Eco-friendly Innovation

綠色創新

Environmental Protection Issues Related to Excavation and Pumping in Turnkey Projects

In construction projects, dewatering operations are essential during excavation when the groundwater level is higher than the excavation bottom. In general alluvium, dewatering is often overlooked due to relatively lower permeability coefficient. Many construction managers tend to include dewatering as a lump-sum item in the contract, which is awarded at a fixed price, without proper consideration on whether such price is sufficient for installing adequate number of dewatering wells and pumps. Furthermore, sine the electricity cost for dewatering is usually borne by the main contractor, construction managers rarely delve into how much money is spent on electricity in dewatering operations. In other words, when adopting lump-sum contracting model, failing to consider electricity costs and the configuration of dewatering wells, such as the layout and the depth of the pumps, would cause significant problems. To minimize costs and effort, dewatering contractors often increase the spacing between dewatering wells and tend to over-extract water. These can lead to water levels or water pressures in the excavation area that are inconsistent with the assumptions made in the original retaining wall design. Even if they have been accounted for as E&C (escalation & contingency) factors by the construction manager, a thorough consideration is nevertheless difficult, leading to potential damage to adjacent areas and subsequent disputes. As an affiliated company of CTCI Group, which is a leading engineering, procurement, and construction services provider in Taiwan and among one of the top 100 globally, CTCI Resources Engineering Inc. (CTCI REI) has extensive experience in addressing these issues. Specific approaches include: .During the bidding phase, CTCI REI is capable of quantifying and incorporating these concerns into the bid estimation to reduce risks. .During the excavation phase, CTCI REI can effectively manage dewatering operations, efficiently utilize water resources, and keep its commitment to balancing environmental protection and economic development needs. In the following sections, we will share about CTCI REI’s experience from the execution of a project in Pingtung, southern Taiwan.

