Eco-friendly Innovation

綠色創新

Introduction to Fly Ash Water-Washing Technologies

For many years, the fly ash generated at Taiwan's incineration plants undergo stabilization processes to form stable products which, in turn, are sent to the landfill for burial. This long-established disposal practice, along with plans to establish new landfill sites being hampered by resistance from the locals, have resulted in a severe shortage of landfill space. Designed to effectively recycle resources, fly ash water-washing process can treat the fly ash generated after incineration to reusable conditions for final disposal by recycling institutions, with an eye toward resolving the problem of insufficient landfill capacity, reducing environmental pollution, and improving resource recycling efficiency. Therefore, fly ash water-washing technologies will be one of the active development and application technologies of incineration plant operation in the future. ECOVE Environment Corp. (ECOVE), an affiliate of CTCI Group, currently operates nine large-scale urban incineration plants in Taiwan and two in Macau, treating more than 2.5 million tons of waste annually with excellent results. In recent years, as domestic incineration plants are progressively due for overhaul, ECOVE evaluated the feasibility of incorporating fly ash water-washing technologies into the overhaul plan, thus elevating resource recycling performance, and realizing the goal of circular economy.

Current State of Affairs on Fly Ash Water-Washing Technology Applications in Taiwan

When waste is incinerated, it generates a portion of the bottom slag and fly ash, which need to be retreated (fly ash includes boiler ash and the reaction ash that comes from removing the acidic and harmful substances from the exhaust gas). Among them, the bottom ash is general waste, which can be used as recycled aggregate in public works after being treated to meet the requirements of the Management Method for the Reuse of Incineration Bottom Ash in Waste Incineration Plants. Examples of recycled aggregate include controlled low-strength materials (CLSM) that are used for backfilling of drainage trenches, or can be made into concrete bricks. Contrary to bottom ash, fly ash contains a high concentration of dioxin and heavy metals, and is classified as hazardous waste. As a result, the difficulty and cost of treating fly ash are high. Before fly ash water-washing and reuse technologies were developed, fly ash could only be stabilized and sent to the landfill for final disposal. That said, as fly ash water-washing and reuse technologies become increasingly mature these days and can yield resource recycling benefits, these technologies will become the mainstream technologies for treating fly ash in incineration plants in the future to come. After years of fly ash water-washing experimental process verification, the current fly ash water-washing technology can greatly reduce the harmful substances. To avoid affecting the product quality of the recycling institutions and the corrosion of the treatment equipment, the chloride content of the water-washed ash is required to stay below 3% before being sent to major recycling institutions such as cement plants (with a chloride content below 1%), steelmaking dust ash treatment plants (chloride content below 3%) for recycling (see Note 1). However, since most incineration plants are subject to regulations that prohibit discharge of wastewater within the plant, it is impossible to set up fly ash water-washing plants within the incineration plants. At present, only some incineration plants that are not subject to wastewater discharge regulations, such as Beitou Incineration Plant and Muzha Incineration Plant in Taipei City as well as Taoyuan South Incineration Plant, can set up fly ash water-washing systems within the plant area.

