Technology

技術分享

Application of Air Conditioning Technologies in Lithium-ion Battery Factories

—Ming-Fu Wu, Engineer at CTCI Smart Engineering Corp., Group Intelligent Solutions Business

With the rapid growth of the global technology industry, there has been a continuous rise in the demand for computers, communication, and consumer electronics products. As the primary power source for these products, lithium-ion batteries play a critical role. However, lithium-ion batteries are extremely prone to contamination during the production process. Pollutants in the form of airborne dust, metal particles, and moisture may lead to severe defects in the finished products, even triggering combustion or explosion. In response, lithium-ion battery producers must not only continuously advance their technical capabilities to ensure product quality but also meet the increasingly stringent process conditions within the production environment. To rigorously control cleanliness and humidity levels, three critical parameters stand out, which are dust, metallic particulates, and moisture. Establishing a dry and particle-free environment that meets the demands of advanced production processes within a very short timeframe remains the greatest challenge faced by engineering teams. This article specifically highlights how CTCI Smart Engineering Corporation (CTCI SEC), a CTCI Group company belonging to the Group Intelligent Solutions Business, leverages air conditioning technology design and application to meet the ultra-low humidity and stringent cleanliness requirements of the lithium-ion battery production processes, which in turn helped its clients boost product yield, improve production efficiency, and achieve greater operational safety.

Production Process of Lithium-ion Batteries

The production of lithium-ion battery involves three production areas: electrode production, assembly, and formation. Each production area serves different functions, yet collectively they form a complete lithium-ion battery production chain. 1.Electrode Production This production area is primarily about processing cathode and anode materials. Cathode materials (such as ternary materials or lithium iron phosphate) and anode materials (such as graphite) are respectively coated onto aluminum foil and copper foil. These coated foils then undergo drying, rolling, and slitting processes to form electrode sheets. Subsequently, the cathode and anode sheets are combined with a separator and wound to form the initial structure of the battery cell. 2.Assembly After winding, the battery cells are inserted into metal casings, followed by processes such as tab welding, electrolyte filling, sealing, cleaning, and film lamination, ultimately forming complete battery cells. At this stage, dust control and explosion prevention design are particularly critical, especially during the handling of electrolytes, which requires meticulous care. 3.Formation The sealed batteries undergo the initial charge-discharge process known as formation. This procedure is conducted at low current to activate the cells and stabilize the internal chemical reactions. Typically lasting several days, the formation process requires a controlled and stable temperature environment.

Production Process of Lithium Batteries

Application of Air Conditioning System Technology in Lithium Battery Production

To keep the production environment clean and maintain stable humidity levels, lithium-ion battery production relies heavily on high-precision air conditioning control systems. In particular, in the electrode sheet-making and assembly areas, trace amounts of moisture and metallic particulates can cause battery short circuits or quality defects, severely impacting production yield and product safety.

1.Air Conditioning Technology for Electrode Sheet Production Area

Since the processing of cathode materials requires an extremely dry environment with dew point temperatures ranging from -30°C to -50°C, a high-performance dehumidification air conditioning system must be established. Here, we share an example case that adopts a two-stage dehumidification system combining a make-up air unit (MAU) and an air handling unit (AHU), taking both cost and efficiency into consideration.

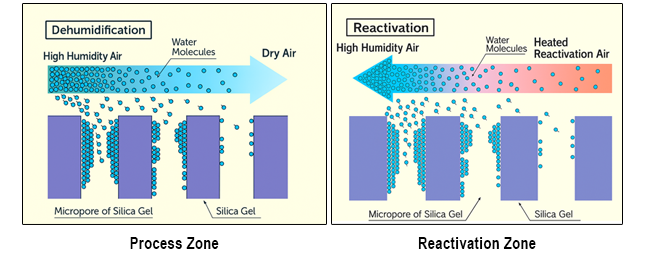

.Stage One: Chemical Rotor Dehumidification MAU (DH-MAU)

In this stage, a chemical rotor utilizing silica gel is employed to perform chemical dehumidification on the incoming fresh outdoor air, reducing the dew point to approximately -20°C (this is only a reference value; MAU systems can be designed to achieve dew point temperatures as low as -60°C. It is recommended to determine the optimal supply air dew point and energy consumption based on local climate analysis). Additionally, a heat recovery mechanism is in place by regenerating high-temperature wind to enhance energy efficiency.

