Eco-friendly Innovation

綠色創新

Innovative Green Engineering Helps CTCI Advance Towards Net Zero Emissions with Partners

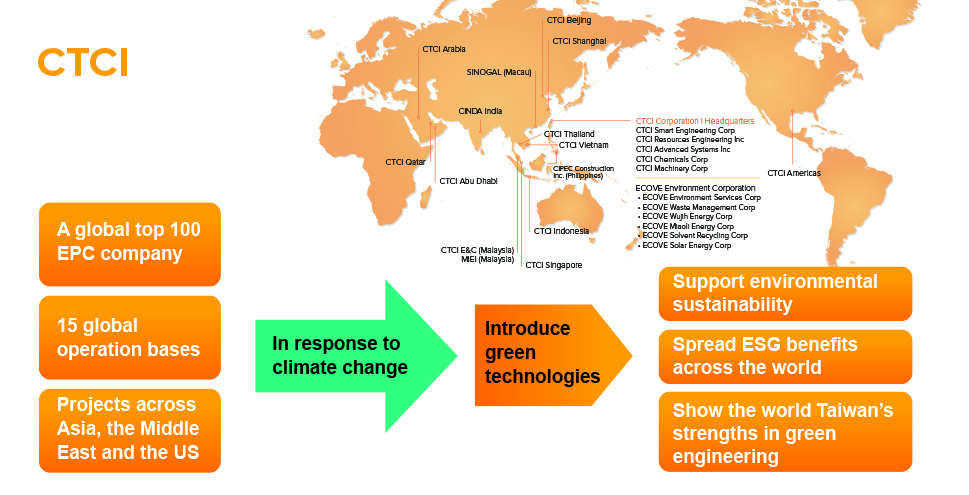

Committed to global sustainability through green engineering, CTCI adopts advanced technologies that are eco-friendly and energy saving for engineering designs, resulting in the efficient reduction of pollutants, energy and resource consumption, as well as environmental impact and expenditure. CTCI is committed to setting up the net-zero SBTi target through the Business Ambition for 1.5°C campaign, in terms of carbon reduction to expedite achieving net-zero emissions target by 2050.

