Sustainable Governance

永續治理

Bringing Sustainability to EPC Company´s Supply Chain Management

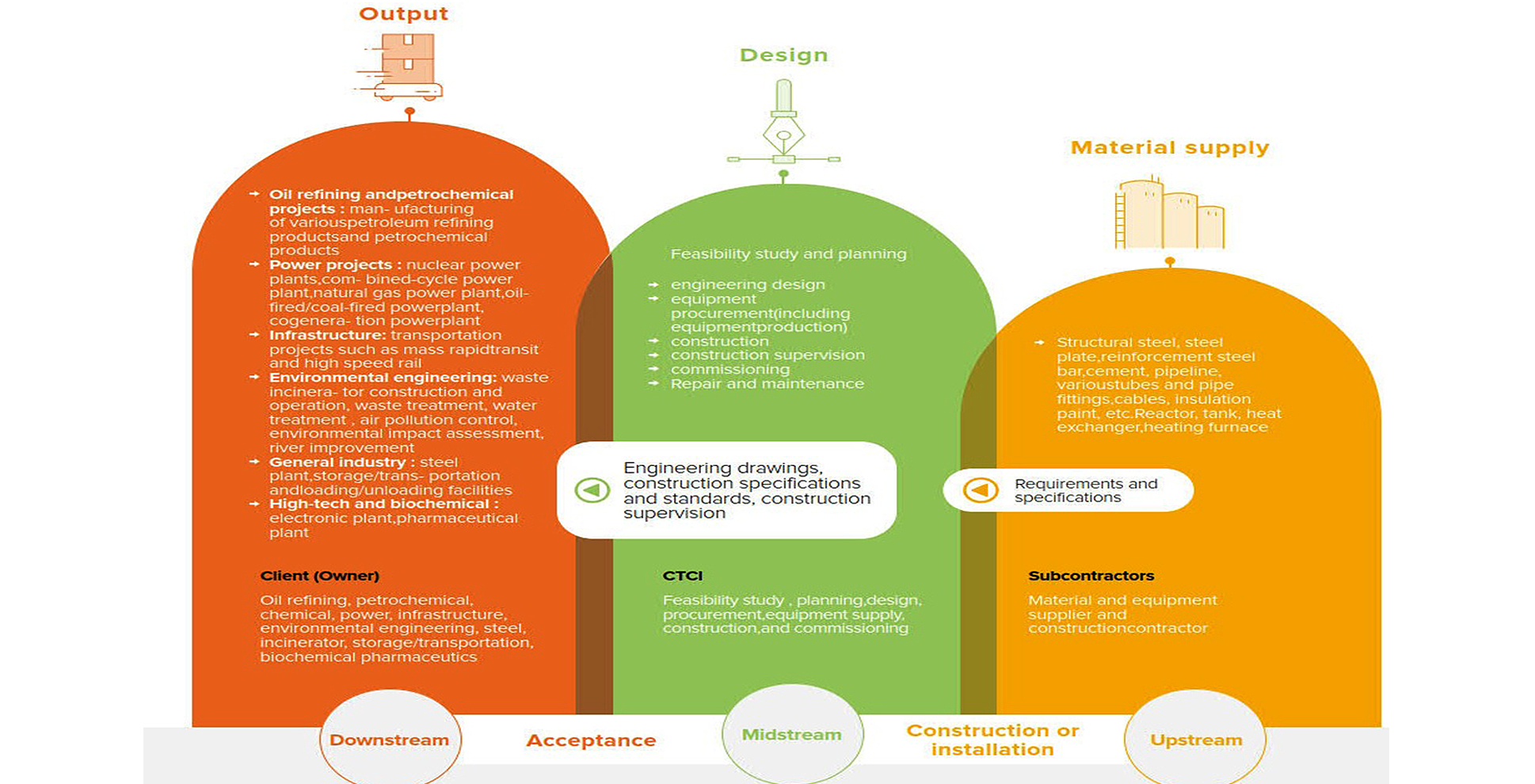

Engineering, procurement, and construction (EPC) is a midstream industry within the overall engineering industry chain, which involves high level of expertise and complexity. An EPC company offers professional services such as feasibility analysis, planning, design, procurement services, equipment supply, construction, and commissioning according to upstream client needs. In the process of doing so, the EPC company needs to work with downstream subcontractors and suppliers to secure materials, equipment, and construction services.

