Sustainable Governance

永續治理

Combining Virtual and Reality: Innovative Applications of CTCI Digital Twin

As Industry 4.0 and digital transformation continue to reshape industries, modern enterprises increasingly rely on digital technologies. This is also true for EPC (Engineering, Procurement, and Construction) projects. As these projects become bigger in scale and more complex, however, traditional data management methods face significant limitations in keeping data accurate and complete—especially during the critical transition from construction to operational phases. These challenges can severely impact the sustainability and long-term performance of facilities.

Challenges in Data Handover and Solutions

Traditional project data management often depends on paper-based documentation or fragmented digital systems. When transitioning to the Operation and Maintenance (O&M) phase, incomplete or inaccurate data frequently hampers efficiency, escalates risks, and requires considerable time and resources for correction.

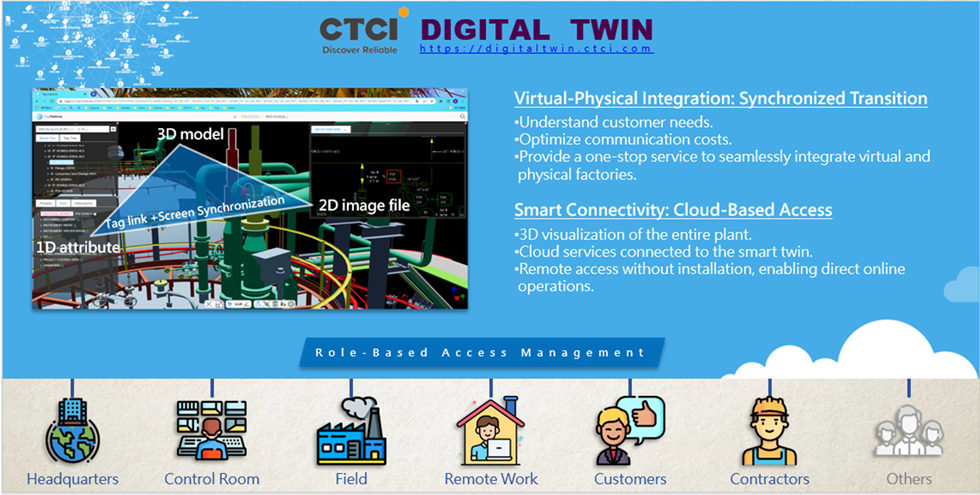

To address these challenges, CTCI has developed CTCI Digital Twin, an innovative solution that integrates data across all project phases into a unified digital platform. This seamless integration ensures continuous data updates, significantly enhancing operational efficiency and data accuracy.

Seamless Integration of EPC and O&M

CTCI Digital Twin bridges the data gap between EPC and O&M by digitizing essential design information, including equipment lists, pipeline schematics, instrument data, vendor documents, and operation manuals and incorporating it into a dynamic 3D model.

During the plant’s EPC phase, this real-time visualization capability enables project managers to monitor construction progress, ensure data integrity at every stage, and quickly assess project status. By providing a comprehensive digital framework, CTCI Digital Twin supports lifecycle management, empowering decision-makers to respond swiftly to risks and reduce uncertainties during construction and operation.

Dual Environmental and Economic Benefits

Technology-wise, CTCI Digital Twin is a leader in its field. Moreover, it delivers measurable environmental and economic benefits. By digitizing management processes, it eliminates paper waste, enabling fully paperless operations that align with sustainability goals.

The technology also optimizes workflows, reduces downtime, and lowers energy consumption, enabling plants to meet energy conservation and emission reduction targets. By predicting equipment failures and facilitating preventive maintenance, it minimizes disruptions and reduces costs, driving substantial economic returns and enhancing project profitability.

Cloud Technology Enhances Global Collaboration

Powered by Microsoft Azure, CTCI Digital Twin enables seamless global collaboration and efficient data management. Users can access up-to-date project data from anywhere without requiring additional software installation, ensuring flexibility and security in data sharing.

As businesses face growing global challenges, CTCI’s cloud technology breaks down geographical and time barriers, facilitating real-time synchronization of data between design teams at headquarters and on-site construction personnel. This boosts efficiency, enhances transparency, and allows teams to monitor progress and allocate resources seamlessly.

