Eco-friendly Innovation

綠色創新

Keeping the Earth Sustainable by Constructing Zhongli Water Resources Recovery Center

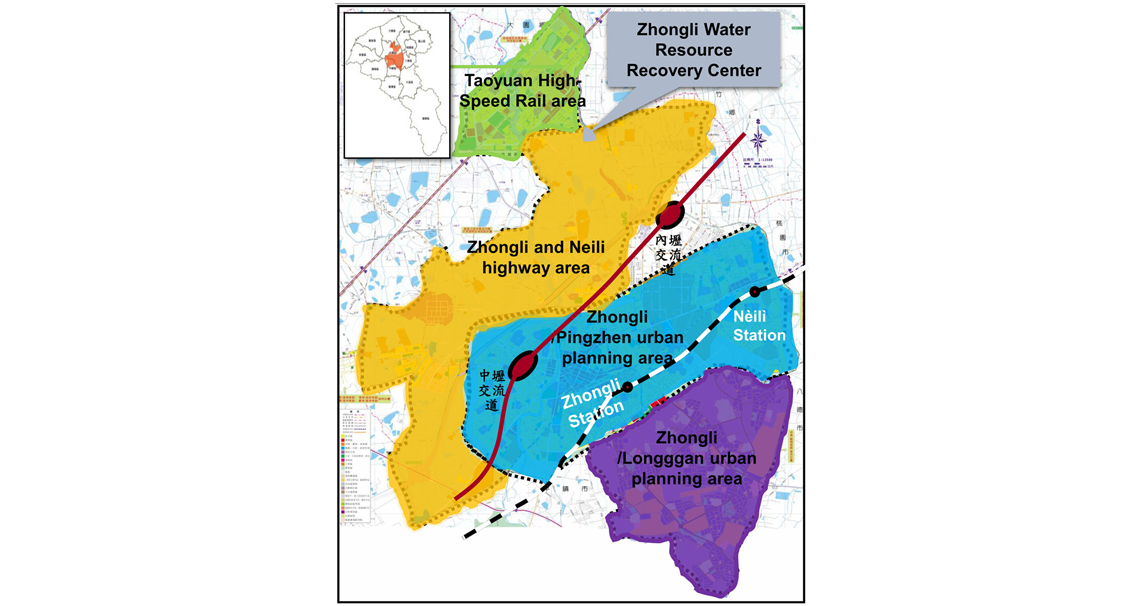

To prevent water pollution from the direct discharge of wastewater into Xinjie Creek, a local creek in Zhongli, the Taoyuan City Government has launched the Build-Operate-Transfer (BOT) Project for the Construction and Operation of the Zhongli District Sewerage in Taoyuan City (hereinafter referred to as “the Project”) via the Promotion of Private Participation, offering a concession period of 35 years. Having formed a joint venture and successfully securing the contract, CTCI and Hsin-Dar Environmental Corporation (HDEC) subsequently established a company called CTCI-HDEC Water Business Co., which is responsible for the Project’s construction and operation. This project represents one of the most socially beneficial and large-scale domestic public infrastructure in recent years, and is the second-largest BOT project in Taoyuan. The construction scope includes building a water resource recovery center and a sewer pipe network stretching 246 kilometers, which will be capable of treating approximately 200,000 households’ domestic sewage in Taoyuan and reaching the goal of sewer pipe network connection for 32% of the city’s households. The project will significantly improve creek water quality and enhance the overall living environment in Taoyuan City. The water resource recovery center, or officially named Zhongli Water Resource Recovery Center (Zhongli WRRC), is being constructed in four phases, with each phase designed to treat 39,200 tons of sewage. The center, which became operational since January 2025 and has begun treating sewage, will gradually expand in conjunction with the construction progress of the sewer pipe network. It is expected that the entire sewer network will be completed by 2040, reaching a daily sewage treatment capacity of 156,800 tons. Geographically, the Project covers four areas, including the Taoyuan High-Speed Rail area, Zhongli and Neili highway area, and the two urban planning areas of Zhongli/Pingzhen and Zhongli/Longgang, spanning approximately 6,017 hectares in total.