As such, suppliers are critical to the success of EPC projects. Good supplier management ensures that the materials and construction services procured meet client requirement on quality and delivery schedules. However, given the increasing importance of sustainability to EPC companies nowadays, there is a need to introduce sustainability to supply chain management.

At CTCI, a sustainable supply chain means fostering resilient supplier relationships that meet CTCI’s sustainability criteria, with the purpose of lowering CTCI’s operational and CSR (corporate social responsibility) risks. When a company has tens of thousands of suppliers—which is the case of CTCI— it is of paramount importance to have a management framework in place, engage suppliers to form a valid strategy, categorize suppliers, raise supplier awareness, set up assessment criteria, and evaluate supplier performance.

CTCI´s Position in the Industry Chain

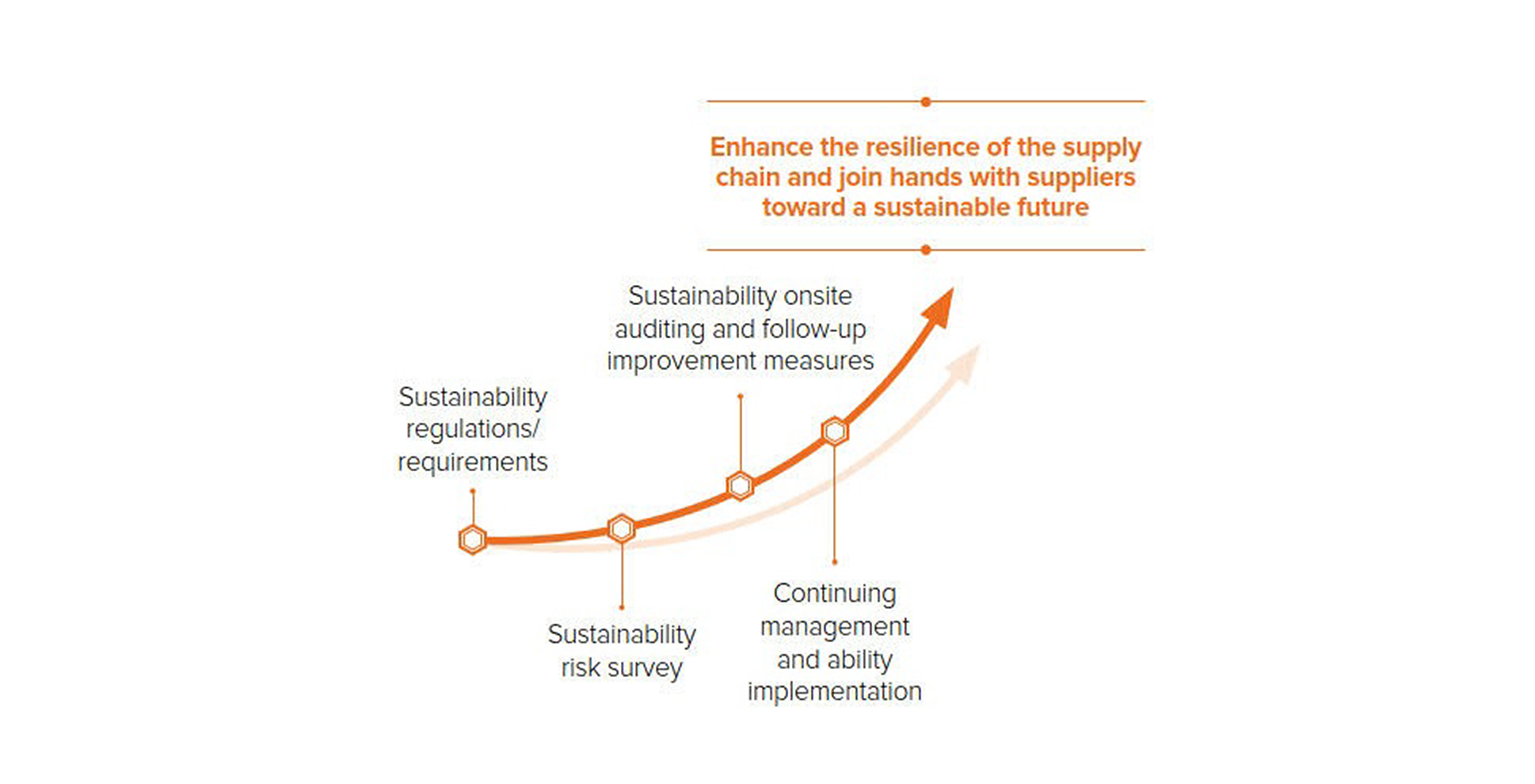

The following are seven aspects of CTCI´s sustainable supply chain management: 1. Sustainable supply chain management framework A sustainable supply chain management framework serves as guidance and self-check mechanism for enhancing the sustainability and resilience of supply chain, while lowering supply chain risks. At CTCI, the framework is comprised of four steps: 1. Sustainability requirements 2. Sustainability risk survey 3.Onsite sustainability audit and improvement measures 4. Continuous management and training.

