Sustainable Governance

永續治理

Maintaining Resilient Supply Chain for a Sustainable Future

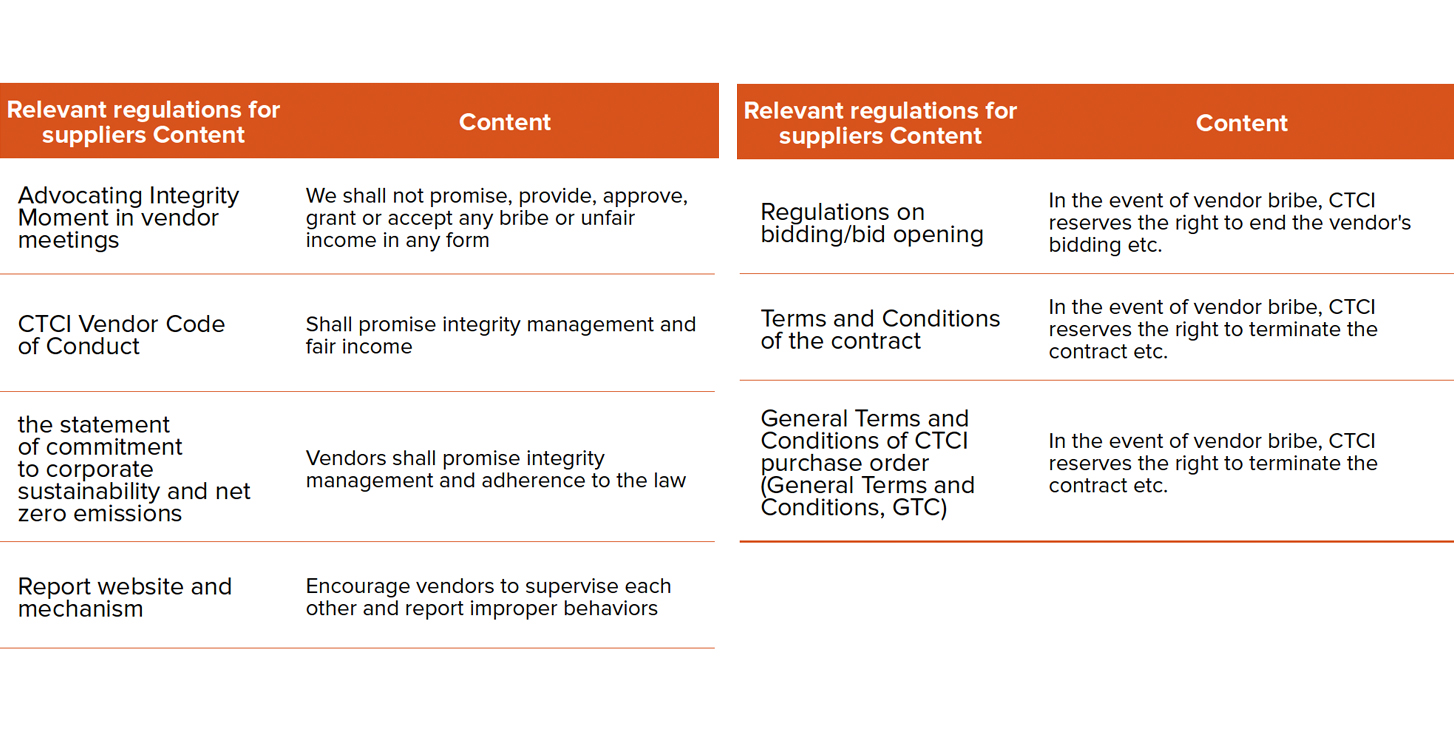

As a global turnkey engineering company positioned as "No. 1 in Taiwan and top 100 in the world," CTCI’s customer base covers industries such as oil refining, petrochemical, chemical, natural gas, power, transportation, steel, and environmental engineering. The company, which provides professional services such as feasibility analysis, planning, design, procurement services, equipment supply, construction, and commissioning, is located at the midstream of the overall engineering industry chain. By working with downstream suppliers such as materials, equipment, and construction firms, CTCI serves the upstream customers’ needs. Together, they form a complete industrial value chain. As of the end of 2021, more than 10,000 suppliers all over the world are working with CTCI. CTCI values the collaboration and joint growth with its suppliers, whom it views as its partners. Moreover, CTCI encourages its suppliers to become more sustainable and pursue common interests. Thanks to its exceptional performance, CTCI has won the Taiwan Corporate Sustainability Award (TCSA) Supply Chain Leadership Award, received A- score (Leadership Level) in its CDP Supply Chain Agreement assessment, received a score of 93 in the Dow Jones Sustainability Index (DJSI) Supply Chain Assessment, as well as other sustainability-related recognitions at home and abroad. In this respect, CTCI has become a role model for Taiwan's engineering industry. In the following paragraphs, we will briefly talk about CTCI’s strategies for sustainable supply chain development. 1.Set Up Sustainable Supply Chain Development Strategies CTCI’s strategies for sustainable supply chain development is based on an aim to meet client needs, as well as requirements on quality, HSE (health, safety, and environmental performance), price, and schedule delivery objectives. Given this aim, CTCI draws out four main strategies, including management with integrity, focus on employee rights, safety first, and local procurement. For this purpose, CTCI manages its suppliers through its Supplier and Subcontractors database and sets up a whistleblowing platform, so as to maintain a robust communication mechanism with them. 2.Set Up Supplier Integrity Management Mechanism CTCI is a company that values integrity and has a supplier integrity management policy in place. Based on a fair, just, and open manner, CTCI has set various codes and statements of commitment against corruption and ensuring suppliers' integrity, which are disclosed in ESG reports, company websites, publications, meeting and external activities, so that suppliers understand CTCI's policies in this regard.

