Sustainable Governance

永續治理

Leading the Way: CTCI Engages with Vendors in Joint Stride toward Net Zero Emissions

As a company committed to the global sustainable development by utilizing its core expertise, CTCI expects its vendors to do the same. This is why CTCI has implemented various plans and measures to influence its vendors’ behavior, as well as encouraged these vendors to influence their own vendors’ behavior. Such process helps CTCI improve the sustainability performance across the entire value chain.

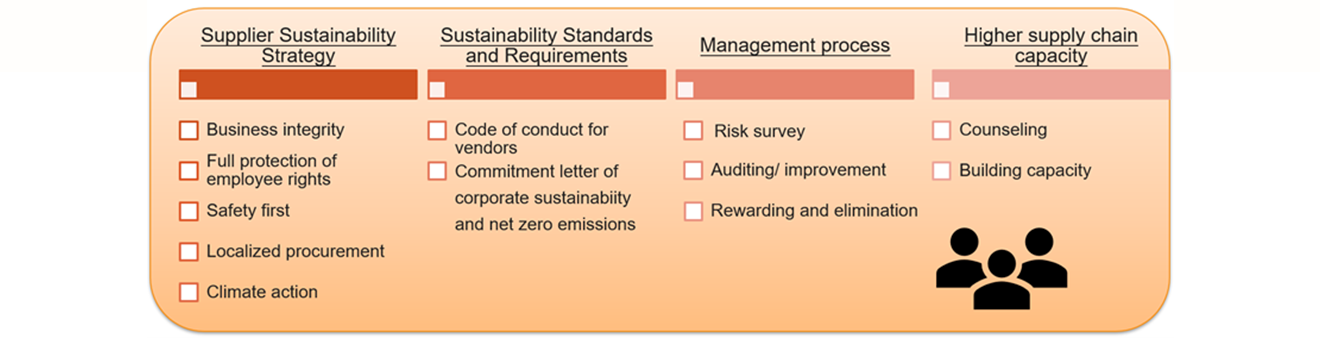

In this article, we provide an overview of CTCI’s four-step framework for sustainable supply chain management. The first step, “strategy for vendor sustainability,” lays the foundation, and is followed by the second step, setting “norms and requirements for a sustainable supply chain.” In the third step, “management process ,” CTCI carries out risk assessments, audits, improvement plans, and in the process rewards well-behaving vendors as well as disqualifies ill-behaving vendors. In the last step, the “supply chain capacity enhancement” stage, CTCI provides guidance support and capacity-building advice to strengthen the supply chain’s capacity. By setting goals and targets, the vendors continue to improve.

To ensure the success of the sustainable supply chain effort as well as the alignment with CTCI Group’s overall sustainable development strategy, the sustainable supply chain strategy and the implementation results are presented to the board of directors each year. The board would then make relevant decisions and oversee the overall process. CTCI seeks to leverage its industry-leading position to incentivize vendors in advancing sustainability.

Establish “Supplier Alliance for Net Zero Emissions’’ to Reduce Suppliers’ Emissions

