Discover Reliable

發現信賴

CTCI’s Safe and Innovative Solution in Waste Treatment: Introducing the ECOVE SRC Waste Solvent Purification and Recovery Service

—Jason Su, President of ECOVE Solvent Recycling Corp., Group Resource Cycling Business

- Market category: Recycling and reuse

- Service location: ECOVE Solvent Recycling Corp.’s Guanyin Plant

- Reuse institution: ECOVE Solvent Recycling Corp., CTCI Group

- Operator: ECOVE Environment Services Corporation, CTCI Group

- Completion date: 2018

- Business scope: Collection, transportation, recovery, treatment, and sale of waste solvent

Since its establishment in 2018, ECOVE Solvent Recycling Corp. (ECOVE SRC)—a part of CTCI’s Group Resource Cycling Business—has focused on the recovery, purification, and reuse of waste solvents generated by the high-tech industry, which constitute a major part of the company’s business. As waste solvents significantly increased in amount due to the booming high-tech industry, ECOVE SRC has been actively advancing and integrating technology to help clients purify low-concentration waste solvents into higher-concentration product for resale. ECOVE SRC also supports clients in introducing waste solvent treatment facilities to their own sites according to their needs, and incorporates waste heat recovery into the production process. Through these mutually beneficial efforts with the clients, ECOVE SRC is contributing to the green economy and sustainable production. Today, ECOVE SRC can produce isopropyl alcohol (IPA) with concentration level of 99.95% that meets electronic-grade specifications. Moreover, to meet the net zero emissions targets, the company has achieved full plant carbon neutrality and continues to reduce carbon emissions of its production processes by conducting comprehensive greenhouse gas inventories, thereby advancing low-carbon production and practicing green manufacturing.

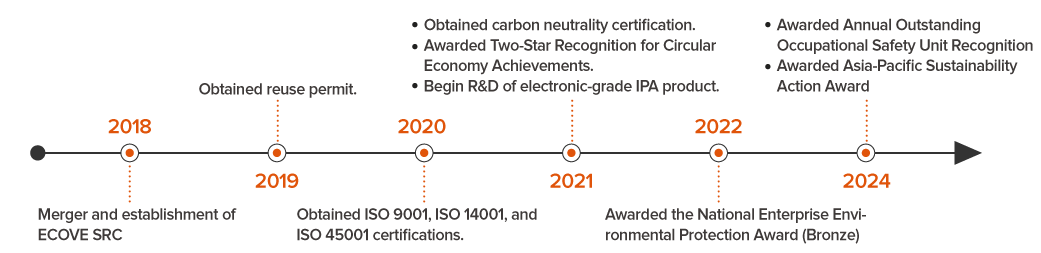

ECOVE SRC’s milestones

ECOVE SRC’s Guanyin Plant processing area (left) and plant exterior (right)

Why CTCI?

Integrated Technologies for High-Efficiency Recovery

CTCI Group has been deeply engaged in the field of waste management for over thirty years, with in-depth knowledge of various waste characteristics and treatment processes. It continues to optimize processing efficiency and management quality by incorporating intelligent control systems and data management technologies. As a Group affiliate company, ECOVE SRC combines its expertise in incineration, green energy, recycling and reuse, and electromechanical operations and maintenance, allowing it to enhance the waste solvent recovery efficiency by systematically optimizing the distillation equipment, as well as track waste flows and treatment status in real time. The solutions that ECOVE SRC provide to its clients are stable and efficient, a key to maintaining sustainable operations.

Reliable Realized

Fostering a Culture of Safety with a Zero-Accident Record

In the process of purifying waste solvents, operational risks must be taken seriously, especially when handling high-concentration chemical substances. Any misstep may result in significant safety hazards. ECOVE SRC adheres to the principle of "Safety as Top Priority," rigorously implementing a risk management system that begins at the source, ensuring stable operations and a safe working environment. Since its establishment in 2018, there have been no occupational safety incidents, a testament to the company's rigorous risk management system. ECOVE SRC enforces strict risk management at every stage—before, during, and after operations. This includes pre-operation safety inspections and hazard notifications, real-time reminders, a three-tier inspection system during operations, as well as post-operation reviews and improvements. Through the implementation of standard operating procedures (SOPs), walk-arounds by on-site supervisors, and joint safety inspections, a comprehensive foundation for a proactive, fully engaged safety culture may be established. The Company also actively promotes first-aid training, ensuring that all employees are certified in CPR and AED operation. The Company itself has also been certified as a “CPR + AED Safe Facility,” an effort in strengthening its emergency response capabilities. Daily morning safety briefings and case studies help foster a strong sense of teamwork and risk awareness across the organization.

Rigorous HSE System, Embedding a Culture of Safety

ECOVE SRC has established a rigorous and reliable Heath, Safety, and Environment (HSE) system, as well as implemented the internationally recognized ISO 45001 Occupational Health and Safety Management System. Various safety management practices are in place to ensure effective risk identification and operational control. Operations identified as high-risk follow the "three-party joint Lockout-Tagout (LOTO)" procedure, which requires the operating supervisor, the safety and health supervisor, and the maintenance personnel to jointly verify that the equipment has been powered off, isolated, and tagged before any work begins. Additionally, the plant managers and the HSE management personnel conduct spot checks and comparisons during the on-site operations to ensure that no detail is overlooked, thereby safeguarding operational safety.

