Sustainable Governance

永續治理

IoT Technology Helps Enhance Site Management and ESG Performance

The introduction of information technology is the key to the development of the intelligent engineering, procurement, and construction (iEPC) projects at CTCI, the first step of which involves building an internet of things (IoT) environment. IoT means connecting various "objects" with built-in sensors through wireless or wired approach, which allows humans to be able to monitor, process, and analyze the information through the network to improve work efficiency. In recent years, another concept called the new generation artificial intelligence of things (AIoT) has risen thanks to the development and combination of new technologies such as AI, big data, blockchain, 5G, edge computing, and cloud computing. AIoT, which is the combination of IoT and AI, is undoubtedly a basic application vehicle for enterprises to collect important information generated in the business process, and is also a key technology to assist enterprises in sustainable development. AI helps the experienced leadership make the best judgment and form decisions, which in turn enhances the company’s ESG (environmental, social, corporate governance) progress and bring in a safe and comfortable working and living environment. In this article, the author will talk about how CTCI’s Group Research and Innovation Center (GRIC) uses AIoT technology to gradually allow construction sites to become smartly managed and achieve ESG goals.

Achieving sustainable development with intelligent site management

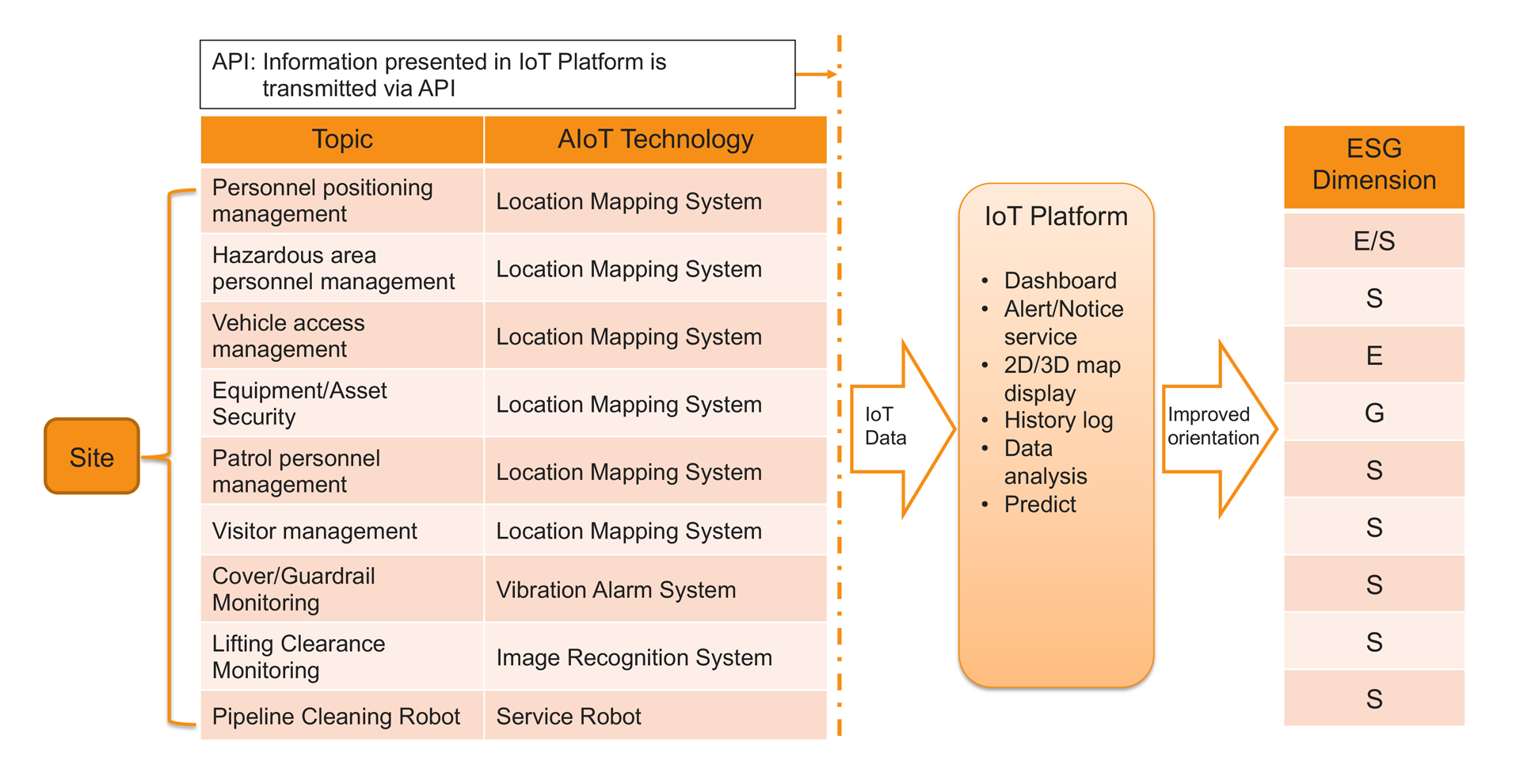

There are many dangerous facilities at construction sites, and construction sites vary in their management practices with regard to the entry and exit control of staff and vehicles, the distribution of machines, and the storage of construction equipment. HSE (health, safety, and environment) incidences occur due to distraction and negligence, something neither the victim, family members, or the company is happy to see. CTCI has continued to improve site safety management by introducing intelligent technologies. Intelligent technologies not only help sites remain safe, but also significantly contribute to the promotion of ESG. The “E (environment)” aspect of ESG includes measures such as energy saving, carbon reduction, circular economy, resource recovery or reuse, waste management or reduction, consuming green electricity, and ecological conservation. The “S (social)” aspect is about improving labor rights, labor conditions, gender equality, product responsibility, privacy protection, and promoting social mobility. The “G (governance)” aspect is about quantifiable performance and management system, legal compliance system and structure, integrity and sustainable operation, risk management, information security, external communication and information disclosure. Making good use of AIoT technology in construction sites can significantly help promote every aspect of ESG, as shown below.