CTCI’s Regulations for Supplier Integrity Management

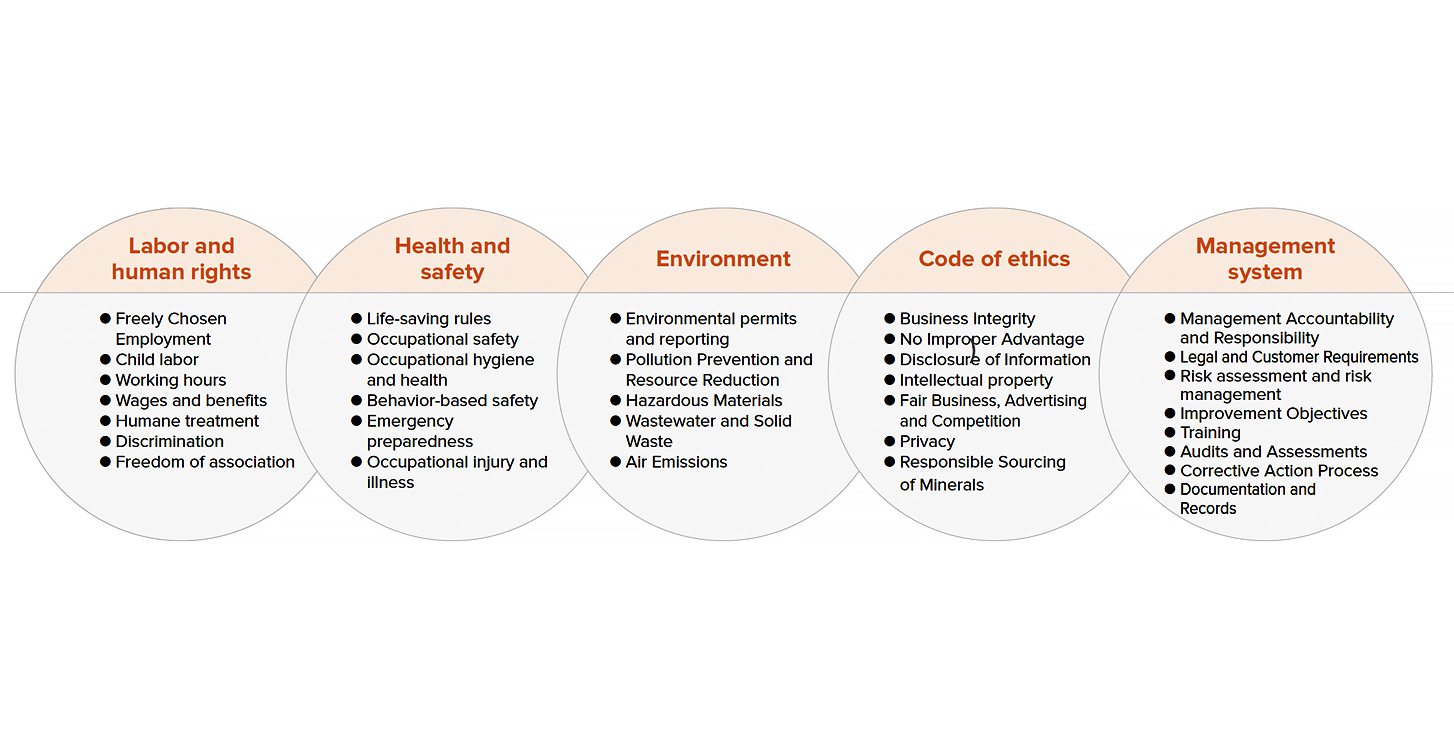

3."CTCI Vendor Code of Conduct" and "Letter of Commitment on Corporate Sustainable Operations and Net Zero Emissions" CTCI issued the first sustainability report in 2008 and has always been committed to the corporate sustainable development. We expect suppliers to share the same values. Therefore, we have established the CTCI Vendor Code of Conduct that includes five major requirements based on international initiatives and regulations. We require all suppliers, old and new, to follow such code, and also encourage them to ask their own suppliers to do the same, so that the entire industry chain can become more sustainable through mutual influences. Furthermore, CTCI requests that all prospective suppliers need to sign a "Letter of Commitment on Corporate Sustainable Operations and Net Zero Emissions." CTCI’s suppliers need to set targets of emissions reduction, disclose their greenhouse gas emissions, and reduce carbon footprints in phases. They also need to assess and disclose their dependence and impact on biodiversity, and reduce related risks. CTCI wishes to join hands with suppliers to support climate actions.