.Stage Two: Chemical Rotor Recirculation Air Handling Unit (DH AHU) After mixing again with indoor return air, the air undergoes a second stage of deep dehumidification via a molecular sieve dehumidification rotor, further reducing the dew point to below -60°C to ensure that the indoor humidity remains at an ultra-low level. In addition, the system must be equipped with an ultra-low dew point sensor and an air volume control system to enable real-time monitoring and stable air supply, thereby ensuring that the dryness and cleanliness of the production environment meet required standards. This is further supported by ultra-low dew point temperature sensors for real-time regulation of airflow to maintain a stable environment.

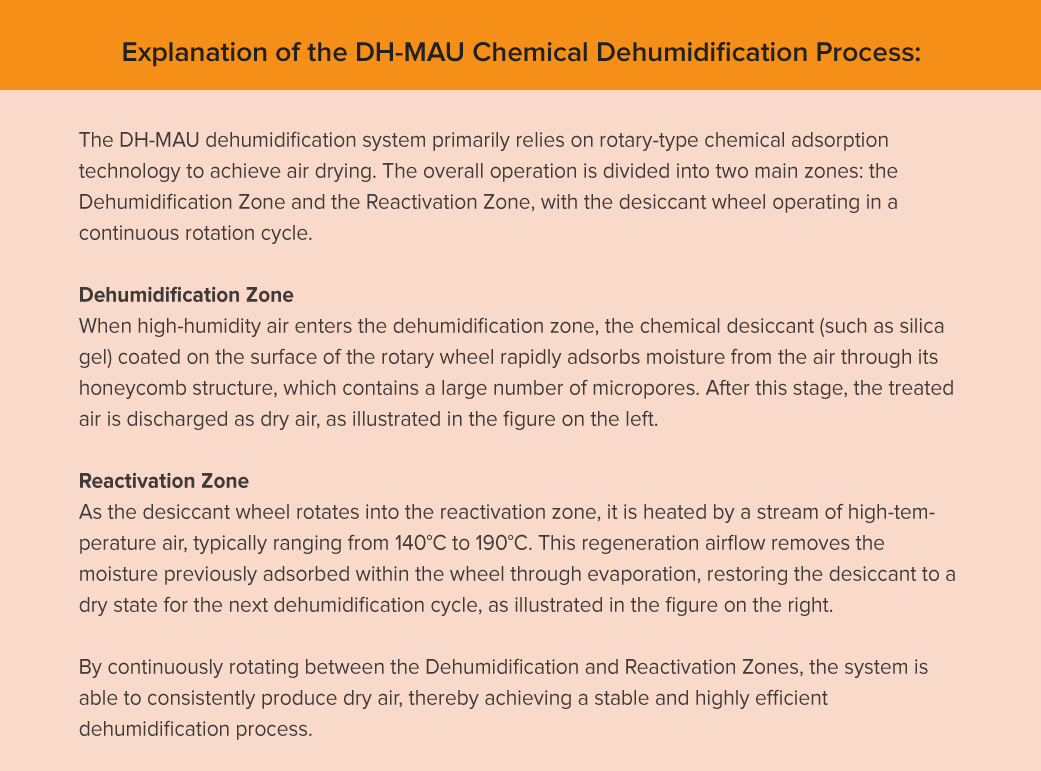

Operational Process of the Chemical Dehumidification Rotor

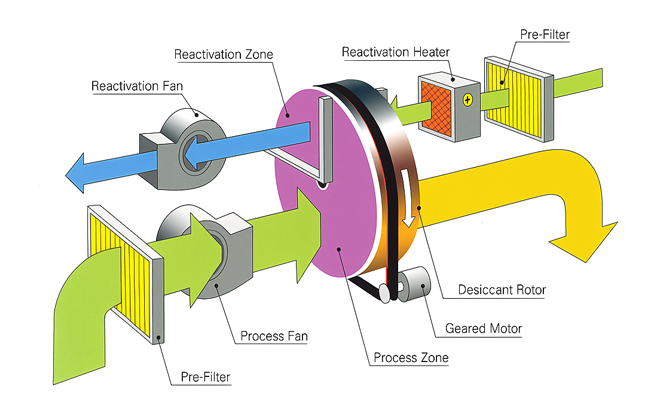

In the dehumidifying air handling unit (DH-AHU), CTCI Group has implemented an energy-saving design by introducing an additional ''energy-saving zone'' at the downstream section of the desiccant wheel (as shown in the figure below). This zone is positioned immediately after the high-temperature reactivation zone, where the desiccant surface remains at elevated temperatures. By diverting a portion of the AHU's exhaust air to bypass into the energy-saving zone, the residual heat from the wheel can be recovered and redirected to the reactivation zone, thereby reducing the required heating load. Furthermore, this thermal energy recovery mechanism allows the desiccant wheel to be pre-cooled before entering the dehumidification zone, effectively lowering its surface temperature. As a result, the subsequent DH-AHU system requires less chilled water for cooling, thus reducing the energy consumption of the chilled water coil. This energy-saving design not only decreases the heat demand in the reactivation zone but also reduces the cooling capacity needed to maintain indoor temperature, thereby improving overall system energy efficiency and achieving dual energy-saving benefits.

