Eco-friendly Innovation

綠色創新

Implementation of Fixed Shockwave Ash-Cleaning Technology—Gangshan Energy Resource Center Achieves High-Efficiency Carbon Reduction Transformation

To achieve the 2050 net-zero emissions target, ECOVE, a subsidiary of the CTCI Group, upholds the core value of "Every Resource Counts" and actively promotes energy conservation and carbon reduction initiatives. This article uses the operationally managed "Gangshan Waste Resource Recovery (Incineration) Plant in Kaohsiung City" (hereinafter referred to as Gangshan Plant) as a case study to demonstrate how the implementation of fixed shockwave ash-cleaning equipment not only effectively enhances incineration processing and power generation efficiency, but also contributes to energy optimization, further achieving energy conservation and carbon reduction goals.

Introduction to Shockwave Ash-Cleaning Technology

The shock pulse generator (SPG) employs non-contact ash-cleaning technology that utilizes compressed air mixed with fuel gas for ignition, instantaneously releasing high-pressure shock waves that penetrate flue ducts or boiler interiors to loosen and dislodge ash deposits, clearing internal equipment buildup. Compared to traditional steam blowing or mechanical percussion techniques, shockwave ash-cleaning technology offers superior cleaning power and is suitable for high-temperature environments. It features advantages such as no mechanical wear and low maintenance requirements, making this technology widely applicable in high-temperature flue areas including incinerators, waste heat boilers, and selective catalytic reduction (SCR) systems. Although initial investment is relatively high and requires coordinated safety explosion-proof design, its benefits in improving heat exchange efficiency, reducing pressure losses, and extending operating time have gradually made it the preferred energy-saving solution for major incineration and energy plants. Shockwave ash-cleaning systems are categorized into mobile and fixed types, based on their application methods, as described below: .Mobile shockwave ash-cleaning: Operators use specialized containers to introduce fuel gas into designated furnace areas for detonation to generate shock waves, targeting different areas for soot removal and reducing cleaning dead zones. However, during execution, considerations must be given to cold air infiltration and ash discharge system load limitations. If the amount of dislodged ash exceeds capacity, it may cause ash bridging in the discharge system, potentially leading to furnace shutdown risks. In such cases, manual cleaning through manholes may be necessary, making operator safety a critical consideration in risk assessment . .Fixed shockwave ash-cleaning: This system mixes compressed air with small amounts of fuel gas for ignition, forming high-pressure expanding gas masses that generate powerful shock waves. These shock waves are transmitted through specially designed nozzles or waveguides to target areas, vibrating flue walls or heated tube bundles to dislodge attached dust or fouling layers, which then naturally fall into ash hoppers or collection systems under gravity. The system can be programmed through programmable logic controllers (PLC) for periodic shock wave cycles, automatically controlling ash accumulation levels, effectively reducing ash bridging risks and minimizing manual cleaning and unplanned shutdowns.

Implementation of Fixed Shockwave Ash-Cleaning to Enhance Incinerator Performance