Five Major Requirements on Supplier Conduct

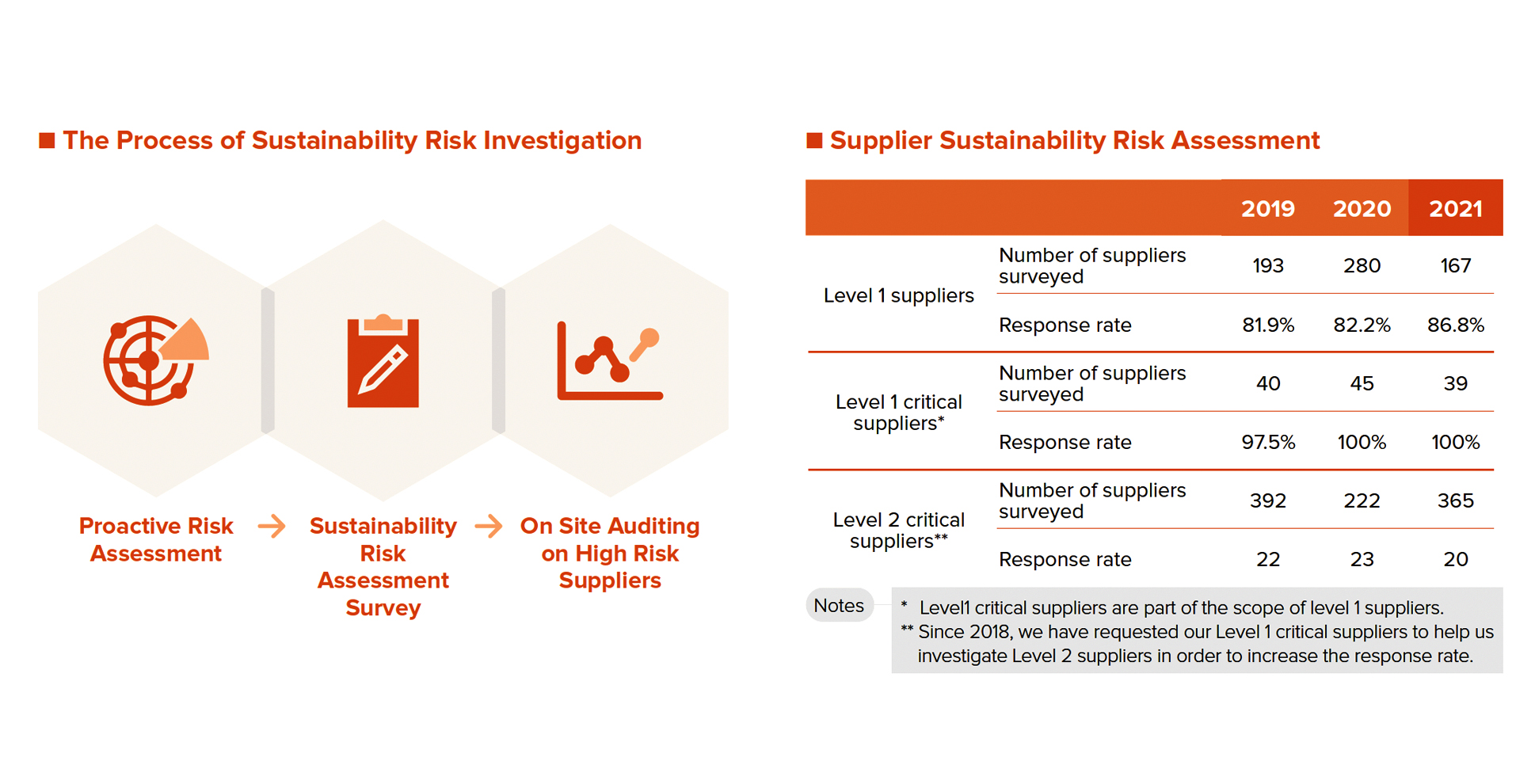

4.Sustainable Supply Chain Management Model and Risk Management CTCI has a robust supply chain management mechanism in place that helps it increase the sustainability and resilience of its supply chain against risks. The mechanism also helps improve supplier’s capability and performance in terms of sustainability.

CTCI Sustainable Supply Chain Management Framework

CTCI's supply chain can be divided into six major procurement categories: equipment, electrical engineering, pipelines, instrument and control, other category, and subcontractor services. As of the end of 2021, CTCI has worked with more than 10,000 suppliers all over the world. In order to properly manage such a large and complex supply chain, CTCI splits its suppliers into different levels. Level 1 suppliers are those whose cumulative transaction amount is among the top 95% of the current year, while those whose transaction amount pass the $3 million USD threshold are defined as critical suppliers. This categorization helps classify and effectively manage the overall supply chain status. As of the end of 2021, there are 167 Level 1 suppliers and 39 critical suppliers. To control the suppliers’ sustainability risks, CTCI would proactively review and determine such risks when they initially registered as suppliers. Review criteria include business permits, evidence of tax payment, company profile, project performance, service quality, and HSE certification. CTCI would then classify suppliers based on geographical regions and procurement types, before conducting risk assessment through on-site visits, particularly to firms located in China and India. Moreover, CTCI would request its suppliers to self-evaluate their sustainability risks through questionnaire surveys

