Technology

技術分享

Operator Training Simulation for LNG Terminal

— Paweena Phajonphai, Senior Instrument Engineer, CTCI Thailand, Group Engineering Business

For many years, CTCI Group has built high-quality liquefied natural gas (LNG) receiving terminals in Taiwan, Thailand, China, and India by leveraging its “Most Reliable” engineering, procurement, and construction (EPC) capabilities. To support operator training during the commissioning and start-up stages in an LNG terminal, CTCI introduced a customizable Operator Training Simulation (OTS) system to reflect the project’s actual process design and enable operators to practice real-scenario responses. In this article, we will talk about the OTS in detail.

LNG Terminal Operation Simulation and Training with OTS

LNG terminals are a vital part of the global energy network. They handle the critical tasks of receiving, storing, regasifying, and delivering natural gas to consumers. Operating these facilities means working with cryogenic fluids, high-pressure systems, complex control networks, and strict safety protocols—all of which demand a skilled and confident workforce. To allow operators practice essential procedures—from start-ups and shutdowns to system line-ups and emergency handling—without putting people or assets at risk, an OTS is a useful training tool. It is a computer-based dynamic simulation that mirrors the real behavior of an LNG terminal, reproducing physical processes, control logic, instrumentation, and alarm responses in a realistic virtual environment. Unlike traditional classroom learning, OTS-based training is hands-on and immersive. Trainees engage directly with the same HMI screens, control systems, and field logic they use in the real plant. The result is deeper understanding, stronger confidence, and safer, more effective operations. Simulation enhances team coordination, allowing control room operators and field staff to practice procedures together and clarify their roles—especially during shift handovers and critical operating phases such as cold starts, high boil-off gas (BOG) loads, or send-out ramping.

OTS Infrastructure and Architecture

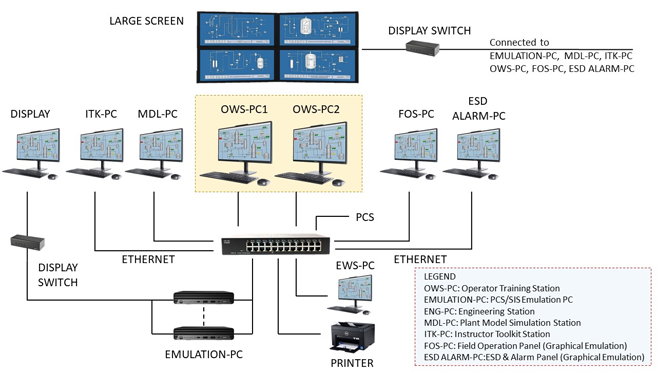

An OTS for an LNG terminal isn’t just about making a process simulation—it’s about recreating how the real plant actually thinks and reacts. To achieve that level of realism, the simulator must connect directly to the same engineering databases used by the Distributed Control System (DCS) and Safety Instrumented System (SIS). These contain all the critical logic—alarms, interlocks, and shutdown sequences—that define how the terminal operates safely and efficiently in both routine and emergency conditions. The OTS is developed from the latest DCS/SIS configuration data, creating a high-fidelity virtual replica of the actual control environment. Every scenario, from a standard start-up to a compressor trip, follows the same logic and timing as it would in real operations. To support this, the OTS is structured around several connected modules, each handling a key part of the simulation system. This includes Model Station (MDL), Instructor Workstation (ITF), Human Interface Station (HIS), Field Operated Device Station (FOS), Engineering Station (ENG), DCS/SIS Simulator Station (SIM), SIS Alarm Station, OTS Network and Data Storage, Large Screen System (Video Wall), and Printer and Logging System (Figure1).

OTS System Architecture

This modular setup allows the OTS to support a wide range of training applications—from individual skill development to team-based exercises. It can be used for fundamental operations, complex fault recovery, or even live demonstrations in classroom sessions. In essence, it goes beyond being a simulator; it functions as a comprehensive, full-scale training platform.

Core Competency Framework for LNG Operational Training

To strengthen operational excellence across the LNG Terminal, an OTS program is structured around five key competency domains. Each domain addresses real operational risks and responsibilities, ensuring that every training activity equips operators with the skills required to perform confidently and safely in the field. Process Safety Management The program reinforces the importance of early hazard recognition and decisive action. Operators practice identifying system deviations, navigating interlocks, and executing emergency procedures—instilling the principle that effective safety management begins with anticipation rather than reaction. Field Safety Practices and On-Site Operational Discipline Training extends beyond the control room to reflect the realities of on-site operations. Field operators engage in scenarios involving equipment trips, valve verification, and manual intervention. These exercises emphasize safe working distances, situational awareness, and efficient coordination during time-sensitive events. Environmental Stewardship in LNG Terminal Operations Environmental integrity is a core focus within the curriculum. Operators learn to manage boil-off gas, minimize flaring, and control waste streams. Practical scenarios such as managing transitions during send-out reductions or shutdown conditions help prevent unnecessary emissions and ensure alignment with regulatory requirements. Crisis Communication and Coordinated Emergency Response The OTS scenarios simulate high-stress situations where clear communication is essential. Trainees practice notifying operational teams, responding to warning systems, and coordinating with emergency and public safety personnel. Every step aligns with the terminal’s established emergency response plans, reinforcing consistent and effective communication. HSSE Documentation and Post-Scenario Incident Recording Following each exercise, operators complete digital incident records detailing their actions, timelines, and alarm acknowledgments. This process strengthens accountability, promotes traceable decision-making, and cultivates strong reporting habits that support HSSE compliance and audits.

