the only natural river channel in Taipei that is not cemented, and the Linong Wetland where the basin is located is very ecologically rich. CTCI collaborates The Beautiful Waterways Association, which is the adopter of Wufengang Creek, Volunteers removed the invasive alien species, and protected the precious plant Barringtonia racemosa. They also conducted water quality testing and creek cleaning by raft, and participated in the Wufengang Creek Land Art Festival to encourage colleagues to pay more attention to natural ecology and environmental protection.

Green New Life - Protecting Habitats in Taiwan

Collaborating with OKO Green continuously, we combine fair trade products with habitat conservation, encouraging employees to increase their green consumption. We pledge to donate 10% of the purchase amount to the Taiwan Environmental Information Association, safeguarding 3% of Taiwan's habitats and making our contribution to ecological preservation in Taiwan.

New collaboration with BlueMagpie Tea Social Enterprise will integrate the same watershed area with "watershed recovery" as the core, and improve biological habitats through pesticide-free farming and consumer power.

Carbon Footprint Promotion Plan

As a non-manufacturing engineering services company, CTCI does not produce a single, fixed product, making it difficult to directly implement product carbon footprint assessments. However, in response to the urgent issue of carbon reduction, CTCI actively participates in and provides project-based carbon footprint management services for clients. For example, in 2022, CTCI conducted a "Solid-State Battery Product Life Cycle Assessment Consulting Project," assisting the client in evaluating the product's life cycle carbon footprint and subsequently proposing carbon reduction strategies and improvement suggestions. This demonstrates CTCI’s professional expertise in carbon footprint management and reflects its support and contribution to clients' sustainable development. In addition to project services, CTCI is actively developing Product Category Rules (PCR) for the carbon footprint of Turnkey Services, aiming to reduce the variability caused by different engineering scales and scopes, while ensuring comparability and reproducibility. The second draft of the PCR has been completed and submitted to the Ministry of Environment for review. The official release is expected in 2025. Carbon footprint evaluations and management will then be carried out in accordance with this standard, along with obtaining ISO 14067 carbon footprint verification and carbon labeling.

Carbon Pricing Implementation

CTCI continuously monitors global and domestic trends in carbon pricing and adopts internal carbon pricing as a tool for managing climate change risks. This approach supports the promotion of carbon reduction actions and the enhancement of energy efficiency, ultimately aligning with the near- and long-term reduction targets approved by the Science Based Targets initiative (SBTi). These efforts guide the company toward achieving net-zero emissions at office sites by 2030 and at production and service sites by 2050. The internal carbon price is established with reference to international carbon pricing trends, including the World Bank’s State and Trends of Carbon Pricing report, the EU Emissions Trading System (EU ETS), and Taiwan's carbon fee framework. CTCI also considers national net-zero outlooks, regulatory developments, and industry best practices for pricing and implementation strategies. In 2022, the internal carbon pricing mechanism was developed, and by 2025, the price will be adjusted to USD 100 per tCO₂e (equivalent to approximately TWD 3,000 per tCO₂e). Through a shadow pricing mechanism, carbon costs are integrated into business operations and decision-making processes, covering both Scope 1 and Scope 2 greenhouse gas emissions. Each business unit calculates its emissions based on operational control, and carbon pricing is incorporated into performance evaluations for both managers and project personnel. This strengthens organizational awareness and response to climate-related issues. By implementing internal carbon pricing, all business units are encouraged to proactively consider the risks and management costs associated with carbon emissions during their daily operations. This drives the execution of tangible carbon reduction measures and ensures the effectiveness of internal carbon pricing as a management tool, providing a solid foundation for long-term low-carbon transformation.