Discover Reliable

發現信賴

CTCI Helps FPC Stabilize Ethylene Supply:

FPC 14,000 Ton Cryogenic Ethylene Storage Tank EPC Project

— Luka Li, Project Management Department I, CTCI Beijing

- Market category:Hydrocarbon

- Owner:Formosa Industries (Ningbo) Co., Ltd. (FPC Ningbo)

- Execution: CTCI Beijing Co., Ltd.

- Completion date:Q4 of 2024

- Project location: Beilun District, Ningbo, Zhejiang Province, China

- Scope of work: Engineering, Procurement, Construction

- Capacity: 14,000 tons of ethylene storage

The client for this project is Formosa Industries (Ningbo) Co., Ltd., located in Beilun District, Ningbo City, Zhejiang Province, China, and serves as a key overseas production base for the Formosa Plastics Group. Ethylene is one of the most important basic raw materials in petrochemicals. Its stable supply contributes to the steady and high-capacity operation of downstream EVA (Ethylene-Vinyl Acetate) plant and PP (Polypropylene) plant. To enhance supply security, the client intends to build a 14,000-ton cryogenic ethylene storage tank and its auxiliary facilities on a reserved site within the terminal storage area. Once commissioned, the new tank will support the supply of cryogenic ethylene during the maintenance of the existing ethylene tank It will also be able to operate in coordination with the exist tank to prevent raw material supply interruptions, ensuring stable production of downstream plants. CTCI Beijing, a subsidiary of the CTCI Group, was awarded EPC contract of Inside Battery Limit (ISBL) and the engineering contract for the overall project in 2022. The project achieved mechanical completion in December 2024 and received high praise for its outstanding quality, recognized as “Most Reliable”.

Why CTCI?

Extensive Experience in Cryogenic Storage Tank Design and Construction

Since the early stages of investment and construction at FPC’s Ningbo plant, CTCI Beijing has been involved in the detailed design of multiple projects, and earning long-term trust through its exceptional design quality. In the market of cryogenic storage tank projects, CTCI Beijing has long collaborated with IHI Plant Services Corporation(IPC), a subsidiary of Japan’s IHI Group. In recent years, CTCI Beijing has successfully completed several cryogenic tank projects across mainland China. Notably, in 2021, the company completed the construction of two 93,000-ton propane tanks for FPC Ningbo—setting a record for the largest propane storage capacity in China. With this ethylene tank project, CTCI Beijing once again stood out for its extensive experience and technical expertise.

Groundbreaking Ceremony for the Project

Reliable Realized

Outstanding EPC Schedule Management

This EPC project involves several teams, with responsibilities that at times overlap or lack clear definition. Such ambiguity can lead to problems such as increased cost , schedule delays, and compromised quality. To prevent these challenges, CTCI Beijing implemented a detailed interface management plan. This included identifying key project interface points and assigning clear responsibilities, ensuring smooth communication and coordination. Adhering to the principle of a single-point interface with the client, CTCI Beijing facilitates accurate and timely information exchange. Regular coordination meetings were held to promptly resolve issues , enhance project management efficiency, and strengthen client trust.

Effective Integration of Government Approvals and Project Scheduling

CTCI Beijing fully understands that progress of government approval is a critical factor in EPC project management, with the potential to significantly impact the overall schedule. By the extensive project execution experience, CTCI Beijing actively engaged with relevant government authorities to gain a thorough understanding of approval procedures and required documentation. A detailed approval plan was then developed in alignment with the overall project schedule. With close cooperation between the design and construction teams, required documents were submitted and permits were obtained on time, ensuring that project progress remained unaffected by approval delays.

Project Highlights

Prestressed Concrete Full-Containment Tank Design

This cryogenic ethylene storage tank features a full containment design with prestressed concrete (PC Wall Full Containment Tank). The inner tank is made of 304 stainless steels, and the outer tank is prestressed concrete (PC Wall) with a liner plate. Thermal corner protection is installed in the annular space to prevents direct contact of cryogenic ethylene condensate with outer tank and base slab in the event of a leakage due to operational errors, effectively enhancing durability. With a storage temperature of -104°C and a BOG rate of 0.08wt%/day, advanced insulation materials—including perlite, resilient blankets, fiberglass wool, and cellular glass—were applied to minimize BOG loss. Due to the complex and irreversible construction steps of PC wall tank construction, a high standard of design and execution quality is essential. On the design aspect, the tank was designed by the IPC team, with a detailed plan to minimize material waste and ensure fabrication accuracy. This includes precise layoutdrawings for each rebar and cutting plan for every steel plate. On the construction aspect, due to irreversible construction steps of prestressed tank, quality of each step was strictly controlled by CTCI Beijing: 1.Strict quality checks on materials before construction to ensure compliance with design specifications. 2.Standardized operations during construction, with key parameters like concrete pouring temperature and WPS(Welding Procedure Specification), etc. 3.Strict inspections after each construction step, e.g. for inspection of weld seam radiographic testing(RT), penetrant testing(PT) and vacuum box testing(VT) was conducted to ensure weld quality.