The geographical scope of this project

Community-Friendly Construction Process for Sewer Network and Sewage Pipe Connection

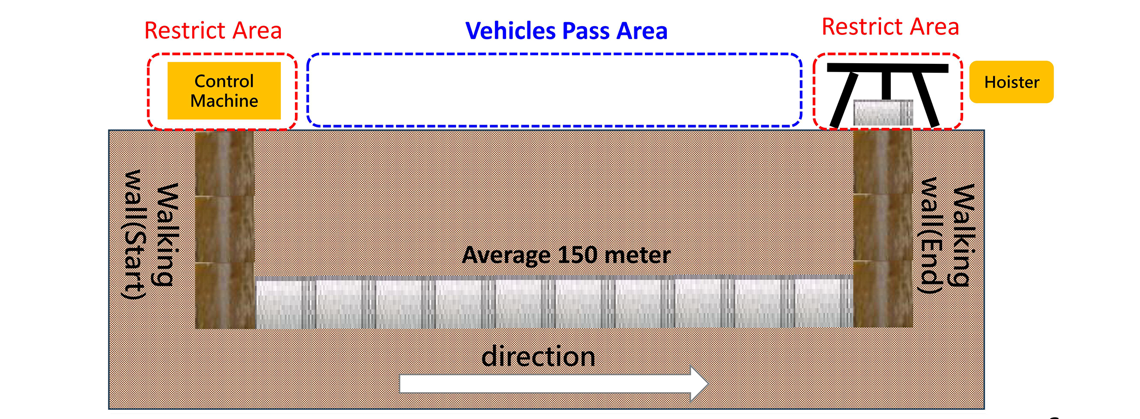

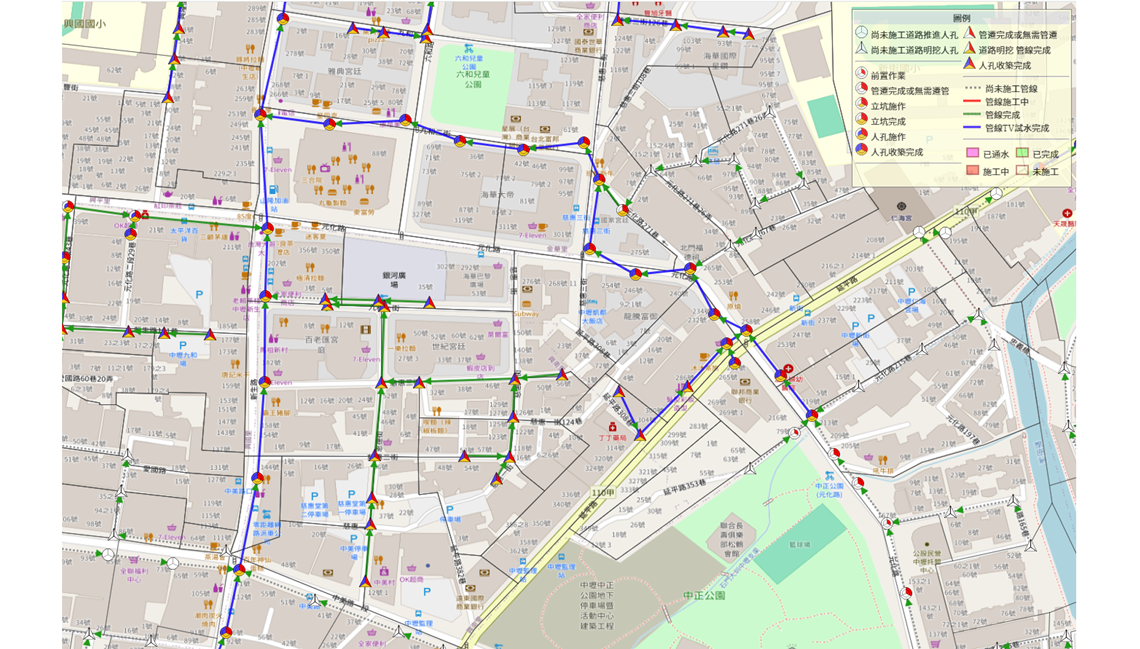

As of the end of February 2025, approximately 23 kilometers of sewer network has been completed, with about 6,000 households connected to the sewage pipes. The project is now moving towards the city center of Zhongli. To minimize the impact on road traffic, construction of the sewer network follows the pipe jacking method. Two shafts, each measuring 3m in diameter, are installed at the upstream and downstream ends of every underground sewer pipe. This approach allows vehicles to pass through the area above ground between the two shafts. One of the sites was personally visited by Taoyuan City Mayor San-cheng Chang in April 2023, who did a pipe tour and praised the excellent construction and safety quality. To manage the 19-year construction period of this project, CTCI-HDEC has established a GIS management system (https://pub.wgi.tw/) to monitor the status of the sewer segments that are either completed, ongoing, or pending. The system uses an intuitive map legend concept, making it easy for the public to get real-time updates.