Energy-Saving Plan for Desiccant Wheel Dehumidification Systems

2.Control of Dust and Metal Particulates Mechanical operations such as rolling, slitting, and winding in the electrode sheet processing area often generate substantial amounts of fine dust and metal shavings. To reduce the risk of contamination, extend equipment lifespan, and ensure operator safety, supplementary systems should be implemented. These include HEPA-grade air filtration systems, dust extraction equipment, vacuum cleaning systems, and enclosure designs for process equipment. Such measures help prevent particulate ingress into the electrode sheets, thereby avoiding the introduction of conductive foreign materials that could degrade battery performance or pose potential safety hazards. 3.Air Conditioning Technology for Assembly Area The assembly area involves electrolyte filling and cell sealing, during which the electrolyte characterized by its high volatility and flammability, necessitates stringent environmental safety measures. Accordingly, in addition to maintaining controlled humidity and cleanliness, the air conditioning system should also incorporate the following functionalities: .Mini-environment control: It enables localized regulation of humidity and cleanliness levels to enhance management efficiency and energy-saving performance; .Ventilation system design: This prevents the accumulation of electrolyte vapors and enhances air circulation; .Explosion-proof and fire prevention mechanisms: This includes the installation of smoke detectors, explosion-proof lighting fixtures, and emergency exhaust systems. In the case study shared above, the mini-environment adopts a fully enclosed, full-coverage configuration, which enables more effective control over production humidity, cleanliness, and safety. 4.Air Conditioning Technology for Formation Area Prior to entering the formation area, the batteries have undergone cap-sealing and cleaning processes; therefore, airborne particulates no longer impact battery quality. This stage marks the initial charge-discharge cycle of lithium cells, during which the cells generate heat. Consequently, the primary objective of the air conditioning system is to maintain stable temperature control, typically within a tolerance range of ±2°C to ±3°C. Taking CTCI Group’s engineering project in 2023 for Molie Quantum Energy Corp.’s lithium-ion battery factory as an example, the air conditioning system was optimized based on the heat dissipation characteristics of the cells, including: Increased air supply volume to enhance heat exchange efficiency; and temperature range control to ensure stability of the charge-discharge reactions.

Trends and Outlook in Lithium-ion Battery Engineering

Taiwan is located in a humid subtropical climate zone, while lithium-ion battery production requires extremely stringent conditions of dryness and cleanliness. Therefore, in designing air conditioning systems for lithium-ion battery production facilities, it is essential to place greater emphasis on balancing energy efficiency and environmental sustainability. In the current market for lithium-ion battery production, a range of innovative air conditioning technologies are being progressively adopted, including high-efficiency rotary dehumidification modules, regenerative heat recovery systems, and intelligent control platforms with real-time energy monitoring. These technologies not only effectively reduce energy consumption associated with air conditioning, but also support factories in obtaining international certifications such as the LEED Green Building Certification, thereby enhancing corporate image and global competitiveness. The air conditioning technologies discussed in this article was successfully applied in 2023 at Molie Quantum Energy Corp.’s newly constructed lithium-ion battery production facility in Taiwan. This project demonstrated high innovation and integration in energy-saving design by ceramic bearing chillers, a variable primary flow chilled water system, and a full outdoor air natural cooling mechanism during winter. Additionally, it integrated process heat exhaust systems for thermal energy recovery, significantly enhancing overall energy efficiency. This comprehensive approach earned the project the LEED Gold certification for green building, demonstrating stable and highly efficient environmental control capabilities. This not only ensured production yield and product quality but also contributed to achieving energy conservation and carbon emissions reduction goals. As the lithium-ion battery industry continues to grow and environmental regulations become increasingly stringent, air conditioning systems will no longer serve merely as part of basic infrastructure, but rather as a critical enabler for enhancing product value and promoting sustainable development for enterprises. Looking ahead, CTCI Group will continue to integrate and apply advanced technologies, working closely with clients to develop smarter, more stable, and energy-efficient lithium-ion battery production environments.