Site Conditions and Design Outcome

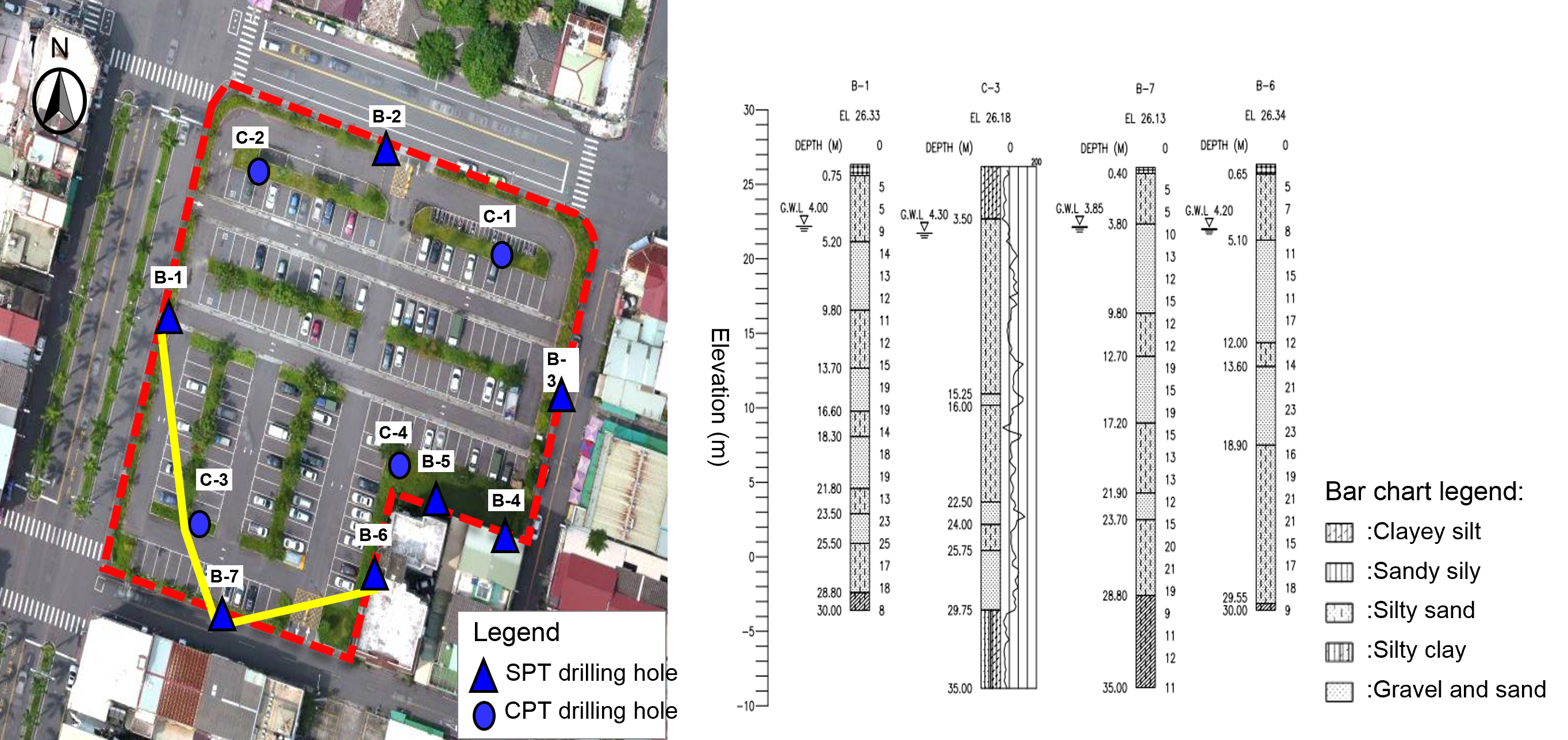

The project discussed here is located in the urban area of Pingtung City. To the southeast, there are six-story apartment buildings and four-story townhouses next to the site, while the other sides are bordered by roads. As shown in the figure below, to the west and south, across the roads, there are 3 to 4-story attached townhouses. To the north, across a road, is a cultural and creative park, and to the east, across an alley, there is a market. Based on the drilling results, the geological conditions reveal that the strata within the first 30 meters below the surface consist of gravelly sand, while from 30 to 35 meters, there is an impermeable clay layer.

Site environment overview, borehole configuration, and stratigraphic profile.

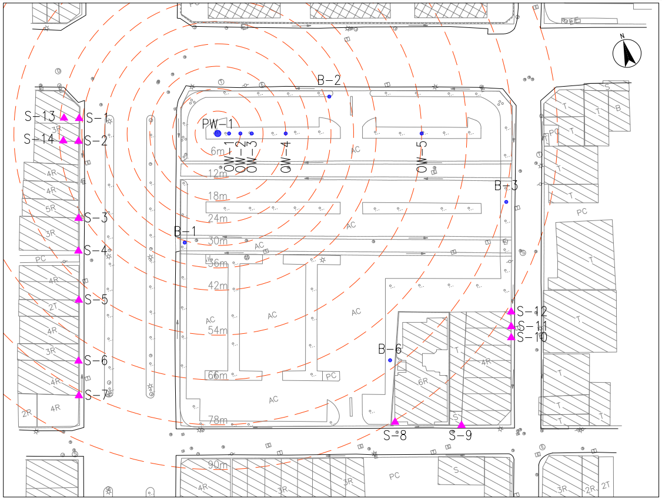

Due to the sandy gravel strata, conducting constant or falling-head permeability tests is not considered highly reliable. To ensure precise calculation of the dewatering operation during excavation, the REI team performed on-site pumping tests to obtain the permeability coefficient. The dewatering test wells on the site included five newly installed observation wells, in addition to the water-level observation wells from the original geological drilling, totaling nine observation wells, as shown below. After 36 hours of pumping, the permeability coefficient was determined to be 2.68*10⁻³ m/sec.

Dewatering test wells and observation well configuration.

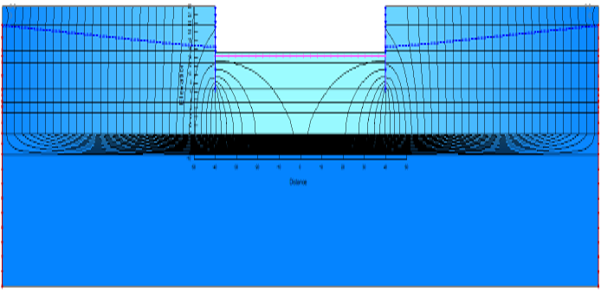

The excavation at the site adopted a continuous wall method with horizontal bracing. Initially, the continuous wall depth was planned to be 20 meters. However, after analyzing data such as the dewatering drawdown and other factors, it was estimated that the maximum settlement of adjacent buildings would not meet the protection requirements. Additionally, 80 dewatering wells would be required, with an installation cost of NT$5.2 million and an estimated electricity cost of at least NT$11.24 million, bringing the total to NT$16.44 million. This approach would also cause damage to adjacent buildings, so it is required to introduce building protective measures, adding further costs.

Dewatering drawdown curve

In this project, to minimize settlement outside the excavation area due to dewatering, CTCI REI team increased the depth of the continuous wall to 32 meters to penetrate the impermeable clay layer, deeper than the original design. When doing the actual reinforcement design, the section below 20 meters mainly serves as a waterproofing function, using only the minimum amount of reinforcement. With these adjustments, the dewatering drawdown curve did not significantly affect the excavation area. In terms of costs, deepening the continuous wall to the impermeable clay layer would result in a construction cost of approximately NT$9.45 million, with an additional NT$9.52 million for reinforced concrete materials, totaling NT$18.97 million. The electricity cost would be significantly reduced to NT$558,000, bringing the total to NT$19.53 million. Although this solution initially seems more expensive than the original plan, the original proposal did not account for the costs of building protection, dewatering treatment, or additional wells, making the actual expenditure higher. Additionally, considering sustainability, the original plan required pumping several thousand tons of water daily, which is not in line with environmental protection principles. Based on these factors, the new plan is clearly more cost-effective and sustainable.