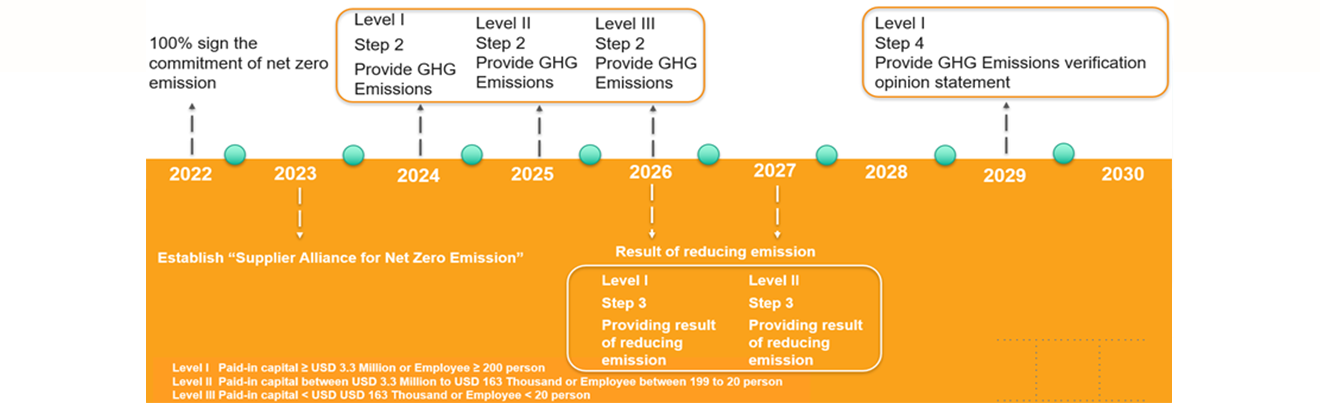

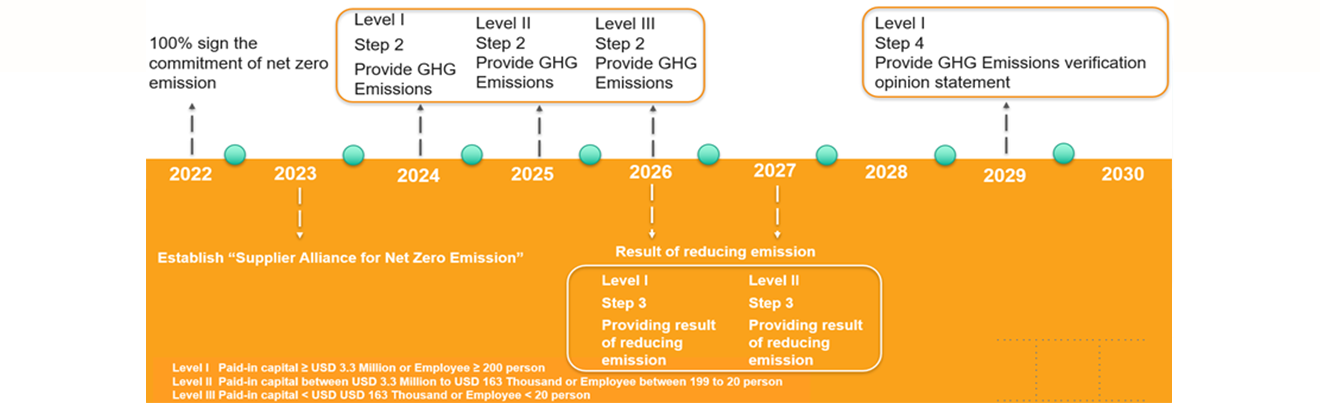

With the goal of "green engineering" in mind, CTCI adopts a triple-strategy that includes “green technology, green contracting, and green investment” to reduce carbon emissions throughout the entire lifecycle of the engineering projects, which spans across the construction, operation, and dismantling stages. This approach allows for a shared benefit of energy conservation, carbon emissions reduction, and resource reuse with our owners globally. Since reducing the embedded carbon is a key focus, the following actions have been implemented. Beginning from 2016, CTCI has requested all suppliers to sign “letters of commitment on corporate governance and net zero emissions” to show that they are serious about sustainability and net zero. Due to the growing trend in cutting emissions in recent years, the emissions reduction demands that CTCI received from its clients, as well as CTCI’s own desire to reduce the environmental impact, CTCI has established the CTCI Supplier Net Zero Alliance at the Supplier Meeting in March 2023 to minimize such impact as well as meet the customers’ demand for emissions reduction. During the meeting, CTCI announced the goal of the alliance, implementation procedures, as well as the plan for continuous engagement and emissions performance tracking, with an aim to encourage emissions reduction across the entire industry chain. As the leader of this initiative, CTCI took the lead to share about the global trend and CTCI’s efforts in sustainability, trying to influence and help small and medium-sized companies in striving for 50% reduction in carbon emissions by 2030. Just like a customized weight loss plan can only be formed when the weight is known, CTCI has required all vendors to provide their emissions data and emissions reduction outcome, starting from 2024. However, the vendors’ reporting obligation will be differentiated based on their company size, levels, and by step.

