Eco-friendly Innovation

綠色創新

Establishing "Green Engineering Projects" to Guard the Earth's Sustainability

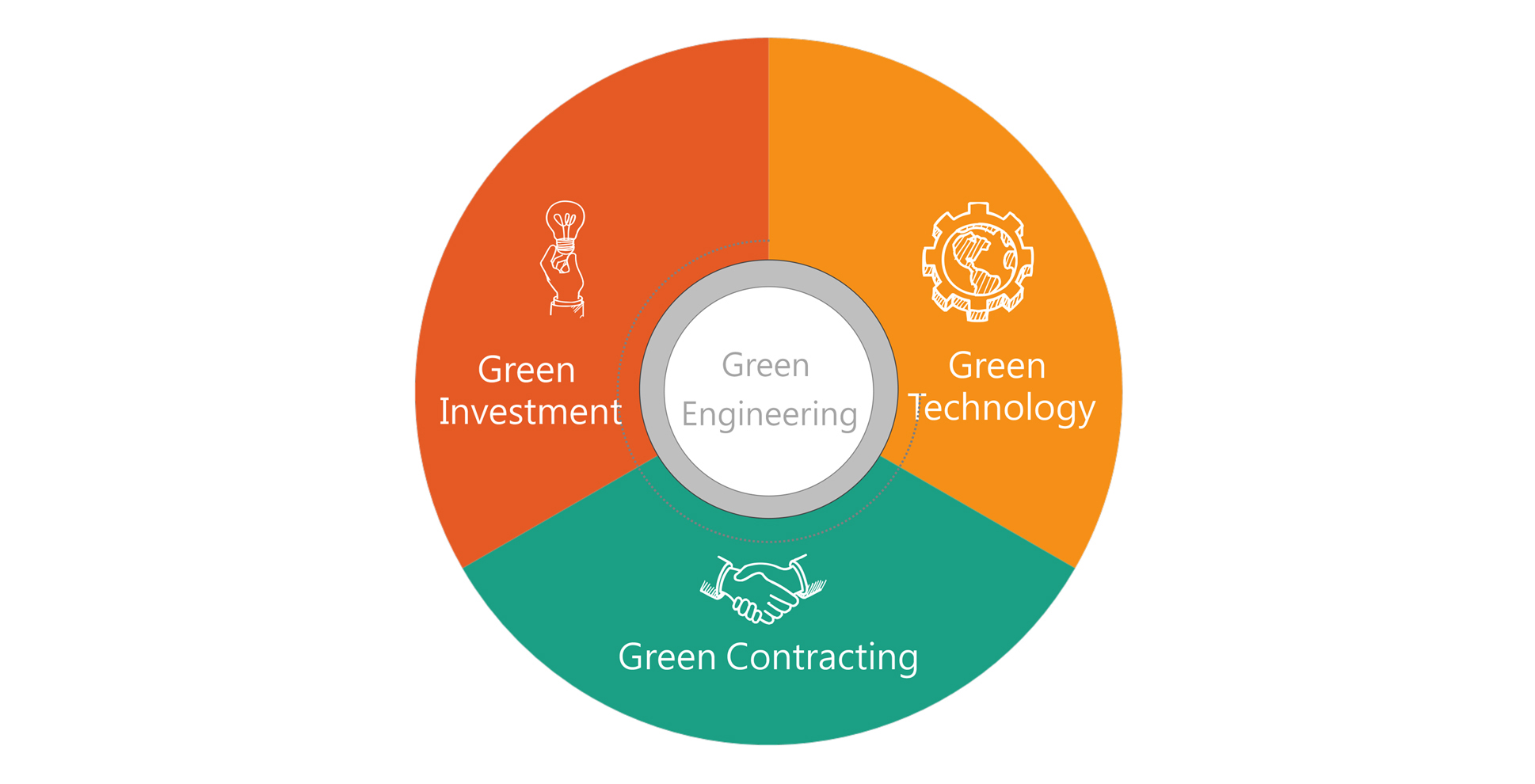

Adhering to the concept of “Leading Net Zero EPC through ESG Engagement of All Members,” CTCI has long been dedicated to sustainability with its core business. Through the promotion of "Green Engineering" in expanding green business opportunities, we not only achieve remarkable performance in low-carbon and environmental protection related engineering fields, but also help the owners to achieve the goals of energy saving, carbon reduction and cost saving, resulting in a win-win situation for the economy and the environment through engineering expertise. In this article, we will briefly introduce the three aspects of "Green Engineering": Green Technology, Green Investment, and Green Contracting.