Realistic Operational Scenarios for Operator Readiness

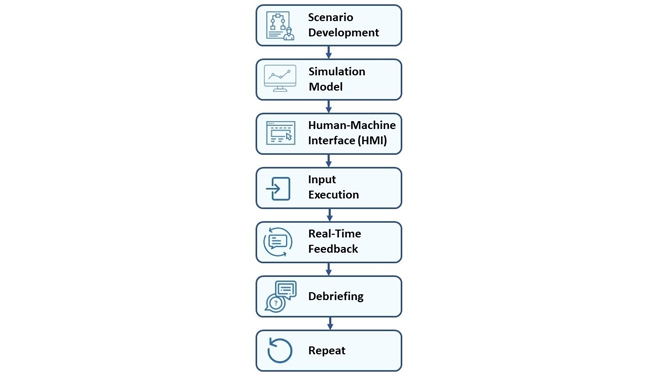

An OTS program adopts a fully scenario-based learning approach, ensuring that training reflects actual plant behavior rather than generic instruction. Since each module is built directly from live plant logic and authentic operating conditions, it enables operators to engage with realistic challenges similar to those they may encounter during operations. The modules are carefully designed with increasing levels of complexity, allowing operators to build confidence step by step. New personnel begin with foundational activities such as basic start-up sequences or routine tank line-ups. As they advance, the scenarios introduce more nuanced challenges—including gradual pressure deviations, unstable BOG compressor behavior, or low send-out transitions—requiring operators to interpret trends, analyze alarms, and take preventive action before conditions deteriorate. By practicing under realistic and evolving conditions, operators sharpen their reflexes, enhance communication across teams, and internalize critical procedures long before they are required to apply them in real operations. The simulator meticulously tracks trainee performance, including response time, alarm management, decision pathways, and system recovery actions. Control loop characteristics such as interlocks, time delays, and field feedback are faithfully modeled. Alarms function precisely as they do in the plant’s DCS, allowing trainees to strengthen their situational awareness, sharpen their reaction skills, and build consistent pattern recognition through repeated practice.