Site Management Topics and Their Corresponding ESG Aspects for Improvement

A Case Study on AIoT Technology Application

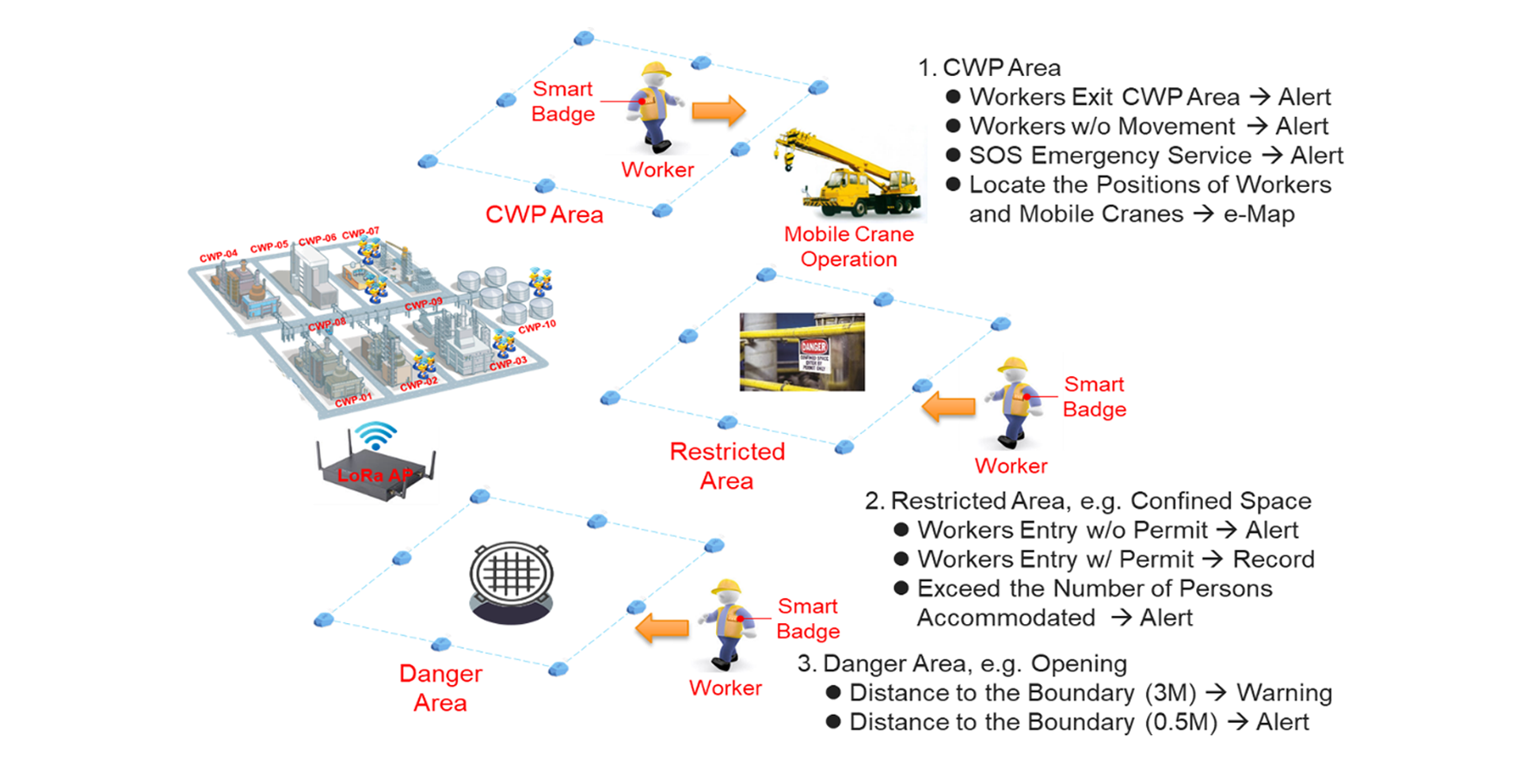

‧Location Mapping System The location mapping system (LMS) is a tool developed by CTCI’s GRIC for intelligent site management. The system works with LoRa (long-distance wireless communication network) in the low-power wide-area network (LPWA). It is equipped with Bluetooth technology (short-distance wireless communication network), and allows users to access necessary information from the services provided on the cloud platform to facilitate management work. It has the following features, each with corresponding ESG aspects and benefits. 1. Positioning Management of Construction Site Personnel (E dimension: Calculating the amount of waste generated by site personnel; S dimension: Quantifiable performance management on absenteeism) By using the positioning identification cards that personnel carry with them, we can have a real-time understanding what is going on at the work sites. Bluetooth beacons that emit signals at fixed points serve as a positioning reference, and by transmitting the positioning information through the radio wave, we can have clear understanding on the dynamic positioning of all personnel, establish electronic fences, find specific personnel in real time, and conduct intelligent assessment. It also helps better understand the absenteeism statistics, working hours statistics, and behavior monitoring. It allows distress signals to be sent, encourage staff to do recycling, and allows historical track playback and other functions to maintain the order of the construction sites. 2. Personnel Management in Hazardous Areas (S dimension: Improved labor conditions) To prevent personnel from entering dangerous areas inadvertently, such as going into an area where there are potholes on the ground or into an area where heavy objects are being hoisted, Bluetooth beacons are placed on the periphery, and the safety distance is set through the back-end platform to form an electronic fence-like control area (as shown in the figure below). Whenever a construction site personnel wearing the positioning identification card breaks into the control area, they will trigger the sound and flashing alarm device within the control area. The information on the trigger event will be sent to the back-end platform and the manager’s mobile device. The alarm can also issue warnings upon a person’s entry or exit to keep people safe.