Sustainability Risk Investigation and Assessment

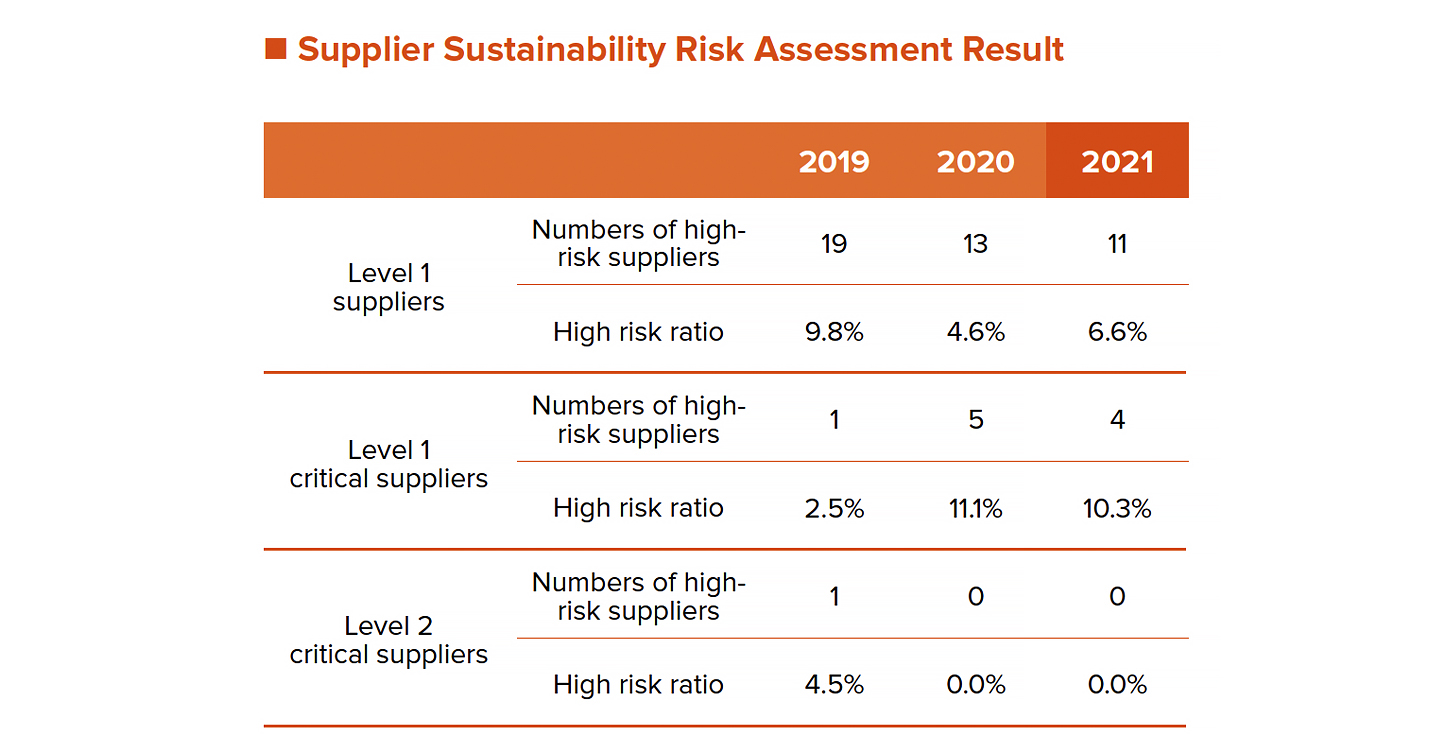

5.Supplier Impact Assessment Mechanism At CTCI, suppliers’ sustainability risks are reviewed from three factors: economic, environmental, and social factor. If a supplier meets any of the three risk factors and has not been certified to ISO 14001 and ISO 45001 standards, it will be viewed as a supplier with higher risk in sustainability. For suppliers with higher risks, CTCI would take appropriate mitigation measures, such as conducting on-site visits and audit to offer improvement suggestions.