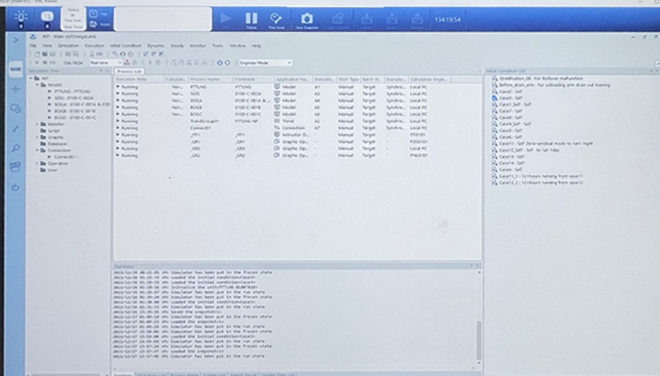

OTS Alarm and Trip simulator screen

OTS Instructor’s Control Console for Simulations

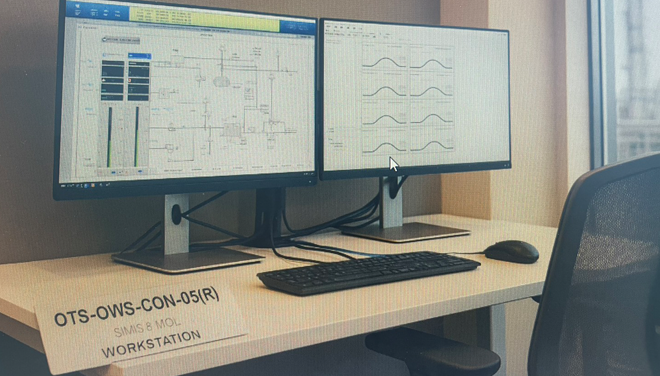

Trainee Participation Step in Simulator-Based Training

Stability Management During Holding Operations Mode

Among the various OTS training scenarios, Holding Mode is a stable yet essential environment where operators can refine the competencies that underpin safe and reliable LNG terminal operations. Holding Mode refers to the operational state where no LNG is being transferred to or from the storage tanks, but the terminal continues to process and send out regasified natural gas to the pipeline. Holding Mode is featured as the flagship OTS scenario because it reflects the terminal’s routine operating conditions. Unlike ship unloading, which occurs periodically, Holding Mode requires continuous management of tank pressure, BOG behavior, and system readiness. This makes it the most relevant and frequently practiced scenario for daily operations. Contrary to common perception that Holding Mode is a period of inactivity, it is in fact a highly controlled operating condition that requires continuous attention. Even when no LNG is entering or leaving the tanks, the entire system remains pressurized. Operators must closely monitor tank pressure and sustain recondenser circulation using LP LNG to absorb boil-off vapor. Without proper attention, issues such as compressor cycling, tank stratification, or alarm overload may arise. Maintaining the balance between tank pressure, temperature, and boil-off dynamics is essential, and the OTS brings this complexity to life by treating Holding Mode as a fully interactive training environment. Under Holding Mode, an OTS trainee would engage in key activities such as identifying gradual increases in tank pressure, adjusting recondenser load to match fluctuating LP LNG feed, handling compressor surge conditions or low-suction alarms, and completing periodic checklists to verify safety-critical systems. The simulation exercises help identify common operating errors during Holding Mode, such as overlooking pressure trends or failing to manage rising BOG load. They help strengthen operator situational awareness, improve responsiveness to control loop behavior, and build the confidence needed to take early corrective action.

Key Simulator Tasks Assigned to Trainees

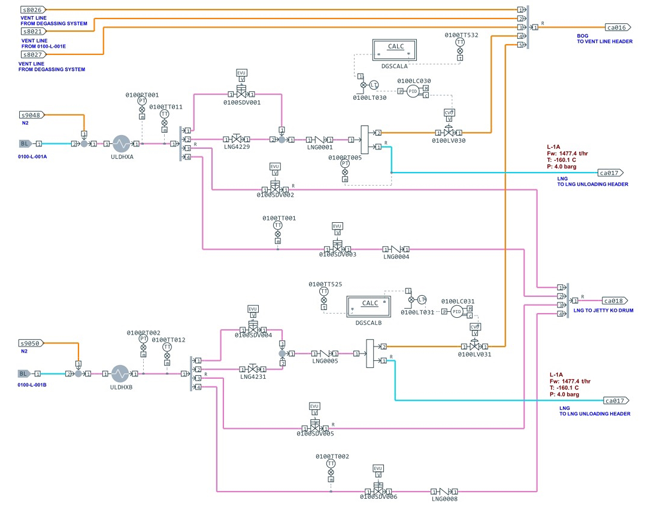

OTS scheme for an LNG Terminal

Maintaining Continuous Send-Out: Emergency Modeling for Shutdown Prevention

One of the LNG terminal’s critical operational targets is sustaining “No Zero Send-Out,” ensuring uninterrupted gas delivery even during equipment constraints or sudden reductions in demand. The OTS supports this objective by training operators through realistic, hands-on scenarios that mirror the challenges encountered in low-flow conditions. When send-out rates begin to fall, operators must act quickly to prevent tank pressure from rising. Key actions practiced within the simulation include: • Adjusting ORV/IFV vaporizer loading to maintain thermal balance • Engaging kickback loops to safeguard HP pumps from low-flow conditions • Shifting BOG compressors into low-load operation to stabilize suction pressure • Preparing the system for a rapid and controlled restart if conditions require These proactive responses are rehearsed repeatedly within the OTS environment, enabling operators to internalize the correct sequence of actions and develop the confidence needed to intervene before shutdown thresholds are reached. Each scenario concludes with a structured debriefing session, where timing, decision accuracy, and overall execution are analyzed to reinforce mastery under pressure.

Simulated Instructor-Controlled Scenarios: Strengthening Decision-Making in Holding Mode

Within Holding Mode, system stability is paramount. Instructors can replicate real operational challenges by triggering controlled disturbances for trainees. For example, excessive seawater flow to the ORVs during periods of low send-out can raise outlet vapor temperatures, disrupt control loop stability, and push pipeline pressure beyond safe limits—conditions that may ultimately lead to an unwanted shutdown. By experiencing these situations in a safe, simulated environment, operators learn to recognize early indicators and take decisive action to protect the “No Zero Send-Out” KPI before critical thresholds are reached.

Final Insights and Forward-Looking Perspectives

The OTS has evolved into a core element of operational readiness across modern LNG terminals. More than a training tool, it serves as a high-fidelity ecosystem that brings together process control logic, safety systems, and human performance into a unified, realistic learning experience. Looking forward, CTCI Group will pay attention to OTS’s technical progress and leverage OTS’s expanded capabilities through advanced technologies, such as digital twin integration, where live plant data is synchronized with simulation models to support predictive and scenario-based training; adoption of AI, which enables automated assessment and adaptive learning pathways; personalized learning tracks, tailoring scenario difficulty to individual operator performance; and immersive VR modules, which provides field-level simulations that enhance spatial awareness and equipment familiarity. By applying OTS in the LNG terminal projects more deeply, CTCI can bring greater value to its clients in terms of operation.