Sustainable Engineering

Strengthen Climate Resilience

Climate-Related Financial Disclosures

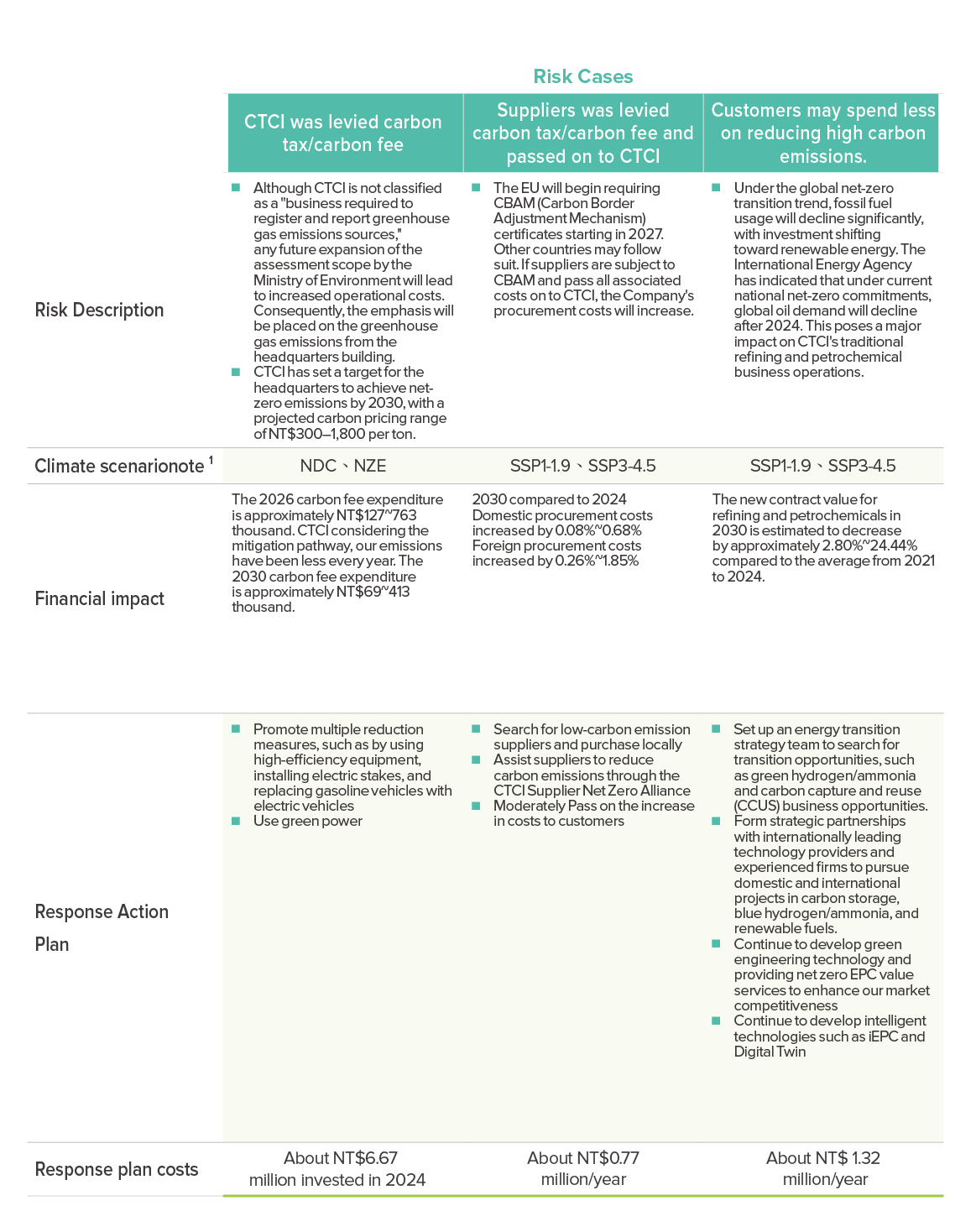

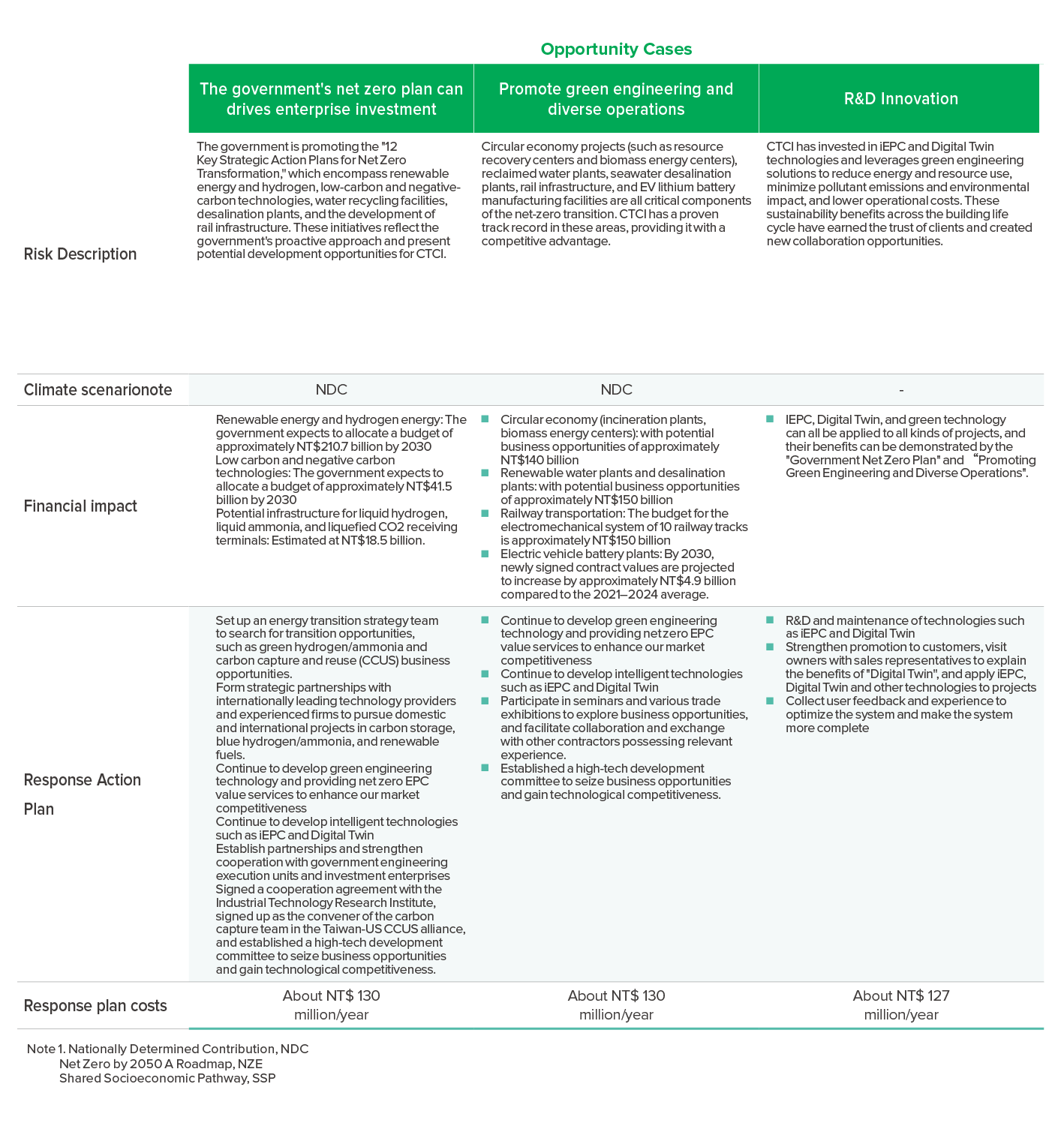

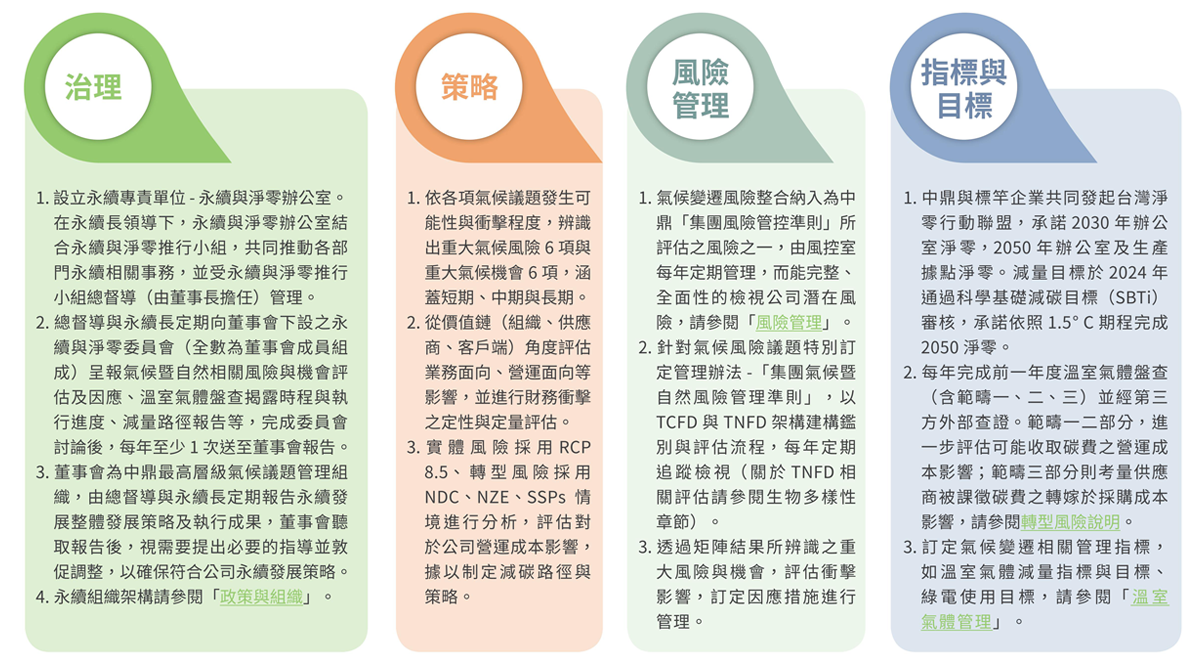

To assess the physical and transition risks related to climate change, measure and calculate the climate change impacts that CTCI, its suppliers, and value chain partners face, and promote climate-related financial disclosure and communication among stakeholders, CTCI has incorporated the TCFD and TNFD frameworks in its sustainability management. CTCI recognizes the importance of climate issues and proactively engages in climate risk and opportunity assessment. CTCI officially signed up as a TCFD supporter as early as October 2022 and uses the TCFD framework to examine potential climate risks and opportunities for management to reduce risks and seize development opportunities. Since 2022, CTCI has published Climate-related Financial Disclosure Reports for two consecutive years. In 2024, CTCI further advanced its efforts by releasing the Climate and Nature-related Financial Disclosures Report (TCNFD Report).