Proportion of High-Risk Suppliers at All Levels in the Past 3 Years

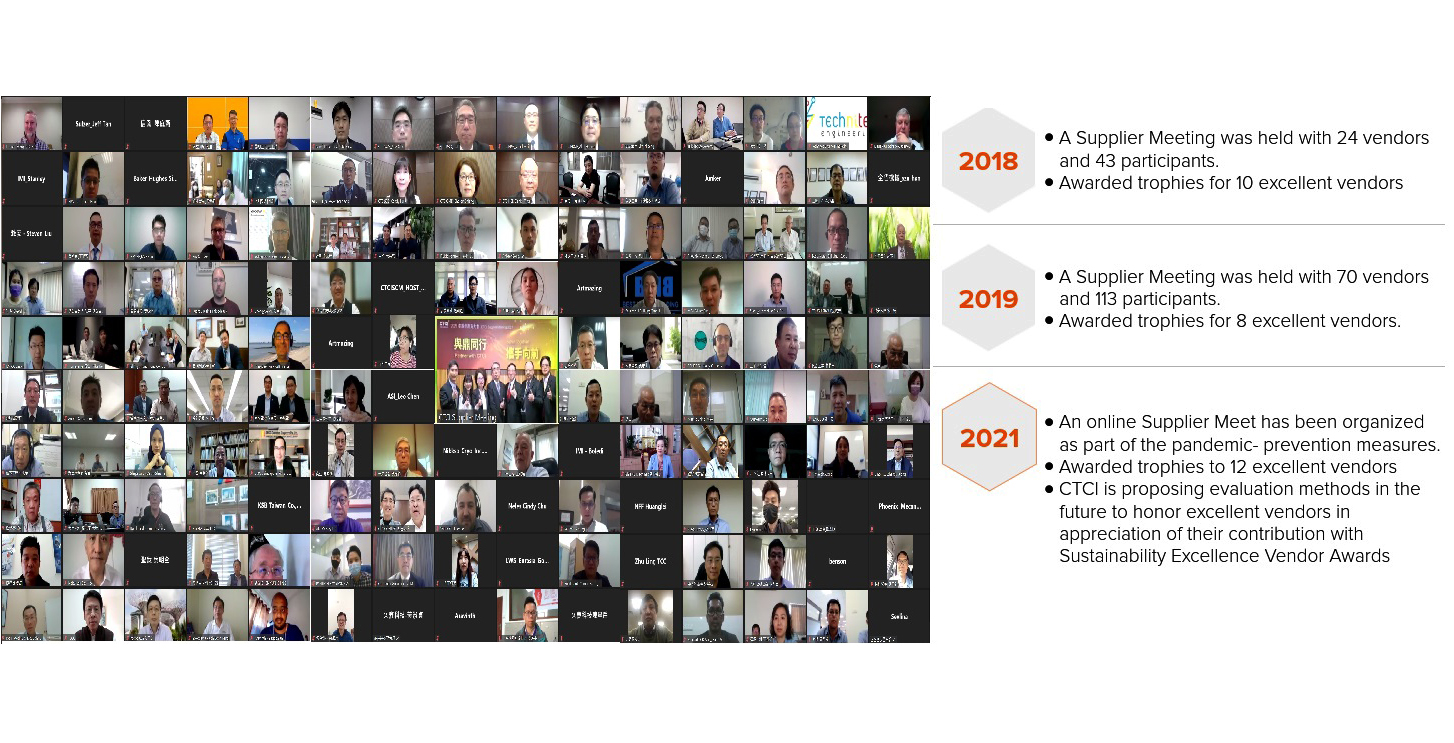

Besides measuring suppliers' sustainability risks through questionnaires, CTCI has developed suppliers' sustainability audit methods and audit procedures, with which it has conducted audits and counseling for high-risk suppliers to ensure that their risks can be effectively controlled and alleviated. Before conducting on-site visits, CTCI would give its staff proper training on sustainability auditing and issue self-assessment forms to the suppliers. In the case of high-risk suppliers, CTCI would conduct a re-audit the year following the identification of such risks, ensure suppliers understand the things that have been marked as high risks, and offer assistance to improve such problems. CTCI would continue to keep track of how the suppliers have improved, until they reach 100% improvement. 6.Establish Communication Channels and Enhance Suppliers’ Awareness on Sustainability To become a more responsible corporate citizen and increase the company’s influence in the field of sustainability, CTCI holds a Global Supplier Meeting each year, where it would talk about the importance of sustainable management and share the management results. Through a well-established assessment method, suppliers are classified into various categories (piping, equipment, trackwork, E&M, labor services), graded, ranked, and commended with Vendor Award for Sustainability Excellence. In 2021, the Global Supplier Meeting took place online due to the COVID-19 pandemic. In total, 