CTCI has also established a communication channel called "Sustainability Insights," through which CTCI regularly provides the alliance members with sustainability-related information. This includes CTCI’s bimonthly ESG E-Newsletter and the publicly accessible courses on the CTCI Learning platform, which allow vendors to build capacity. The channel also offers a mix of publicly available government resources, such as greenhouse gas inventory tutorial videos, inventory operation guidelines, and information on government support and subsidy programs. This allows CTCI to enhance the alliance members’ awareness on sustainable development and assist them to improve their capabilities.

Capacity-Building Measures and Awards Scheme to Help Vendors Improve Carbon Management

In addition to establishing the Supplier Alliance for Net Zero Emissions, which serves as a platform for companies to exchange their experience of emissions reduction, CTCI has also introduced capacity-building measures to help vendor improve carbon management. One measure is to support the government’s guidance program and introduce the external consultants to the vendors, so that the vendors are given on-site guidance.

The guidance process begins with educating and training the vendors, followed by factory visits to determine the primary energy-intensive equipment. Next, advice on energy-saving and carbon emissions reduction are provided. Based on the energy consumption data provided by the vendors, their carbon emissions are then calculated and compiled into a report. This process is carried out annually to help CTCI keep track of the vendors’ carbon emissions and form an emissions record.

To ease the burden on vendors and encourage them to actively transform into a low-carbon business, CTCI would also enquire the Taiwan Green Productivity Foundation, Foundation of Taiwan Industry Service Foundation, and the Metal Industries Research and Development Centre for the potential government subsidies for carbon management. The idea is that the implementation scope of the "Low-Carbon and Smart Upgrade Transformation Subsidy Program for Large Companies Leading Small Companies" should not only be confined to subsidiary companies within a corporate group, but should also be extended to external vendors. The vendors can then apply for government subsidies for their low-carbon projects, such as improvement on consumable materials, equipment procurement, as well as research or verification fees. The goal is to exert influence on a larger scale and build long-term, stable relationships with the vendors.