Innovative Technology

Establishing a Measurement System to Support Roof Air Lifting Operation

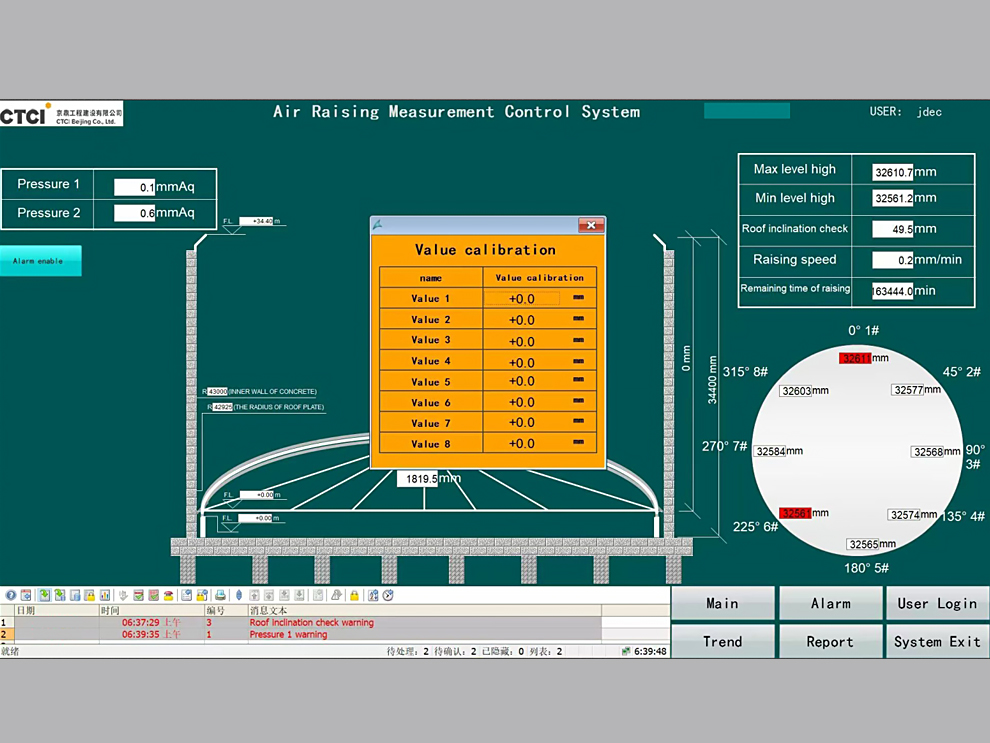

Roof Air Lifting is a critical step in tank construction. Due to its complexity and risks, CTCI Beijing adopt a balancing wire system to stabilize the tank roof during lifting and prevent roof offset or inclination. During the lifting process, the team continuously monitored dome elevation and tilt to allow real-time adjustments of vent openings and counterweights, ensuring proper control. The tradition method for air raising measurement, is use multiple measuring teams with tape measures at various points, reporting heights every two minutes via transceivers. A recorder would input data into a spreadsheet and calculate lifting speed and tilt rate by formulas. However, this method has some disadvantages like poor accuracy and time delay. To improve measurement method, CTCI Beijing introduced a Roof Air Lifting Measurement System as supplement to traditional method. The system includes a programmable logic controller(PLC), control station, laser rangefinders, pressure transmitters, and communication modules. By adopting laser distance measurement technology, real-time data on roof height variations was captured, allowing for accurate, real-time monitoring of lift speed and tilt rate. This innovative solution significantly improved operational precision and supported timely, informed decision-making on site.

Message from the Owner

“The CTCI team demonstrated international-level expertise and achieved mechanical completion on schedule, solidifying its reputation as a reliable partner.” -Project Manager, FPC Ningbo 14,000-Ton Ethylene Storage Tank Project