CTCI is committed to global sustainability through green engineering

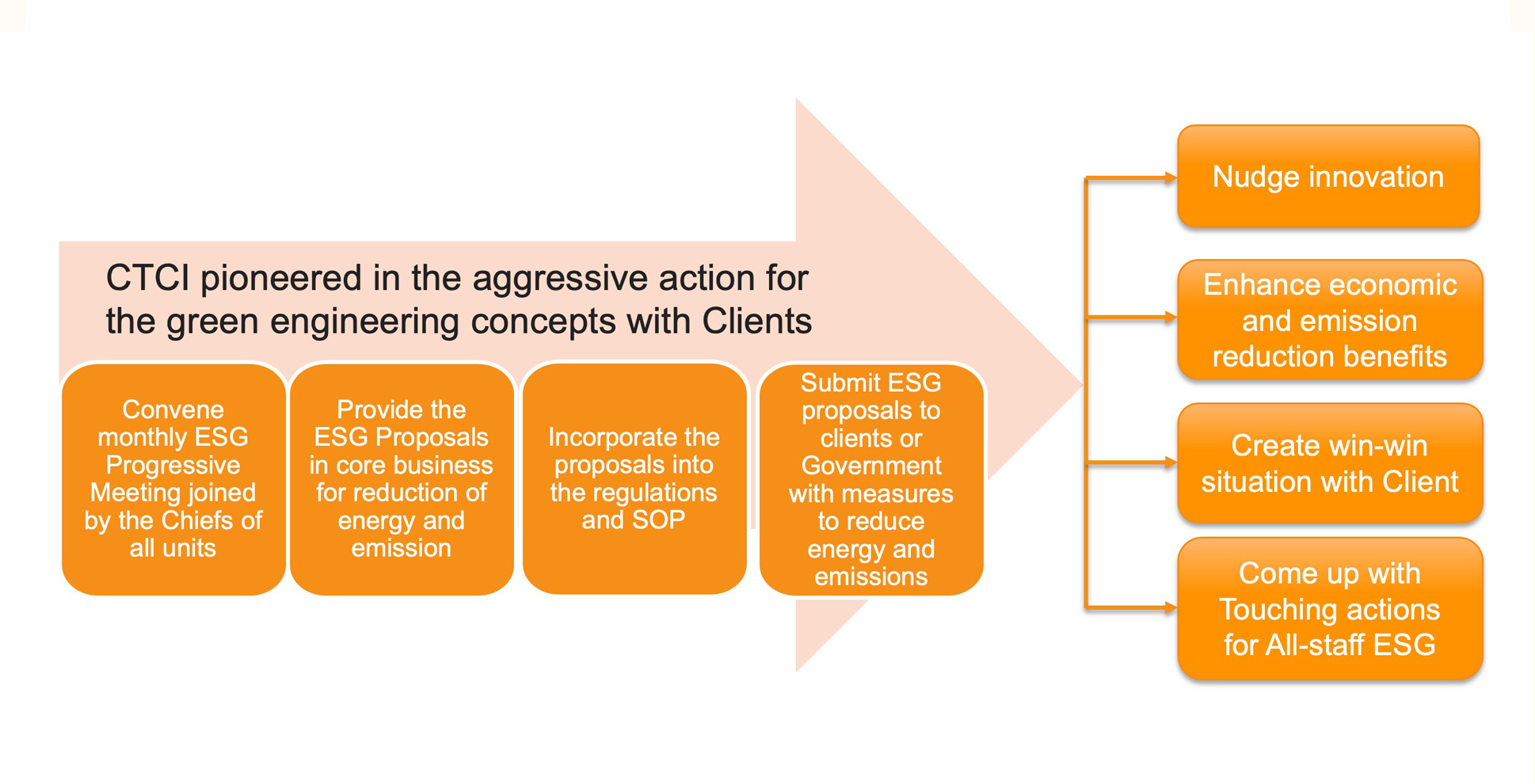

CTCI adheres to the concept of “Fulfilling Net-Zero EPC through Company-Wide Efforts.” To continue improving its green engineering effectiveness, CTCI began in 2020 a series of green engineering efforts, including encouraging colleagues to present progressive proposals to the owners by thinking outside contract terms. This not only brings economic benefits, but bring carbon reduction as well, creating win-win with the owners via innovate technology. As a sign of determination, the top management regularly holds intensive meetings, during which the directions of implementation are clarified, the effectiveness of implementations is reviewed, and the managers of each unit are asked to take full responsibility with diligent supervision. Since its implementation, CTCI Group has created progressive proposals every month, covering aspects such as power saving, energy saving, water saving and other aspects, with the following features:

CTCI brings mutual benefit to itself and clients through green engineering solutions.

Encourage innovation to break engineering bottlenecks

Innovation is an important element in CTCI corporate culture. Progressive proposals are innovative solutions to break the bottleneck found in green engineering. Below are a few examples of CTCI’s technical and process innovations: I. Technological innovation Despite having a strong technical foundation due to long-term engineering practice, the ever-increasing competitive and stringent environmental regulations compel CTCI to seek innovative technologies and enhance its engineering capabilities. For example: 1. Adopt value engineering technology: Value engineering provides alternatives to secure maximum value with optimized cost, all the while ensuring necessary functions. Over the years, CTCI has improved plant layout with value engineering technology, which not only creates project value, but also optimizes material quantity and construction work, greatly cutting carbon emissions.

By using value engineering technologies, CTCI not only optimizes the quantities of materials used and construction work, but also effectively cuts carbon emissions.