Supply Chain Code of Conduct

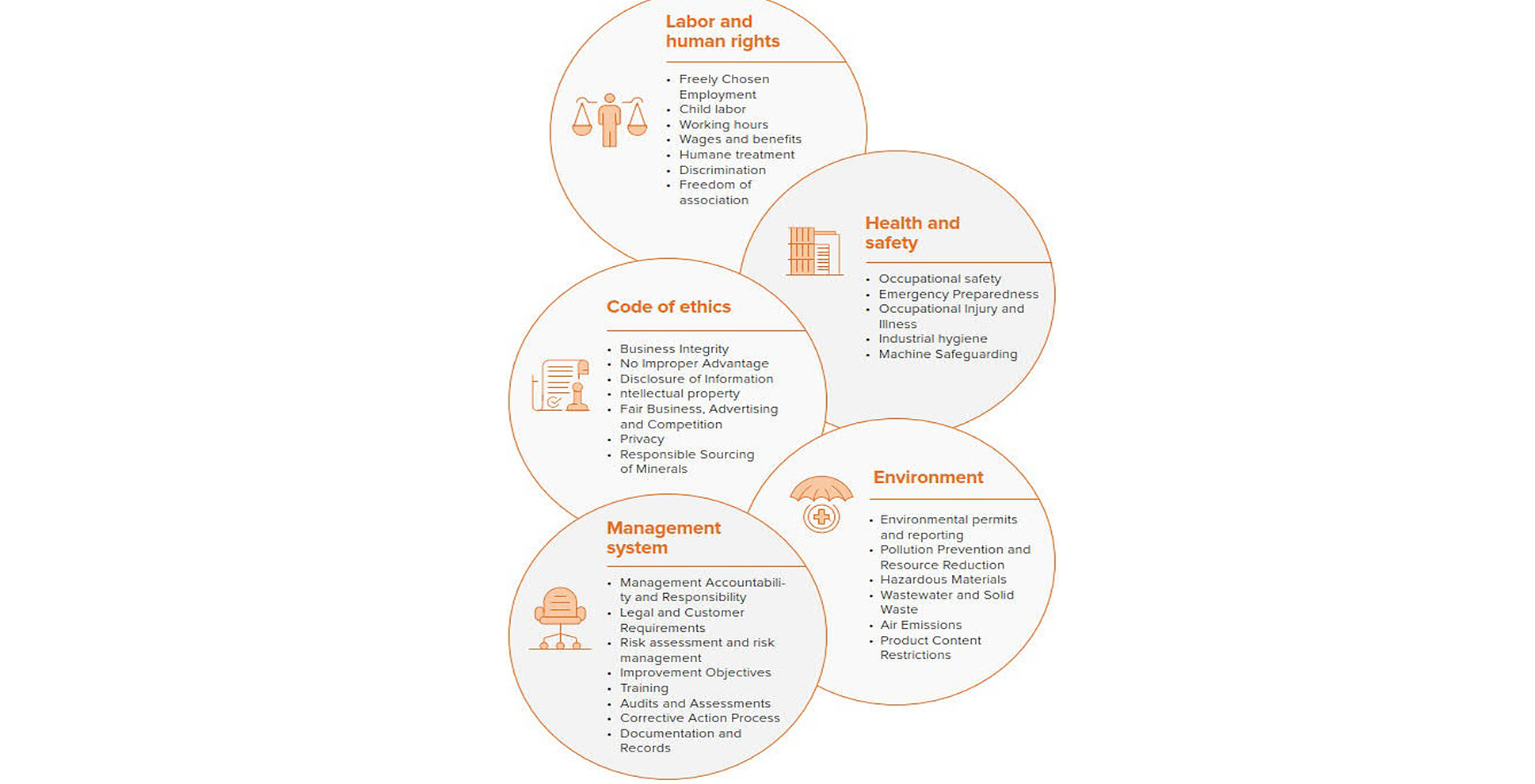

2. Supply chain code of conduct The purpose of supply chain code of conduct is to align suppliers´ values with that of the EPC company. CTCI is a group of companies committed to corporate social responsibility, and has therefore established CTCI Vendor Code of Conduct that refers to various global initiatives and rules on issues such as human rights protection, labor standards, environment standards, and anti-corruption requirements. It is mandatory that all CTCI suppliers— existing or new alike— obey such code of conduct. CTCI also encourages suppliers to ask their business partners to do the same. This collaborative effort across the industry chain will allow the whole industry to become more sustainable.

3. Sustainability Assessment for Supplier Selection While supplier code of conduct seeks to align supplier values with that of EPC company, supplier assessment for procurement decisions can incentivize suppliers to follow such code of conduct and bring positive impact. For example, when selecting critical equipment suppliers, CTCI uses equipment/subcontractor qualification assessment standard list to assess supplier´ qualifications. Criteria of assessment include: health (H), safety (S), environment (E) requirements, pricing, timeliness of delivery, country of origin, production site, port of origin, company integrity, and HSE management mechanism in place. Company integrity and HSE management mechanism are sustainability factors, which account for 10% of assessment score in CTCI´s supplier selection process. In determining company integrity, CTCI would look at a supplier´s past bidding history and terminate transaction with any supplier that has been involved in bribery, non-paying bids, bid-rigging, or threats. Prior to each tender decision, CTCI would again conduct one final discussion internally on the vendors whose bidding prices are close and pick the one whose performance in sustainability issues outperforms its counterpart. 4. Sustainability Risk Investigation and Assessment Suppliers pose various levels of operational and CSR risks to EPC companies. Determining the risk levels and taking appropriate actions to mitigate risks are critical. At CTCI, risk determination is a multi-faceted process. When a company registers to become potential supplier, the first step CTCI takes is to review its business permit, evidence of tax payment, company profile, track records, service or product quality, and HSE certification. Depending on where the supplier is located and the type of procurement, CTCI would then make visits to suppliers that come from certain areas (such as China and India). Such proactive risk assessment allows CTCI to better understand the risks involved. CTCI would also request all suppliers to self-evaluate by filling out standard questionnaires. This allows CTCI to identify the level of sustainability risks. For suppliers that have been determined as high-risk, CTCI would conduct further onsite audits and issue recommendations for improvement.