Three aspects of Green Engineering.

Green Technology: Introducing Carbon Reduction Technologies to Reduce Environmental Impact

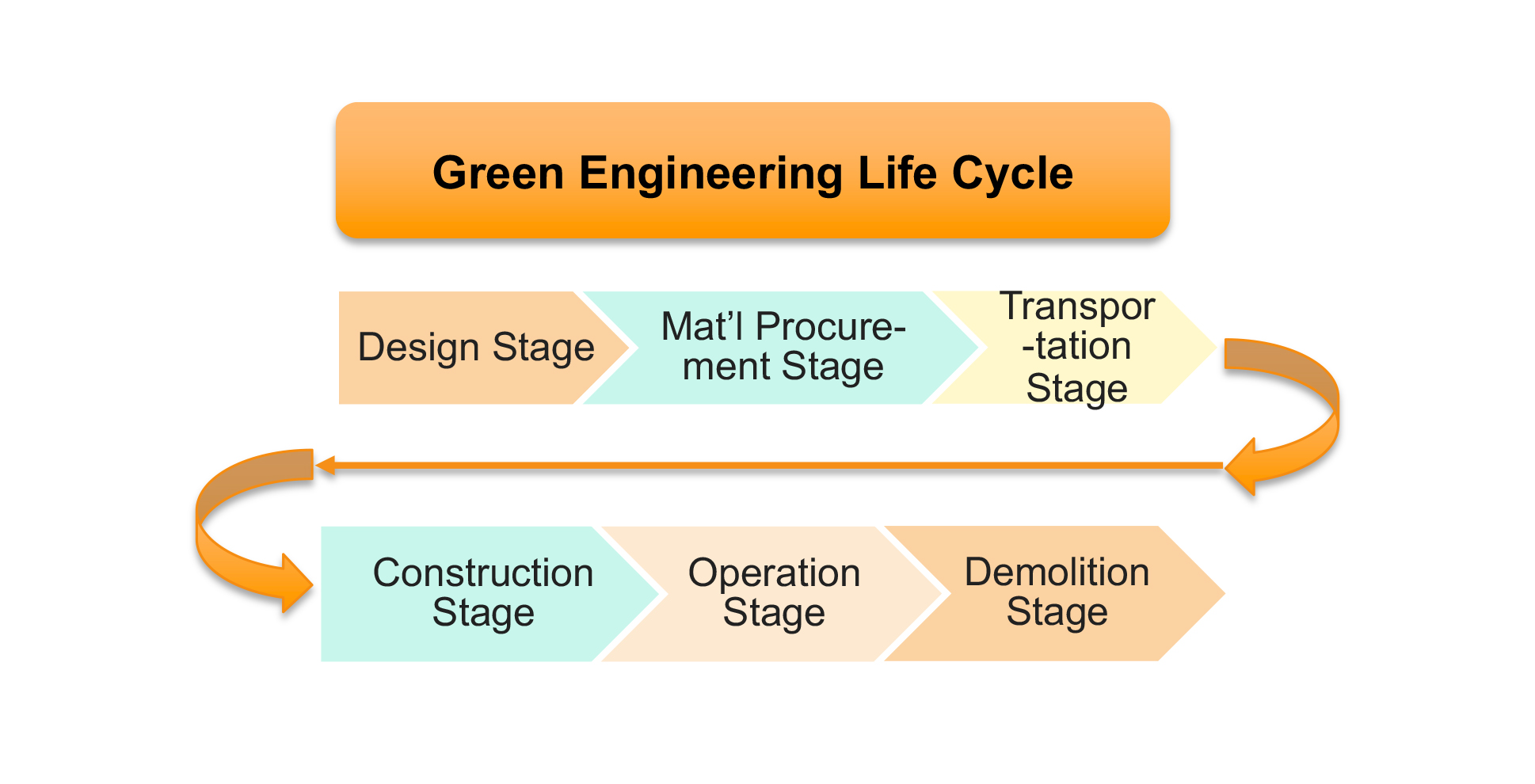

CTCI provides owners with innovative engineering technologies for delivering "Net Zero EPC Projects," and is committed to reducing environmental impact by actively introducing green technologies into the whole life cycle of project executions. Starting from the engineering design stage, we take into considerations state-of-the-art carbon reduction technology, adopt green procurement strategies in the procurement and transportation stages, and utilize green construction methodologies in the construction stage, so that the emission reduction benefits may be enhanced. The application of these green technologies not only contribute to cost reduction, but also extends the emission reduction benefits to our clients in operation and even the demolition stage. Examples for the enhanced performance from 2021 are demonstrated below: 1. Design stage: Use the best available green technologies in designs to mitigate environmental risks; actions taken include optimizing process for energy saving, water saving, green building, air pollution control, and value engineering. 2. Material procurement stage: Use ecofriendly, renewable and recycled materials. 3. Transportation stage: Reduce transportation costs and transportation emissions through local procurement. 4. Construction stage: Develop automation technologies to reduce the on-site workload, and take energy-saving, water-saving and waste reduction measures to reduce construction carbon emissions. 5. Operation stage: Adopt green technologies and high-efficiency equipment to save an estimated 2,383 MWH per year of electricity at the owner's operation stage. In 2021, the low emission valves applied in the design stage has been estimated to reduce VOCs (Volatile Organic Compounds) emissions by 138.06 metric tons per year at the plant operation stage for our client. 6. Demolition stage: Classify properly the construction waste, and deliver the combustible waste to the waste incineration plants in Taiwan operated by ECOVE, subsidiary of CTCI.

Green engineering life cycle.

Green Contracting: Low-carbon Environmental Contracts Help Achieve Remarkable Business Growth

CTCI actively grasps net-zero and low-carbon business opportunities, and has achieved excellent operating results. The low-carbon and environmental projects undertaken by the Group in 2021, such as construction of Taiwan Cement Corporation’s DAKA Renewable Resources Center, and the biodiesel plant EPC project in USA, are valuable to global sustainability. From 2015 to 2021, the backlog of contract has grown by 450%, making low-carbon environmental projects an important driving force for business growth. The following are significant features of the Group's "green contracts" over the last few years: 1. Innovation and R&D: We put in around 50% of the R&D investment each year (over 70 million TWD in 2021) focusing on environmental technologies, including iEPC (intelligent EPC), net-zero EPC technologies, and digital twin. 2. Step into the high-tech field: We set up ATFBO (Advanced Technology Facilities Business Operations) to integrate the Group's domestic and abroad resources and take advantage of Taiwan's existing strength in omnibearing planning/design service, plant construction, clean room, etc., as well as CTCI's global bases to systematically seize business opportunities in the field of high-tech facility engineering . 