2. Apply the new technology: Such as using intelligent junction box instead of the traditional on-site instrument junction box. This helps save materials, construction manpower, and CO₂ emission. 3. Use renewable raw materials: Replacing some part of the cement with renewable raw materials such as fly ash or slag can not only reduce energy consumption, CO₂ emissions and material costs, but also enhance the concrete constructability and durability by reducing the hydration heat of concrete. 4. Use new materials and new construction methods: Compared with traditional insulation made by carbon steel pipe fabricated and welded at site, pre-insulated tubing connected by threaded joints are not only easy to fabricate, but also saves construction time and the amount of required materials and construction, resulting in lower carbon emissions. 5. Adopt new process: Thanks to the joint effort by manufacturers, CTCI optimizes processes by recycling purged water of the reverse osmosis system and reusing it as secondary water and backwash/chemical wash water for the super filter. This helps reduce water consumption, wastewater generation, and carbon emissions.

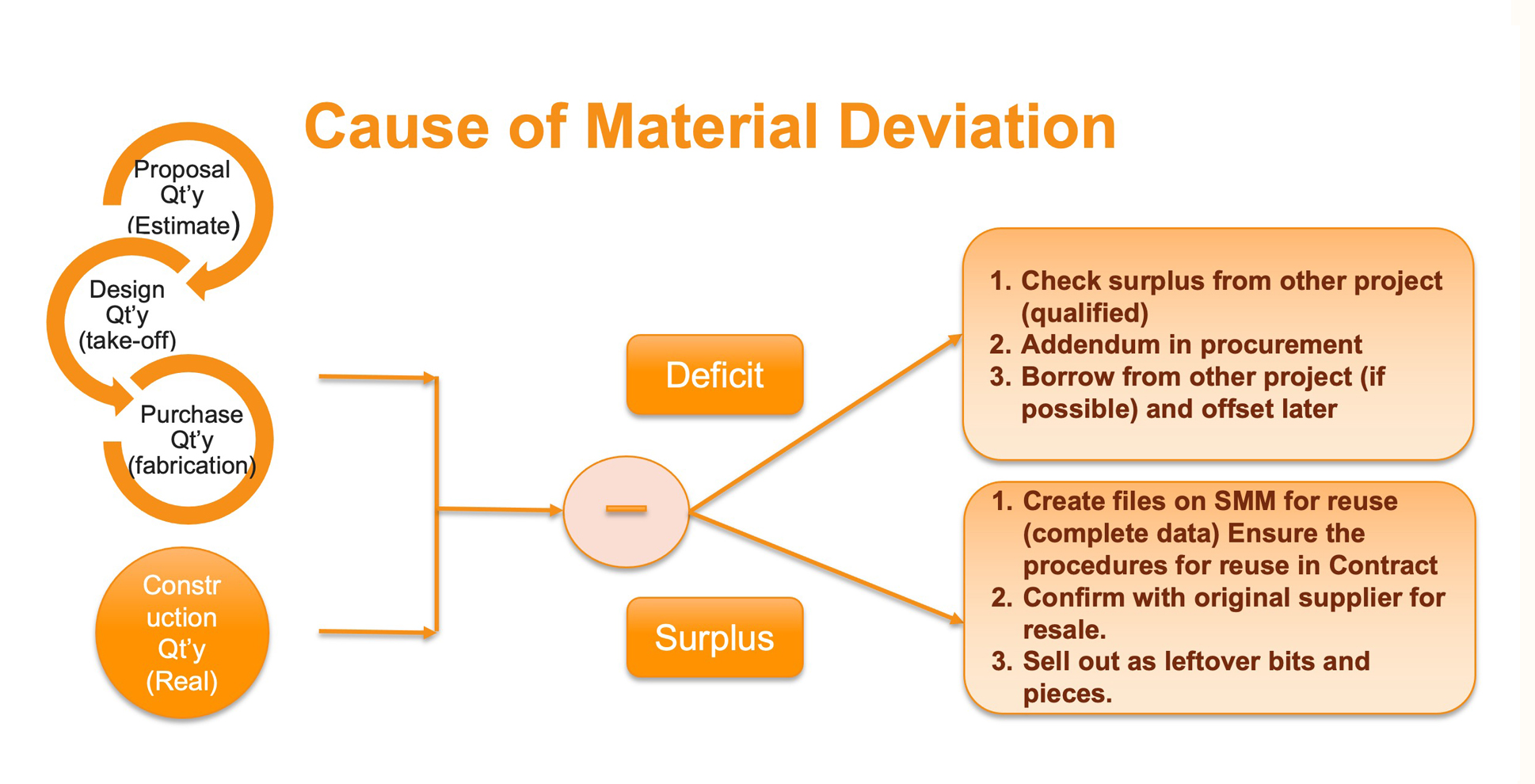

II. Process innovation The lifecycle of an EPC turnkey project can last many years, beginning with feasibility study, then going on to basic design, detailed design, procurement, installation, commission and handover to the owner. The whole process involves many actors, including owners, process licensor, main contractors, suppliers, and subcontractors. Due to the complexity of its nature, improving the efficiency of EPC project implementation is not only a key concern of CTCI, but also the focus of the progressive proposals. Examples include: 1. Recovery and reuse of the engineering surplus materials: Potential material quantity deviations may happen between the quoted (estimated) amount, the design (MTO) amount, the purchase (fabrication) amount, and the construction (actual) amount