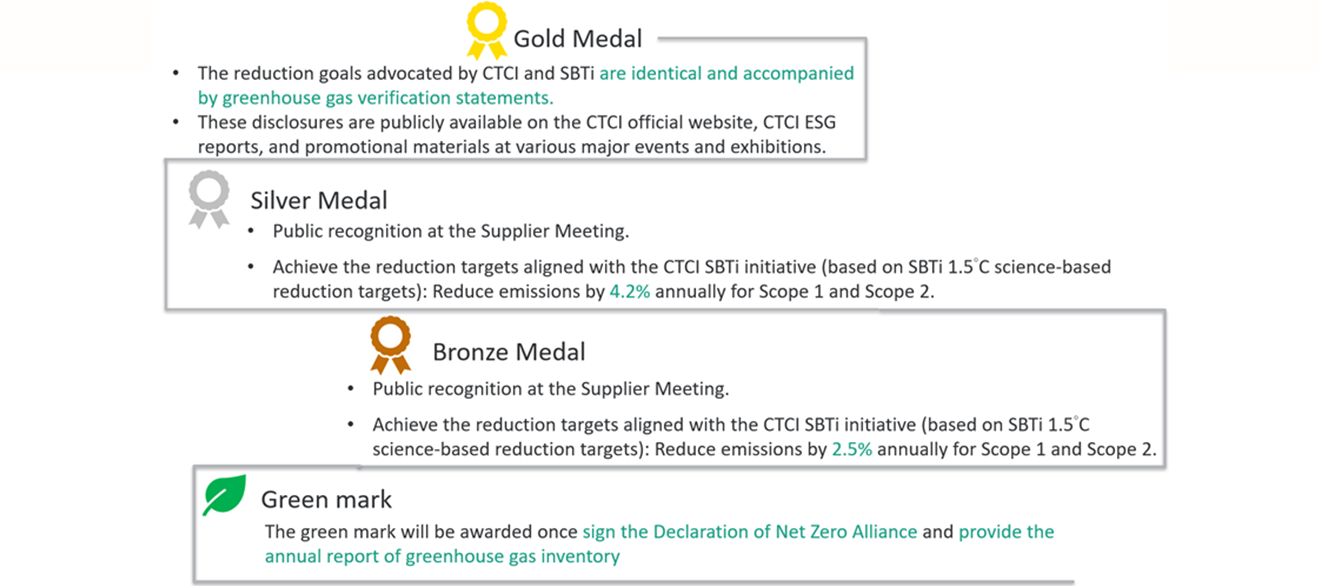

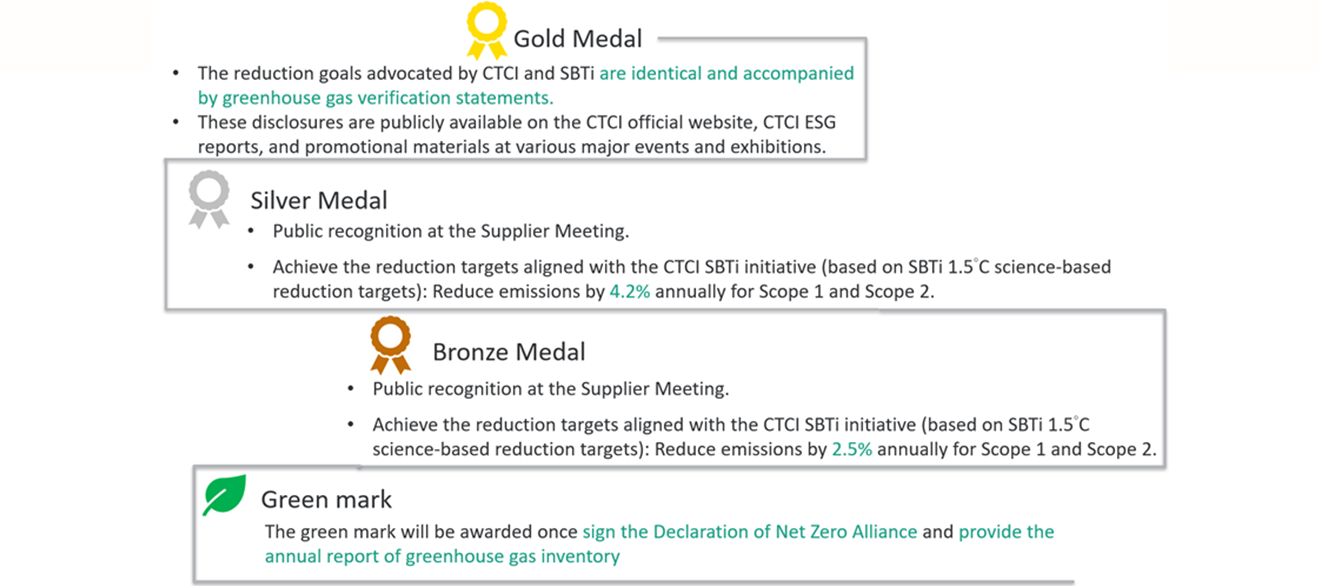

To encourage the vendors to reduce greenhouse gas emissions, CTCI has arranged an awards scheme, which includes the green label, golden award, silver award, and bronze awards. The label and awards will then become one of the criteria determining which vendor should be prioritized in the selection process. Vendors that excel in emissions reduction will receive public commendation at the CTCI Supplier Meeting. Vendors that achieve their reduction targets and provide emissions verification statements will have their accomplishments publicly disclosed on the CTCI website, in CTCI’s ESG Reports, as well as on the promotional materials for major events and exhibitions.

Results and Outlook

Currently, 172 vendors have joined CTCI’s Supplier Alliance for Net Zero Emissions. Among them, 112 companies have completed the guidance process. Based on the assessment of their factory equipment’s energy consumption and their pain spots, CTCI has provided them with feasible short-term, medium-term, and long-term measures and strategies that help them save energy and reduce emissions. Six companies have implemented the improvement plans, saving 475 metric tons of CO₂e per year.

From time to time, CTCI has joined forces with the CTCI Education Foundation, legal entities, and private organizations to host sustainability engineering symposiums, hold government guidance and subsidy program briefings, and host environmental education activities. Vendors are strongly encouraged to get involved, and in the process CTCI exerts greater sustainable engineering impact as the leader of Taiwan’s engineering sector. Looking forward, CTCI will remain committed not only to reducing its own emissions, but also to supporting the vendors’ sustainable performance across the globe. By engaging its vendors, CTCI is keen to make the world a much better and sustainable place to live in.