3. Technological research: We establish the New Business Development & Strategy Management Committee to seek business opportunities in carbon reduction/net-zero technologies and investment projects, and cooperate with clients and the Industrial Technology Research Institute (ITRI) on hydrogen energy, energy storage, carbon capture, utilization and storage (CCUS) and other technical cooperation and business development. In addition, CTCI also served as the convener of the carbon capture task force of the Taiwan-U.S. Carbon Capture, Utilization and Storage (CCUS) Industry Promotion Alliance, and signed cooperation agreements for the development, verification and application of the latest technologies.

Green Investment: Active Deployment in Resource Cycling Industries

The meaning of “green investment” is to undertake projects in areas of incineration and electromechanical maintenance, recycling and reuse, and renewable energy in the form of BOO and BOT. CTCI has made diverse green investments in recent years. In the field of incineration plants, there are Taoyuan Biomass Center and Changping Industrial Park Resource Recycling Center; in solar photovoltaics, a total of about 130MW domestic and abroad capacity were developed by the end of 2021; as to water resource reclamation, there are TSMC Southern Taiwan Science Park Wastewater Reclamation Unit and Chungli Sewerage System in Taoyuan, etc. Through the above-mentioned green investments, the Group is dedicated to improving the efficiency of resource reuse to grasp business opportunities of circular economy. In 2021, the relevant performance and achievements of operations in incineration and electromechanical maintenance, recycling and reuse, and renewable energy, three major areas of green investment, are as follows. 1. Incineration and electromechanical maintenance: The waste incineration plants generate 1.449 billion kWh of electricity, which can supply around 380,000 households in Taiwan with power usage for a year. 2. Recycling and reuse: The treatment capacity of sewage reaches 27.9 million metric tons, and that of waste solvent (waste IPA) is up to 11,100 tons. 3. Renewable energy: The solar photovoltaic power plants generate 94.77 million kWh of electricity, which can supply around 25,000 households in Taiwan with power usage for a year.

CTCI’s green investment in various fields.

Conclusion

Envisioning to be "The Guardian of Sustainable Earth," CTCI is devoted to elevating engineering business to an ESG business with the most advanced "Green Engineering" technologies, to help customers achieving the goal of net zero emissions, and make concrete contributions to global sustainability.