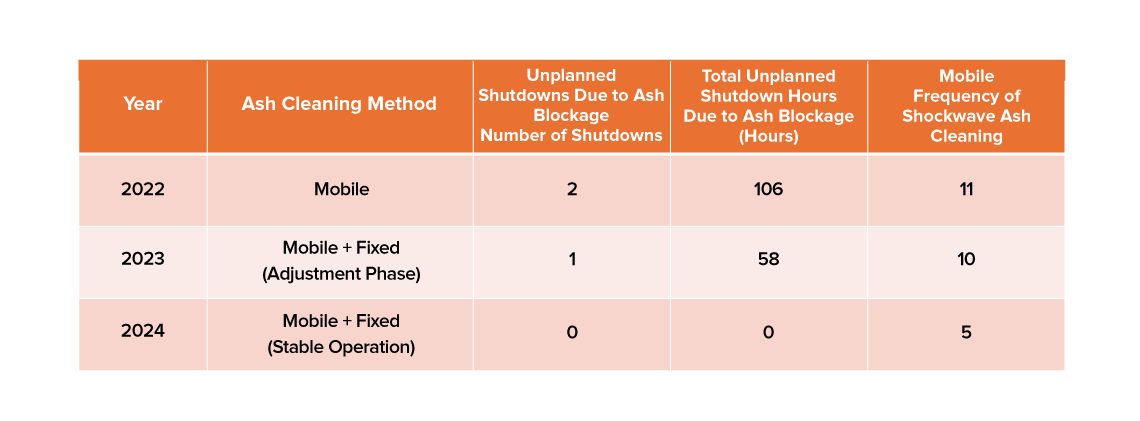

Prior to 2023, Gangshan Plant primarily relied on mobile shockwave ash-cleaning systems. In 2022, for example, 11 cleaning operations were performed throughout the year, yet 2 unplanned shutdowns still occurred due to ash blockages, accumulating 106 hours of downtime. To improve this situation, the plant began testing fixed shockwave ash-cleaning systems in 2023 and achieved stable operation in 2024. Following implementation, unplanned shutdown incidents were reduced to zero, and mobile cleaning operations were halved to only 5 times, required only for dead zones not covered by the fixed system. Shockwave ash-cleaning technology helps maintain clean conditions of heat exchange equipment and combustion spaces within incinerators, suppressing thermal efficiency losses and thereby improving overall thermal conversion efficiency and combustion stability. Under long-term continuous operation conditions, it effectively prevents efficiency degradation and unplanned shutdowns caused by ash accumulation, strengthening system continuous operation capability. The following table summarizes changes in unplanned shutdown incidents and shock wave cleaning frequency caused by ash blockages from 2022 to 2024. Data shows that since implementing fixed shockwave ash-cleaning, equipment failures have been effectively reduced while cleaning efficiency has improved.

Gangshan Plant Unplanned Shutdown and Mobile shockwave ash-cleaning Statistics

Fixed Shockwave Ash-Cleaning systems installed on the second flue (upstream) and the third flue (downstream)

Reducing Carbon Equivalent Emissions and Improving Operational Efficiency

Since Gangshan Plant implemented fixed shockwave ash-cleaning technology and achieved stable operation in 2024, annual operating time increased by 106 hours compared to 2022. Based on a single furnace design processing capacity of 450 metric tons per day, this represents an increase of approximately 1,988 metric tons in waste incineration processing capacity and an additional 855 MWh of power generation. Simultaneously, unplanned shutdowns decreased by 2 incidents compared to 2022, demonstrating the positive contribution of equipment improvements to energy recovery benefits. Converting to carbon emission benefits, based on the 2024 announced electricity carbon emission factor (0.474 kg CO₂e/kWh), the increased power generation is equivalent to reducing approximately 406 metric tons of carbon dioxide equivalent emissions. Due to reduced unplanned shutdowns, diesel consumption also decreased accordingly. Using the diesel carbon emission factor (3.29 kg CO₂e/liter), the diesel savings are equivalent to reducing approximately 4.4 metric tons of carbon dioxide equivalent emissions. Using Da'an Forest Park's annual carbon absorption capacity of approximately 387 metric tons of carbon dioxide as a benchmark, this is equivalent to 1.05 Da'an Forest Parks' carbon absorption for an entire year, concretely demonstrating this technology's positive environmental impact. Fixed shockwave ash-cleaning technology represents an innovative solution targeting carbon deposits and dust accumulation on incinerator heat exchanger surfaces. Through precise control of shock wave frequency and intensity, it effectively maintains heat transfer efficiency within furnace interiors, reduces unplanned shutdowns and cleaning time, while extending equipment service life, achieving dual improvements in environmental benefits and operational efficiency.

Conclusion

Net-zero carbon emissions have become the core objective of global sustainability policies. Under this trend, implementing high-efficiency energy-saving technologies in existing facilities has become key to energy resource center operations and transformation. ECOVE's implementation of fixed shockwave ash-cleaning technology not only effectively improves equipment operating efficiency and power generation benefits, but also significantly reduces unplanned shutdowns and carbon emissions, demonstrating the potential for traditional waste treatment facilities to achieve low-carbon operations. As technology optimization and application scale expand, the benefits of carbon reduction and resource circulation will continue to grow. This technology plays a crucial role in advancing waste treatment systems toward sustainability, contributing to the localization of environmental technologies and carbon neutrality goals, further guiding industries toward high-efficiency, low-carbon sustainable development pathways.