Moreover, CTCI’s cloud platform supports multi-location collaboration, which is essential for multinational corporations. Teams across different time zones and regions can communicate instantly, share data, and quickly resolve issues, avoiding delays caused by geographical constraints. This capability drives standardized practices, strengthens international competitiveness, and allows companies to operate more cohesively on a global scale.

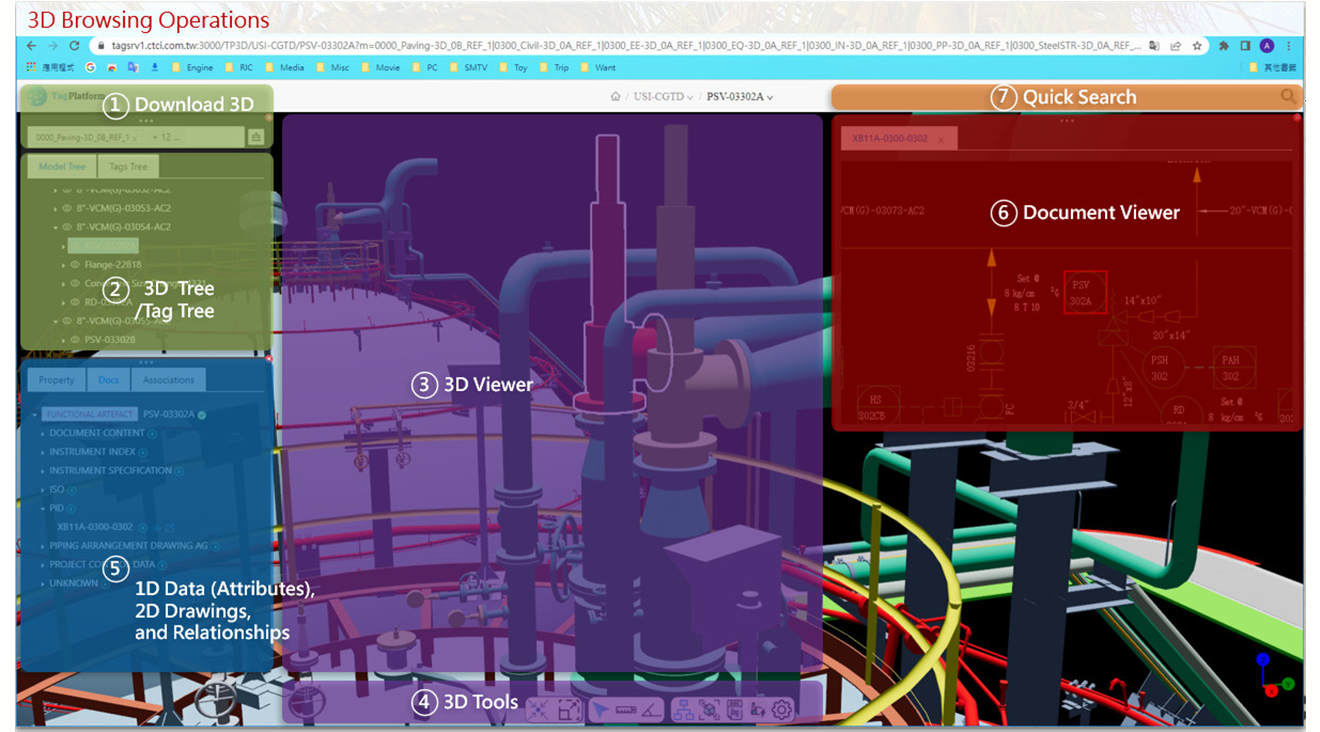

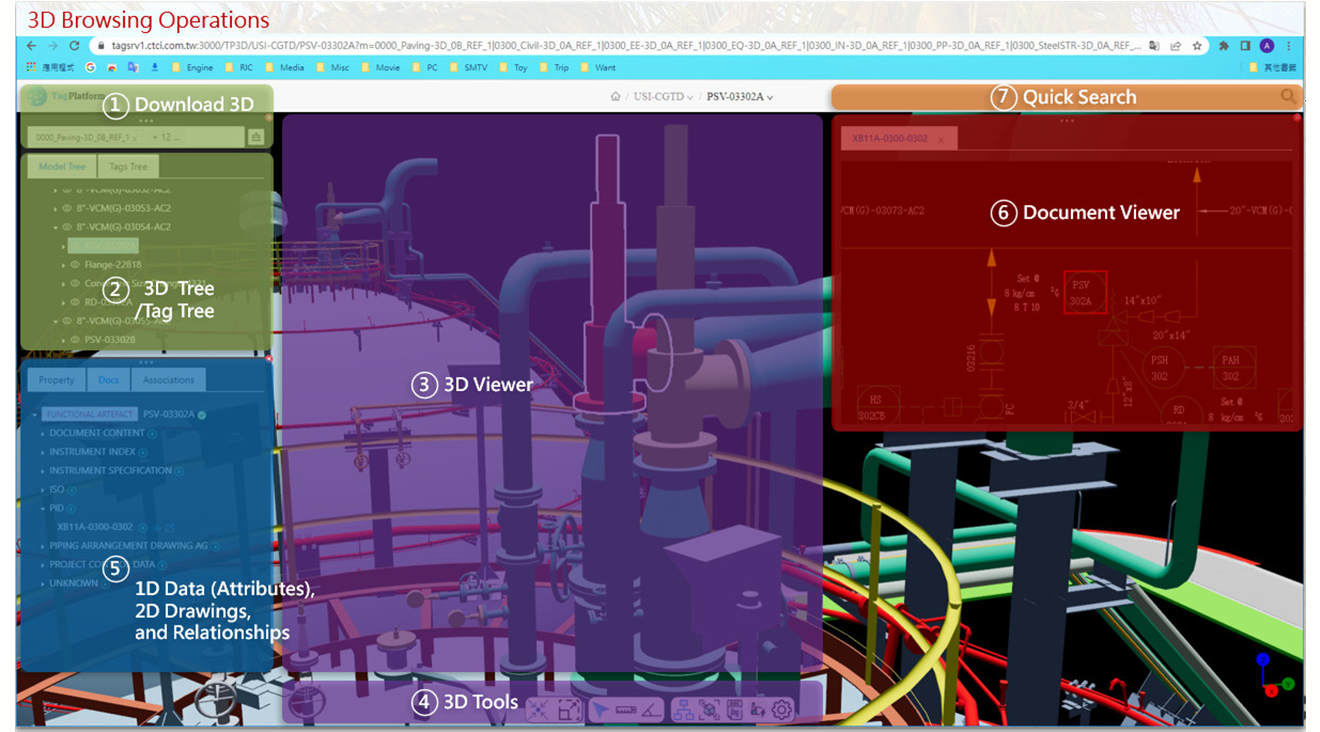

Intelligent Query and 3D Visualization

CTCI Digital Twin offers advanced intelligent query and 3D visualization features, revolutionizing data retrieval and management efficiency. Users can search for equipment statuses, operational records, and maintenance manuals using simple keyword inputs, much like Google search, streamlining navigation through extensive datasets. The intelligent query system also recommends relevant data based on user inputs, offering convenience and efficiency in data search.

Moreover, the 3D visualization interface provides a user-friendly virtual environment to examine equipment and facilities in detail. With the Tag Explorer feature, users can easily access comprehensive technical data and maintenance histories by clicking on specific equipment. This intuitive approach not only enhances data retrieval but also enables managers to simulate equipment performance, detect potential issues well in advance, and improve operational efficiency and maintenance accuracy.

Future Prospects: Innovations in Digital Transformation

As digital technology rapidly progresses, CTCI Digital Twin will become even more capable by leveraging AI and big data. In the near future, CTCI Digital Twin will deliver highly integrated, one-stop solutions for plant management and extend its applications to sectors like smart cities, energy management, and infrastructure development. By leveraging finer integration of data and intelligent predictive models, this technology will provide businesses with better insights for decision-making, allowing project management to become more efficient and precise.

With the accelerating pace of global digital transformation, CTCI Digital Twin is poised to play a pivotal role in the international market. It will facilitate cross-border data sharing and collaboration, unlocking new opportunities for enterprises and fostering global competitiveness.

Conclusion

Data-driven decision-making is set to become the cornerstone of future engineering project management. With its seamless integration of data, cloud technologies, intelligent query capabilities, and 3D visualization, CTCI Digital Twin effectively bridges the EPC and O&M phases. This not only reduces maintenance costs and operational risks but also brings significant environmental and economic benefits.

As this technology continues to evolve, it will pave the way for even smarter and more automated project management, driving greater efficiency and accuracy. It will also revolutionize the industry and bring new opportunities.