in EPC projects. To cope with this issue, CTCI established an engineering surplus material management system (SMM), an integrative platform for project surplus material information that can be used for matching, application, order, allocation, transfer, withdrawal, cost transfer and sale of project surplus materials among EPC projects to timely recover and reuse engineering surplus materials. This helps as well carbon emissions.

A flowchart of the recovery and reuse of engineering surplus materials

2. Online bid opening: Companies abroad are suggested to join bid opening online through video conference, which reduces business travels by plane. This helps protect the environment and improves carbon reduction effectiveness.

Creating win-win for CTCI and owners by improving economic and carbon-reduction benefits

Every CTCI progressive proposal requires benefit analysis in terms of carbon- reduction efficiency and economic benefit, as well as a pros and cons analysis to ensure the feasibility of the proposals. During quotation or execution stages, technical clarification information should be prepared to show owners the pros and cons of the proposals, before seeking approval for implementation. For CTCI, innovative solution has the advantages of carbon reduction and cost saving, which make CTCI more competitive. For owners, innovative solution helps them cut costs, save energy, and lower carbon emissions, thus achieving the win-win goal. In contrast to previous CTCI green engineering actions, which focused on applying green technology that stayed within bounds of the contract to achieve energy conservation and carbon reduction, progressive proposals, on the other hand, encourages innovation and break contract limit, so that green engineering can be deployed at a higher level. To achieve company-wide ESG goal, progressive proposals must become part of each discipline’s SOP and be advocated, so that each employee can implement it in his or her daily routine.