Taoyuan City Mayor San-cheng Chang inspected a 6m-deep underground pipe.

Pipe jacking method for sewer construction

GIS system established by CTCI-HDEC

Regarding sewage pipe connections, older buildings often have mixed drainage systems where wastewater is discharged together with rainwater collected from the roof. In the past, during construction, there were frequent incidents of rainwater pipes being mistakenly connected to the sewage system, which led to overloading of the sewers and the water resource recovery center during rainy days. To resolve this issue, CTCI-HDEC made detailed investigations during their studies on the discharge outlets to get a full picture of the connection of rainwater pipes with sewage system. First, the team visually inspected the pipes to determine if rainwater pipes were mistakenly connected to sewage pipes. Based on their study, they then determined if connection to sewage pipes could be designed. If visual check proved difficult, the team inquired the residents for detailed information instead. On sunny days, the team could also check if moisture, dirt, or odor was present at the discharge point to determine whether the pipes were improperly connected.

A Potentially Certified Venue for Environmental Education that Combines Green Energy and Smart Features

Located in Qingpu, the Zhongli WRRC fuses concepts of green building and smart building, incorporating gold-level green architecture and silver-level smart building designs. Its exterior design is inspired by the traditional rural Sanheyuan architecture and includes water park elements, such as an ecological stormwater detention pond and rooftop greening, transforming it into a recreational area. With plans to acquire certification for the WRRC as an environmental education venue, CTCI-HDEC wishes to change the public's negative perception of sewage treatment facilities and to create greater educational value. The center builds upon the concept of "Three Circles and One Main Axis," referring to water circulation, green circulation, and human circulation. This is a concept that seeks to bring about a beautiful, interesting, relaxing, and educational space that helps residents and visitors appreciate the value of water resources and the operation of sewage treatment systems. Additionally, to blend in with the community, a 20-meter green belt surrounds the peripheral of the WRRC, which keeps trees intact while setting up pedestrian pathways that are connected to the nearby bicycle route network, forming a circular flow. This design allows residents and visitors to be able to enjoy for exercise or leisure.

Zhongli Water Resource Recovery Center

A management center certified as gold-level green architecture and silver-level smart building.