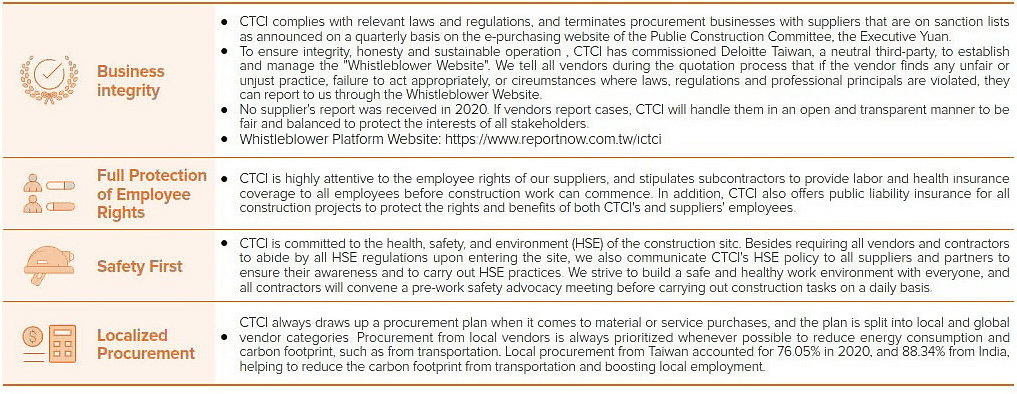

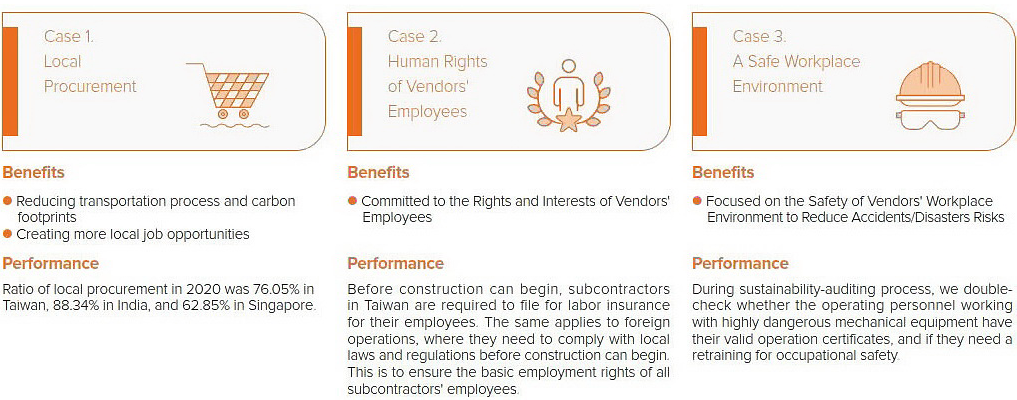

5. Raise supplier awareness on CSR through Supplier Meeting A good way to raise supplier awareness on CSR is to gather all suppliers together in a meeting and tell them what EPC company expect from them. Awarding suppliers for good performance can incentivize suppliers to keep improving. At CTCI, suppliers gather together at the biennial Supplier Meeting, where outstanding suppliers from pipeline, equipment, track works, electrical engineering, and labor services receive awards and are commended for their performance. CTCI is now planning to create a set of evaluation methods to pick out vendors with outstanding CSR performances, by types and by scale. CTCI will communicate such evaluation methods at the Supplier Meeting. If the suppliers fully cooperate with the improvement scheme, they will be given Vendor Award for CSR Excellence. 6. Form a sustainable supply chain strategy and engage suppliers Having a strategy in place is important to ensure a sustainable supply chain. CTCI values partnership with all suppliers and seeks continuous collaboration and growth. As such, CTCI has engaged suppliers in its strategy formation. The strategy has four elements: business integrity, full protection of employee rights, safety first, and localized procurement. In addition, a supplier platform and independent whistleblower platform improves fairness and communication.

7. Supplier evaluation Supplier performance evaluation is a critical component of sustainable supply chain management. It ensures that the products and services suppliers and subcontractors provide— such as equipment, engineering services, fabrication services, and construction services— meet the quality, HSE, pricing, and delivery schedule demands of the client of EPC company. At CTCI, evaluation on machinery and equipment suppliers is carried out as soon as an engineering project begins. When evaluating suppliers, project procurement managers and procurement engineers follow “Supplier and Subcontractor Evaluation Procedure” to ensure integrity and unbiased treatment. Suppliers who receive 8 points in both total evaluation score and HSE evaluation will receive letters of recognition. Suppliers who fail to pass evaluation will be reported for further punitive treatment, stripping their supplier rights. Their rights may only be restored upon internal review by relevant business departments.

Conclusion

These seven aspects allow an EPC company to build a supply chain management mechanism that is sustainable, fair, transparent, and always improving. CTCI has successfully raised suppliers’ awareness on corporate social responsibility. Working hand in hand with tens of thousands of suppliers, CTCI will continue to commit to providing clients sustainable, environmental-friendly engineering services.