Conclusions

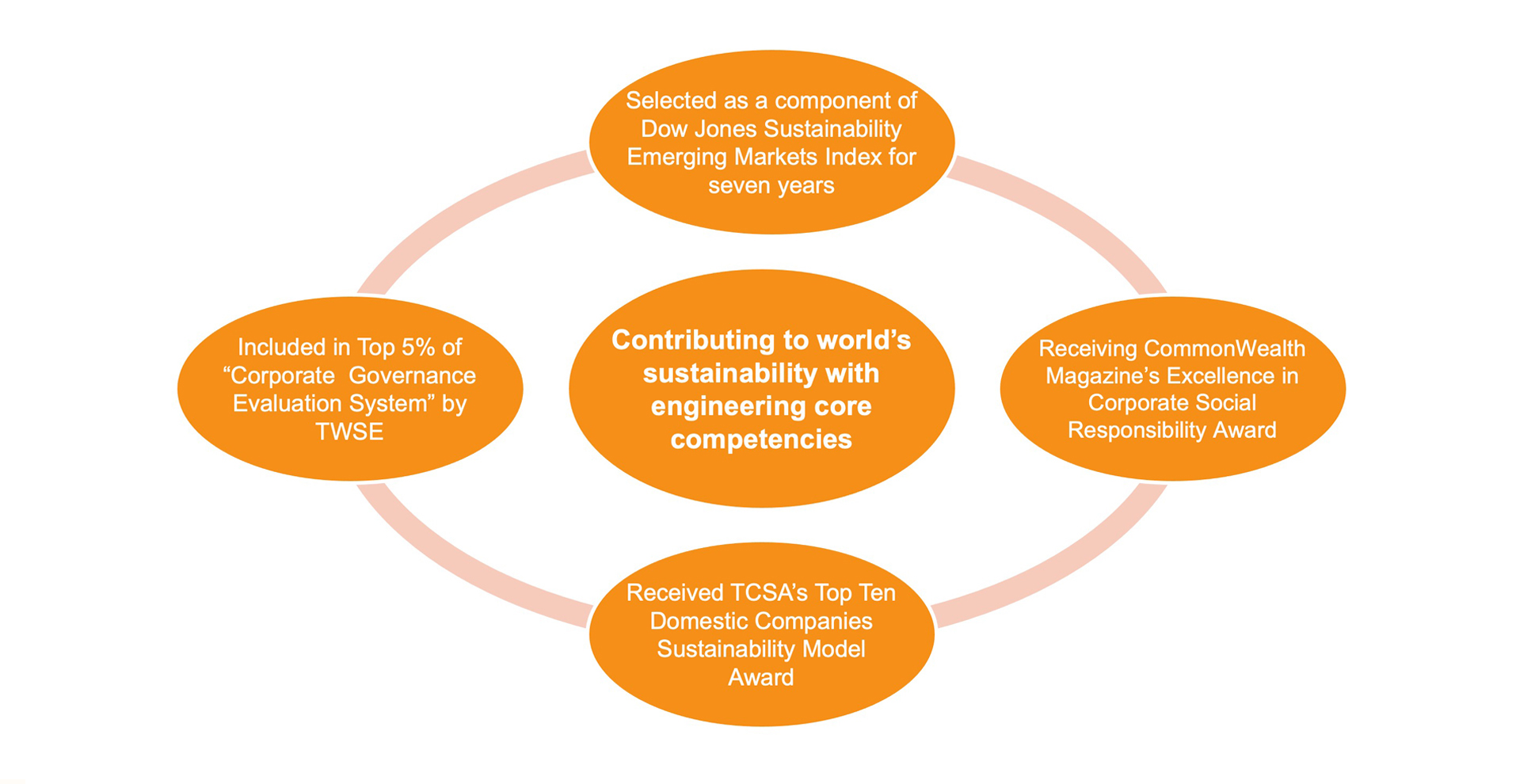

Contributing to world’s sustainability with its engineering core competencies, CTCI has received various sustainability-related recognitions and awards in Taiwan and abroad, including being selected as a component of Dow Jones Sustainability Emerging Markets Index for seven consecutive years; being awarded TCSA’s Top Ten Domestic Companies Sustainability Model Award; receiving once again CommonWealth Magazine’s Excellence in Corporate Social Responsibility Award; being included in Top 5% of "Corporate Governance Evaluation System" by TWSE; receiving A- and being recognized as Leadership band in CDP Supplier Engagement Rating. CTCI is truly an ESG role model in Taiwan’s engineering industry.