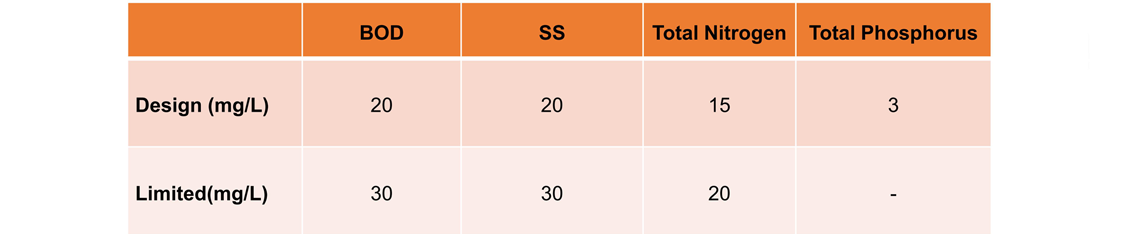

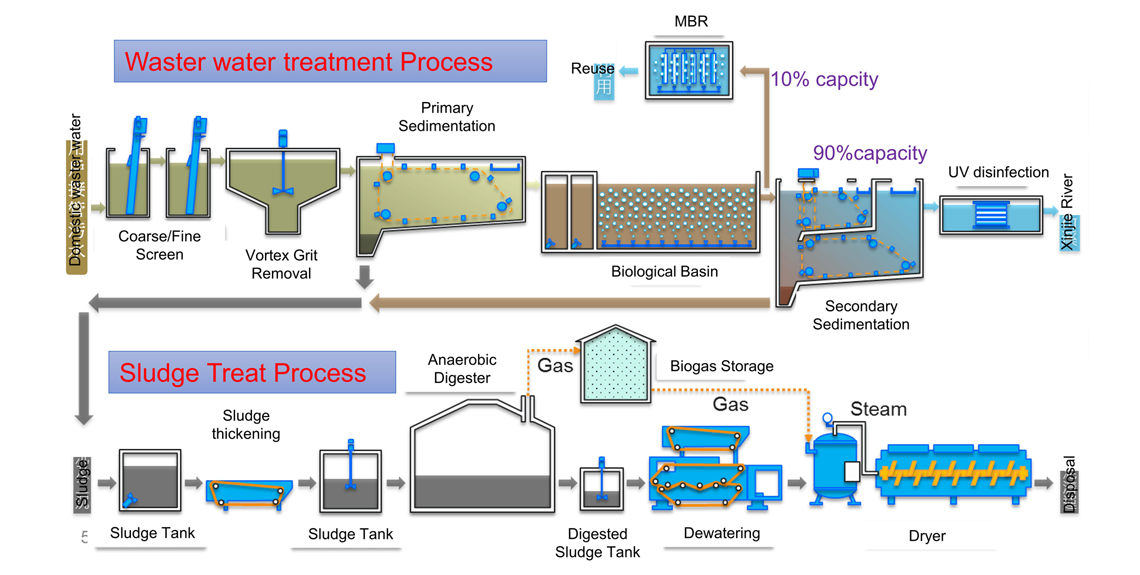

Breathe New Life into Zhongli’s Xinjie Creek, Water Reclamation Project in Development

The Xinjie Creek flows through downtown Zhongli and Pingzhen, and along with the Laojie Creek, it is one of the two major creeks in Zhongli. The Zhongli WRRC adopts Modified Ludzack-Ettinger(MLE), a type of nitrogen removal and chemical phosphorus removal process, in its design. The quality of the treated effluent far exceeds the standards stipulated by environmental regulations. In addition to alleviating the pollution load on the Xinjie Creek, the treated effluent can be used for road cleaning applications, thereby reducing the demand for potable water. Ten percent of the water is treated with the MBR (Membrane Bioreactor) process, which not only serves as recycled water for the plant but can also be used for industrial-grade water reclamation process in emergency. In continuation of this project, the Taoyuan City Government has decided to optimally recover water resources and support industrial zones with a stable water supply. Therefore, it has unveiled a project to establish the Zhongli Water Reclamation Plant, which has been approved by the Executive Yuan. This water reclamation project will further optimize the treated effluent from the Zhongli WRRC to meet quality standards for reclaimed water. The project will produce 88,000 tons of reclaim water per day, with construction planned in four phases. The first phase is expected to produce 22,000 tons of reclaim water daily, which will supply industrial water to the Zhongli, Dayuan, Yangmei, and Pingzhen industrial zones, meeting the demand for industrial water.

Design effluent quality for Zhongli Water Resource Recovery Center

Wastewater Treatment with Biogas Energy Recovery Benefits

The wastewater treatment process can be divided into two main stages: water treatment and sludge treatment. The sludge undergoes four steps—concentration, digestion, dewatering, and drying—to gradually reduce its water content. The biogas produced during the digestion process is purified and can be used as a boiler heat source, replacing natural gas. The steam or hot water generated by the boiler can be used for sludge drying and to maintain the temperature of the anaerobic digestion tanks. The amount of biogas produced in this project is equivalent to 8.8 million kWh of electricity, which effectively reduces the sludge’s water content from 80% to 40%, improving the sludge dewatering efficiency and reducing the number of trucks needed for sludge disposal. This, in turn, lowers carbon emissions and supports the achievement of a circular economy. The digestion process adopts anaerobic treatment and will be built in two phases. The first phase is expected to start in September 2025, while the second phase will begin in September 2035. The reason behind such two-phased construction is to consider of the growth of wastewater quantity, as it would only become economically viable when the daily wastewater volume exceeds 20,000 tons. This would prevent overinvestment and equipment idleness.

Overall process for waste water treatment

CTCI has been deeply involved in the water resources business for over 40 years, actively seeking global opportunities in water recycling and expanding its range of services. In addition to the sewer construction service as well as the plant construction service for the recovery of municipal wastewater and industrial effluent seen in this project, CTCI plays a role in the electronics industry by helping reclaim industrial wastewater for reuse in the semiconductor manufacturing processes. With a commitment to delivering the most reliable engineering services by integrating green engineering, recovery technologies, and water-related expertise, CTCI will continue to partner with global clients to fulfill its ESG vision of becoming a Guardian of Sustainable Earth.

.jpg)