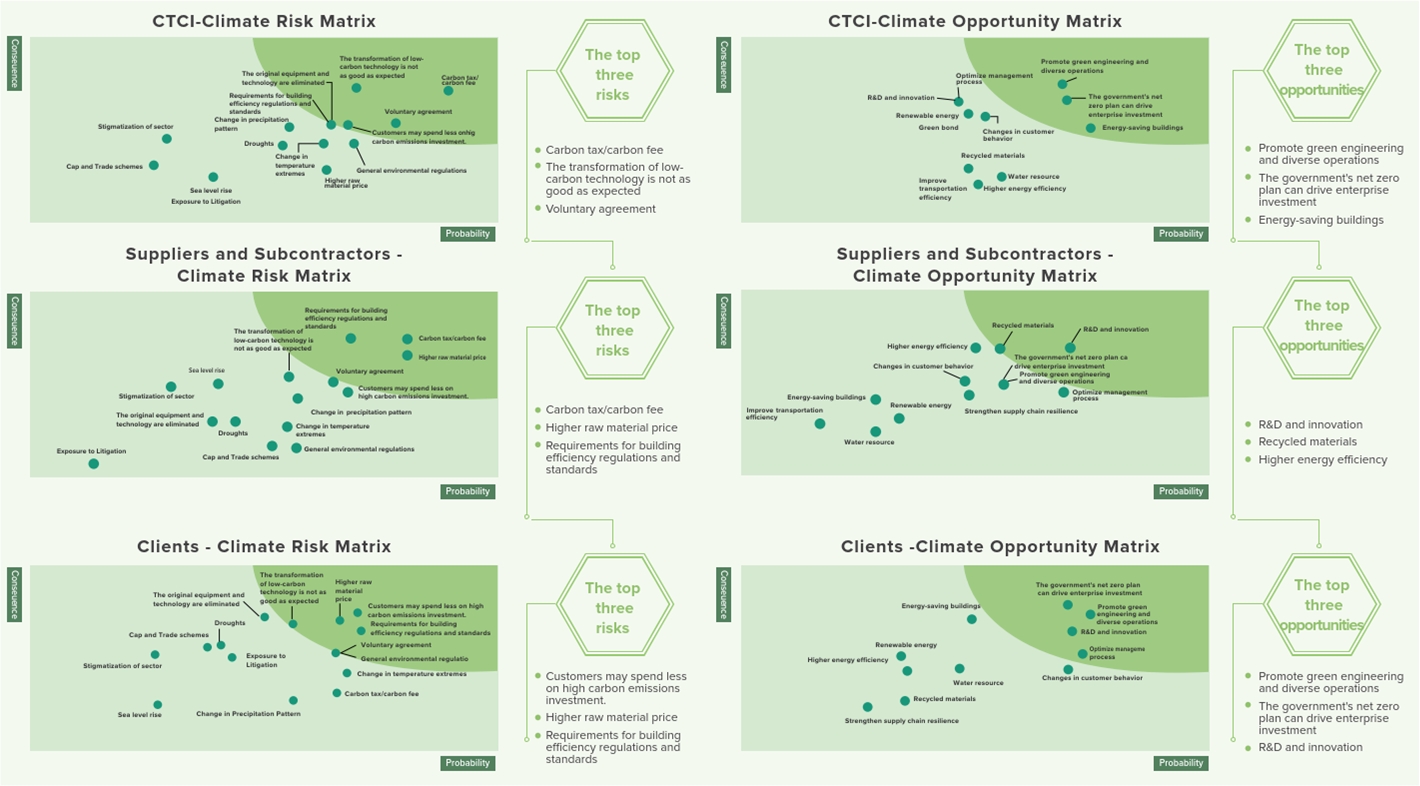

Identify major climate risks and opportunities

CTCI used its own operations as the scope of assessment and, with reference to TCFD categories of physical risks (short- and long-term) and transition risks (existing and emerging policies, regulations, technologies, markets, and reputational factors), designed a survey to identify impacts from a value chain perspective—covering the organization, suppliers, and clients. The results were used to evaluate business and operational impacts, and to develop a climate risk and opportunity matrix identifying major risks and opportunities in the short term (up to 2030), medium term (2020–2050), and long term (beyond 2050).