Three-Party Joint Lockout-Tagout (LOTO)

To strengthen contractor management, all contractors are required to undergo hazard communication, safety coordination meetings, and toolbox meetings before entering the facility. All equipment and machinery brought onsite are inspected prior to use to ensure safety. During operations, daily toolbox meetings are held, and joint HSE audits are conducted from time to time. If any non-compliance is detected, work is immediately halted, a toolbox meeting is convened for review, and operations may only resume after corrective actions are completed. For more than six years since its establishment, ECOVE SRC has maintained strict safeguards at every stage and achieved zero safety incident record. This reflects the team’s strong commitment to occupational safety from the top management down to the frontline. Their efforts have successfully created a reliable and safe working environment. In recognition of these achievements and comprehensive safety practices, ECOVE SRC was honored with the "Outstanding Occupational Safety Unit" in 2024, an acknowledgment of excellence in fostering a safety culture and proactive risk management.

Contractor pre-entry hazard communication(left); joint HSE inspection (right)

Outstanding Occupational Safety Unit Recognition

Project Highlights

Adopting Innovative Technologies to Enhance Efficiency and Reduce Risk

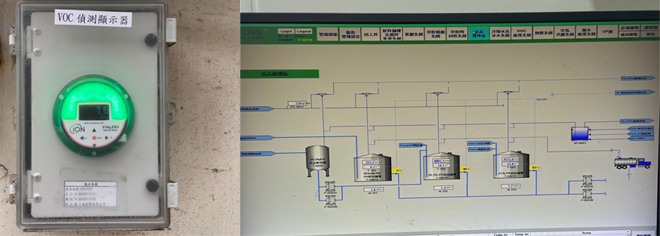

In addition to pursuing safe and stable operations, ECOVE SRC spares no effort in adopting innovative technologies to enhance process efficiency and risk protection. By implementing the proprietary Maintenance Management Information System (MMIS), the Company can monitor equipment status and maintenance records in real time, which helps reduce the risk of unexpected failures as well as enhance equipment stability and operational safety. In 2024, ECOVE SRC achieved further breakthroughs in volatile organic compound (VOC) monitoring by adding a VOC detection system that transmits real-time monitoring data to the central control room. This allows the control room personnel to continuously monitor piping leakage conditions, enabling full-process real-time monitoring and risk alerts. In the same year, the Company also introduced smart panel technology and upgraded the switching operation of the IPA stock in storage tanks from manual to semi-automatic control, effectively reducing workers’ exposure to high-risk operating environments.

VOC monitoring

Semi-automatic operation for product tank switching

Innovative Technology

Driving Green Transformation Through Technical Advancements

In addition to establishing an uncompromising safety protection network in occupational safety, ECOVE SRC also insists on continuous improvement, proactive innovation, and pursuit of excellence in increasing the product value and its market competitiveness through upgrades in technology. The company has long been successful in purifying waste IPA generated by the semiconductor industry into industrial-grade IPA at concentrations of 85% and 99.5%, which were then reintroduced to the market. Subsequently, the company adopted vapor permeation technology and successfully reduced product moisture content to below 1,000 ppm and increasing industrial-grade IPA concentration to 99.9%, while significantly lowering energy consumption. For such outstanding achievements in high-value recovery, energy conservation, and carbon reduction, ECOVE SRC was honored with the Gold Award for SDG 12: Responsible Consumption and Production at the 2024 Asia-Pacific Sustainability Action Awards. The award represents major recognition on the company’s long-standing efforts in promoting circular economy and environmental sustainability.

Asia-Pacific Sustainability Action Awards

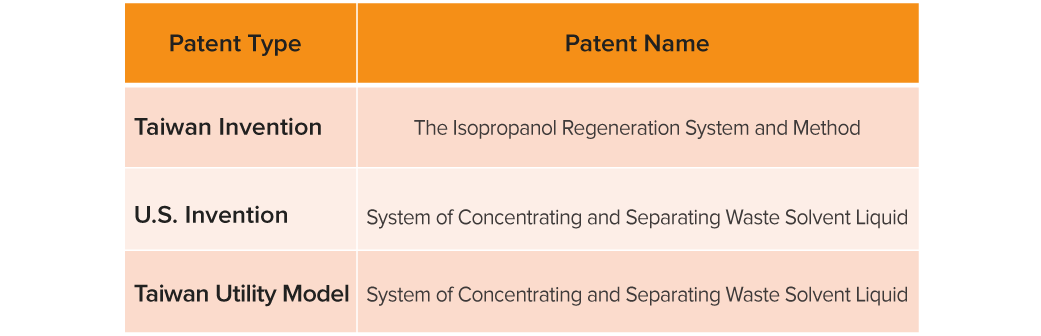

In its rigorous R&D journey, ECOVE SRC has obtained multiple patents in Taiwan and the United States for purification and separation integration systems (see table below). In combination with eight types of process technologies, waste solvents of varying concentration levels can be recovered as new products with varying specifications. The Company’s evaporation and permeation technology, which utilizes molecular sieve inorganic membrane tubes as membrane materials, enables precise separation of IPA and water molecules. The process can be flexibly adjusted to handle waste IPA of various concentrations.

Waste Solvent-Related Patents Obtained by ECOVE SRC

In recent years, ECOVE SRC has not only been developing electronic-grade IPA, which is technically more challenging, but also exploring new business models. The idea is to help semiconductor clients set up in-house waste IPA concentration facilities for preliminary concentration. Once high-concentration waste IPA is generated, it is sent to ECOVE SRC for further concentration before becoming final, reusable product. There have been multiple successful cases so far, with promising business outlook. ECOVE SRC will continue to enhance its recovery expertise and, by offering the “Most Reliable” services, work with its clients to achieve a sustainable future that is characterized as green economy and sustainable production.

Message from the Management Team

With a commitment in environmental protection and circular economy, ECOVE SRC has been advancing recovery technologies and helping its clients to establish on-site concentration facilities to improve recovery efficiency. The project was successfully completed under the professional support and safety management of the ECOVE team. The operation team will next take over and provide stable and safe operational services to achieve green processes and sustainable production goals.