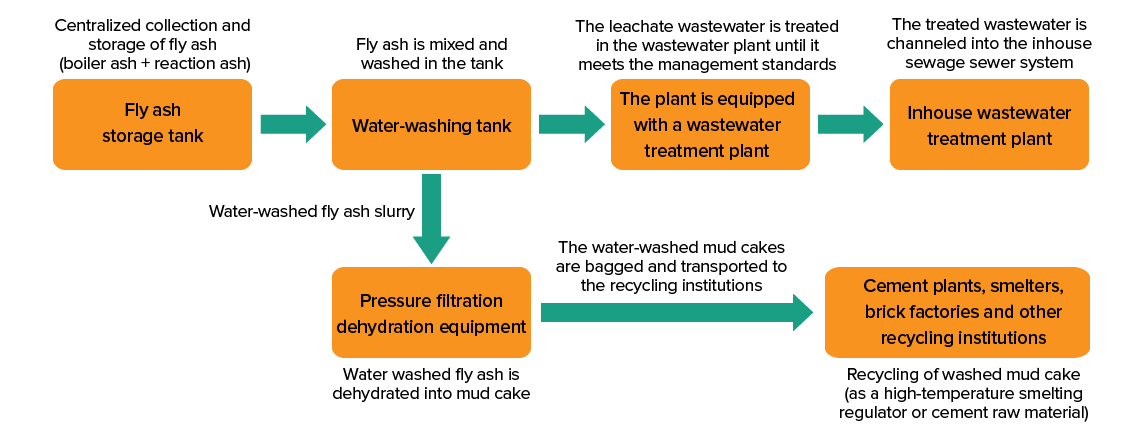

Introduction to the fly ash water-washing process

The fly ash water-washing process involves collecting the fly ash to be washed to the storage tank for temporary storage, before transporting it to the washing tank for mixing and washing (some processes add chelating agent to remove heavy metals). The fly ash is leached and dehydrated to produce mud cakes, which are then sampled and tested until qualified for being transported to the recycling institutions. The leachate in the washing tank is pumped to the wastewater plant, and the treated leachate is discharged to the inhouse wastewater treatment system (please refer to the figure below). At present, the treatment process of the fly ash water-washing equipment of the incineration plants that has been in stable operation domestically varies as each incineration plant and recycling institution has different processes and acceptance standards. Therefore, the processes adopted by the fly ash water-washing systems may range from single-wash to multiple-wash, all with the ultimate goal of meeting the acceptance standards of the recycling institutions (see Note 2).

Introduction to the fly ash water-washing process

Recycling to Divert Fly Ash from Landfills

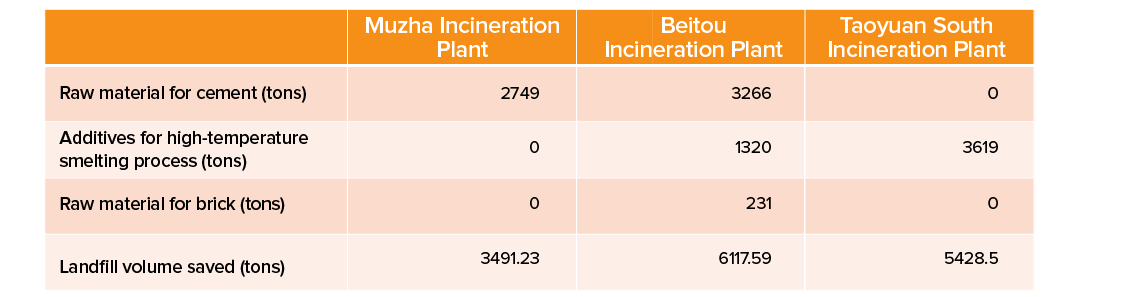

Taking large-scale waste incineration plants in various local counties and cities as an example, the Beitou Incineration Plant and Muzha Incineration Plant in Taipei were the earliest to introduce fly ash water-washing systems. The fly ash from Muzha Incineration Plant is all water-washed and sent to the cement plant as raw materials for cement, achieving the goal of full recycling. In Beitou Incineration Plant, however, full recycling is not achieved currently, as only a portion of the fly ash is water-washed and treated before being sent to the cement plant and steelmaking dust collection and ash treatment plant. In addition to the two aforementioned plants, the Taoyuan South District Incineration Plant also introduced a fly ash water-washing system in 2022, and all the water-washed fly ash was sent to the steelmaking dust collection and ash treatment plant. There, water-washed fly ash can replace alkaline substances such as hydrated lime that is used as an alkaline agent in the high-temperature smelting process. The differences in the reuse of fly ash after water-washing in the three aforementioned plants are shown in the table below (see note 3). Recycling incineration fly ash after washing with water can reduce the use of landfill capacity. Furthermore, recycling water-washed fly ash as cement raw material and alkali agent in high-temperature smelting processes can also reduce the environmental burden caused by the extraction and processing of natural raw materials, such as limestone, into industrial raw materials.

Comparison of differences in the recycling methods of water-washed fly ash in incineration plants in 2022

Future outlook

Nowadays, climate change and environmental sustainability have become increasingly important global issues. The fly ash water-washing process can convert waste that originally needed to be buried into reusable resource materials, which has better economic benefits compared to the original landfill treatment and is in line with the national net zero strategy that dictates zero waste and resource recycling. Domestic incineration plants have also incorporated fly ash recycling technology in their overall planning consideration for life cycle extension upgrades at the end of the operating period. In the future, as a practitioner of resource recycling with nearly three decades of rich experience in waste management and recycling under the belt, ECOVE will ceaselessly develop technologies that keep pace with the times, offer holistic resource recycling services through the integration of green technologies, and find the best solution for fly ash recycling while balancing operational quality and environmental friendliness. Progressively, we will realize the goal of zero waste of resources and full recycling of materials, and progress towards the vision of net zero emissions by 2050. References: Note 1: Beitou Waste Incineration Plant, Taipei City Government Environmental Protection Bureau Note 2: Feasibility Assessment Plan for Constructing Fly Ash Water-Washing Plant in Taichung City - Final Draft of Final Report by Hong Yu Environmental Consultants Ltd. Note 3: Taipei Beitou Waste Incineration Plant’s 2022 Annual Waste Incineration Plant Operation Results Report; Taipei City Muzha Waste Incineration Plant’s 2022 Annual Waste