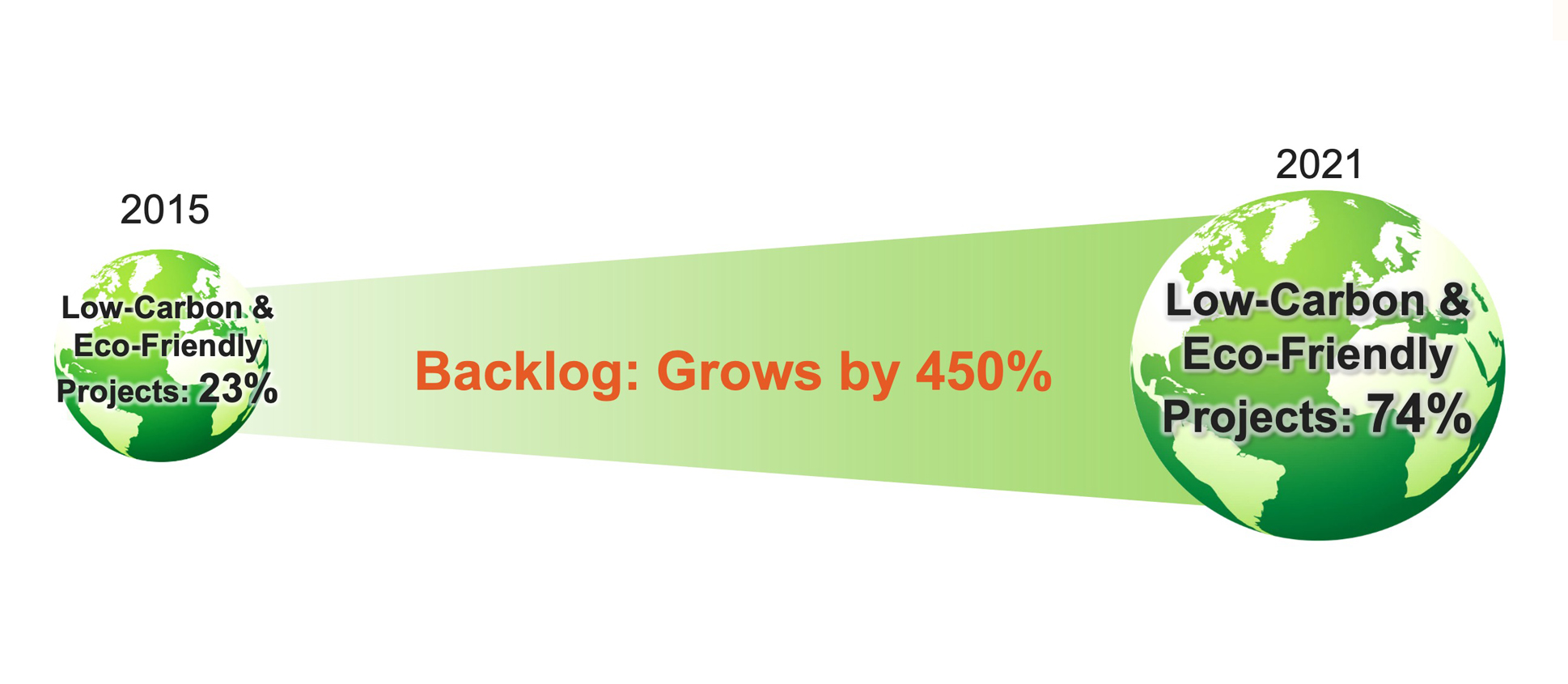

After COP 26 summit, countries around the world are now focused on achieving net-zero emissions globally by 2050 and to finalize a global emissions trading system. In support of the global trend in carbon reduction, CTCI’s green and low carbon engineering business so far has grown 450% compared to the year 2015. Moreover, CTCI joined "Taiwan Alliance for Net Zero Emissions” and “Taiwan Net Zero Emissions Association," and is determined to continue its green engineering improvement and promotion effort. CTCI is now committed to achieving zero carbon emissions at all its offices by 2030 and zero carbon emissions at all offices and fabrication sites in 2050.

CTCI joins the Net Zero Initiative to work with corporate leaders in leading the whole industry towards the goal of carbon neutralization.