Hazardous Area Control at Work Sites

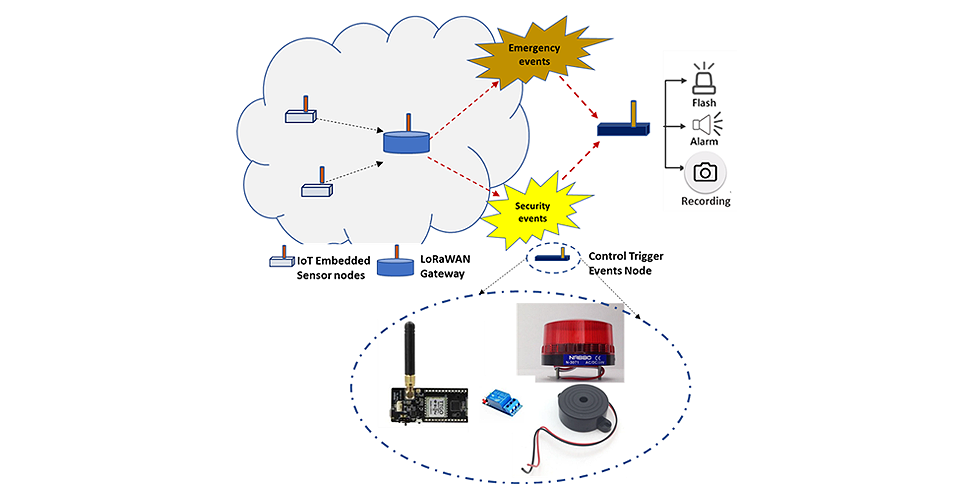

3. Vehicle Access Management (E dimension: Planning the best route for vehicle entry and exit to prevent blocking, waiting, or detour due to moving large vehicles) AIoT technologies allow us to count the number of vehicles that should arrive on site and their actual time of arrival and departure. With AIoT, we can chart out the vehicles at various areas, how this affects their actual arrival on site, and allocate appropriate routes. We can also input the vehicle information, such as vehicle number, vehicle type, and the contractor that is using the vehicle, into the system, which will then display the arrival status of large vehicles on the electronic map as well as provide a daily management report on all large vehicles. 4. Equipment/Asset Security (G dimension: Reduce theft and loss; lower the likelihood of repeated purchases and manufacturing) A positioning card is allocated to each valuable equipment upon reception and storage. Such information is then input into the back-end platform system. When an equipment is issued, the positioning card needs to be retrieved. If the valuable equipment leaves the storage area without retrieving the positioning card, the system would immediately alert the warehouse personnel. ‧Vibration Alarm System 1. Cover/Guardrail Monitoring (S dimension: Improved labor conditions) The most common major occupational incidents occur in the construction industry, which is falling from heights, as the national statistics on major occupational incidents shows. Although there has been a significant reduction in overall falling incidence from floor openings or roof edges over the years, 20% of the falling incidents are still attributed to floor openings. Given the importance of construction site safety, GRIC has developed a vibration alarm system, where sensors are placed on guardrails. The sensors are used to detect the robustness of guardrails and the status of cover opening. The sensors and IoT work together to help managers monitor in real-time. By collecting data, we can also help new employees or visitors who are unfamiliar with the construction site to pay more attention to openings. In the event of an accident, the system can also report it in real-time, thereby reducing the occurrence of falling accidents from unsafe openings and improving safety.

An IoT Structure on Triggers Alarm Events

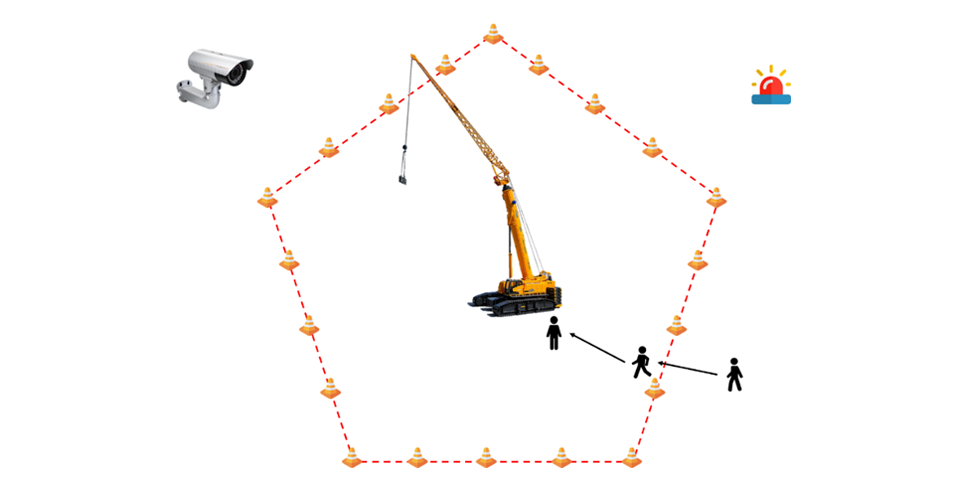