106 domestic and foreign suppliers joined the event. This not only kept the supplier aware of ESG issues, but also minimized the disease risks, as well as reduced carbon emissions from air travel. Through Global Supplier Meeting, CTCI joins hands with suppliers towards a brighter and more sustainable future.

170 People Joined the Global Supplier Meeting in 2021

Conclusion

As can be seen, CTCI is committed to building a flexible supplier management system that advances through time, so that it can expand its sustainable influence. In response to the trend of net zero transformation, CTCI has joined "Taiwan Net Zero Action Alliance" and supports the " Science Based Targets initiative" (SBTi) campaign. CTCI has promised to set a carbon reduction schedule based on the 1.5°C target. In 2022, CTCI has formulated the "Improvement Actions on Sustainability and Net Zero Supply Chain Management." Under the new scheme, there will be management tactics such as signing letter of commitment to net zero emissions; sustainability survey; and auditing suppliers’ emissions. With carrot and sticks, suppliers will be requested— in phases and based on the level they are at— to provide their emissions data and make an emissions reduction commitment beginning in 2023. On the one hand, this strengthens CTCI’s supplier assessment and management capabilities; on the other hand, this helps CTCI gradually meet the goal of reducing its Scope 3 emissions. That way, CTCI expects more suppliers to join and support the climate cause, and jointly create a sustainable and resilient value chain.