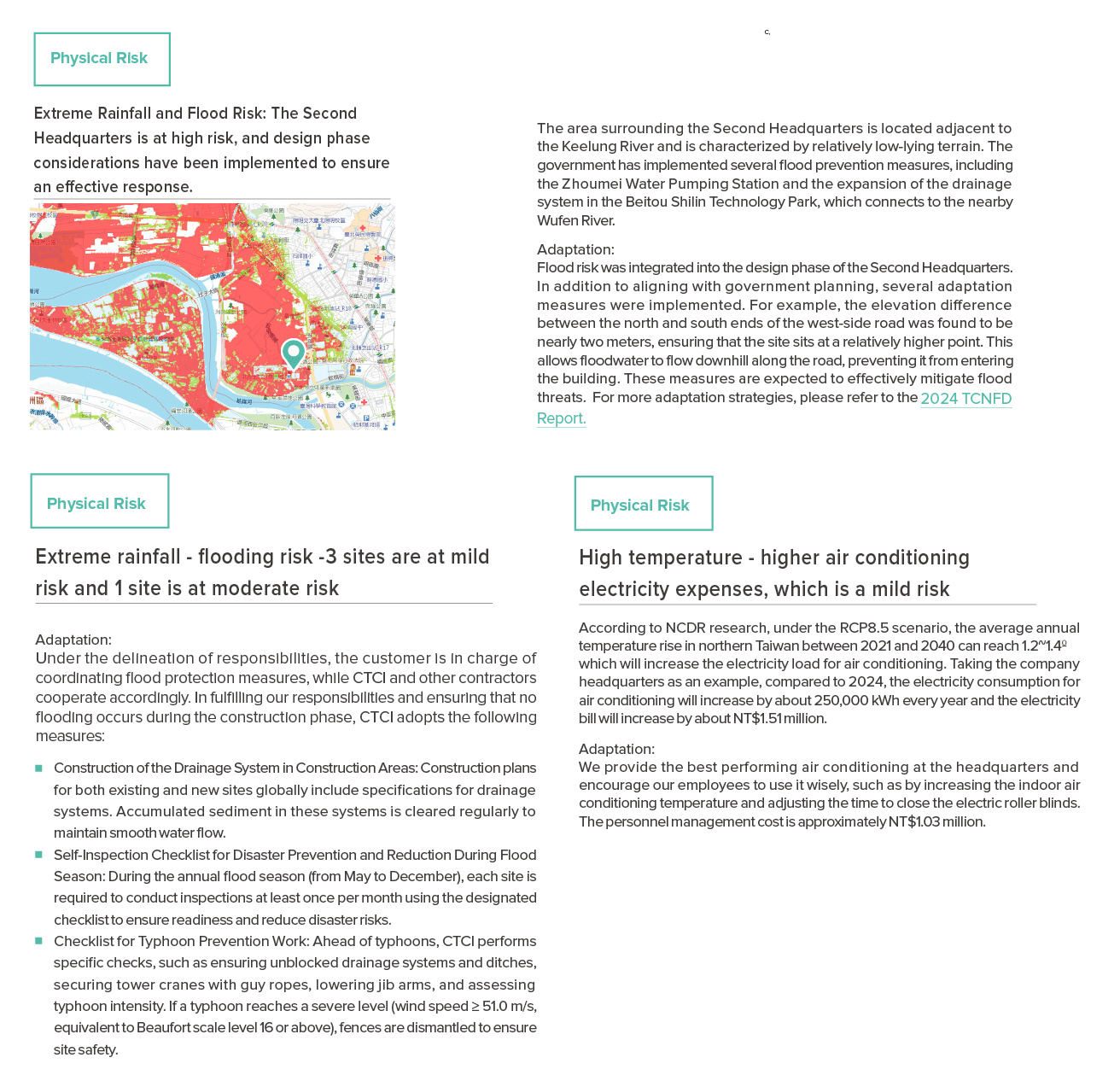

Physical Risk Assessment