‧Image Recognition System 1. Clearance Area Monitoring for Lifting Operations (S dimension: Improved labor conditions) This intelligent image recognition system helps identify objects and issue warnings. The deep learning network is transferred to the embedded edge platform, and an alert area at construction site can be defined according to the recognized objects (such as traffic cones or warning signs). This helps to immediately identify whether the personnel and equipment inside the alert area meet safety requirements. Alerts can then be sent in the forms of sound, lighting flashes, or text messages to site managers and staff. This kind of on-site AI support helps reduce occupational incidences and casualties.

The Concept of a Construction Alert System

‧Service Robot GRIC is developing robots that can be used at construction sites to reduce the amount of manpower required and the likelihood of occupational incidences. 1. Pipeline Cleaning Robot (S dimension: Improved labor conditions) The camera system mounted on a pipeline cleaning robot allows staff to see the residual welding slag that remain on the pipelines’ inner walls, at the joints where valves open and close, and on the welding beads. The slag can then be removed by using brushes, blowers, or vacuum cleaners. In other words, "what can be seen can be removed." The robot can greatly reduce the risks of climbing, falling, and body injuries because traditionally it is impossible to know the amount of residual welding slag, thus requiring the staff to follow along the pipelines and use equipment that would not harm the surface of the pipelines and to knock off and blow away the slags from the weld beads at the joints. To do so, staff need to meander along dense pipelines and even need to build scaffolds so that they can reach higher positions, which endangers their safety.

Images Shot by a Pipeline Cleaning Robot

Conclusion

This article summarizes the current outcomes and benefits of the various AIoT applications developed by CTCI’s GRIC. The data that comes from the use of such applications can be further used for big data analysis in the future, which in turn helps to optimize project progress and manpower scheduling, as well as improve the project progress and manpower allocation efficiency. These excellent results point a clear pathway for ESG development in the future. CTCI will aim to adopt AIoT technology in managing all of its construction sites, and will continue to seek solutions for the difficulties it encounters currently, so as to move forward towards the goal of intelligent site management.