On-site Construction Control and Monitoring Results

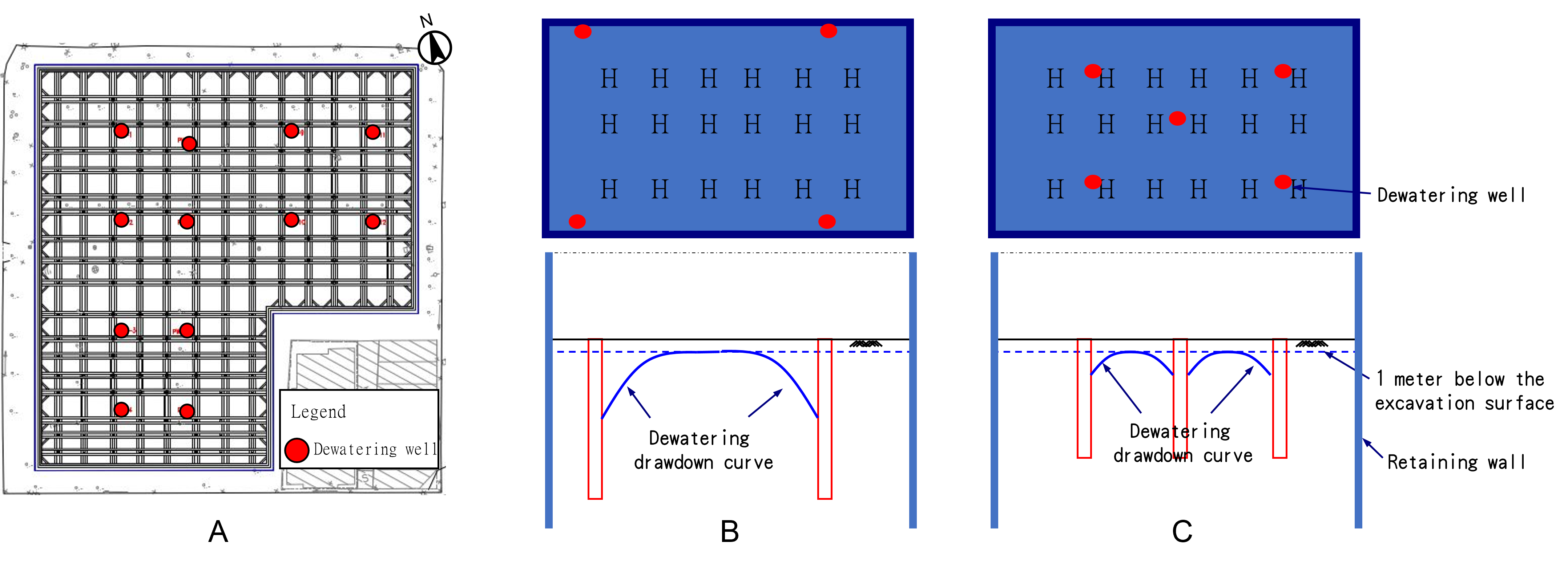

During the actual construction, no dewatering wells were installed outside the excavation area. Inside the excavation area, 12 dewatering wells were evenly distributed, which are marked in red in Figure A below. This arrangement minimized the impact of the dewatering drawdown curve (as shown in Figure C). If the spacing of the dewatering wells were increased, it would result in the situation shown in Figure B, with a larger impact and inconsistent water pressure compared to the original design assumptions. The dewatering depths were adjusted according to the excavation depths in each stage, with the appropriate wells being activated. Upon completion of excavation and cessation of dewatering operations, groundwater levels outside the excavation area remained unchanged, and the settlement of structures was less than 5mm. Dewatering was well-controlled, and no excessive drawdown occurred outside the site after stopping dewatering.

Actual dewatering well configuration and drawdown curve diagram.

Conclusion

Based on the previous discussions, here are the key takeaways: 1.Dewatering operations should not be handled as a lump-sum item in contracts. If left to the discretion of the dewatering contractor, this could severely affect the assumed data used in excavation support calculations and potentially cause damage to adjacent properties, as well as incur substantial electricity costs. 2.Typically, the groundwater extracted during excavation is discharged into the regional drainage system, and cannot be reintroduced into the soil. The replenishment of groundwater relies solely on rainfall, which is a slow process. In this case, in addition to controlling the volume of groundwater extracted to prevent over-extraction, CTCI REI team also considered installing recharge wells when large volumes of water were extracted, facilitating water resource recycling and achieving sustainable use. Looking forward, CTCI REI will continue to apply its extensive experience and accumulated monitoring data to similar projects, serving as a reference for adjacent building protection and enabling cost savings. This approach will help avoid waste of groundwater resources and achieve a win-win outcome for both economic development and environmental protection.