Discover Reliable

發現信賴

CTCI Successfully Constructs Cleanroom Facilities for Gas Supply Equipment: Merck SAFC Hitech Taiwan Co. Phase 2 Expansion Project

— Peter Lee, Project Manager at CTCI REI, part of the Group Intelligent Solutions Business

- Market Category: High-tech manufacturing facility

- Owner:Merck SAFC Hitech Taiwan Co.

- User Unit: Versum Materials Technology, Merck Group

- Execution:CTCI Resources Engineering Inc. (CTCI REI)

- Completion date: December 2022

- Project location: Kaohsiung Science Park, Kaohsiung City (Luzhu)

- Scope of work: Construction of a production and administrative building and cleanrooms

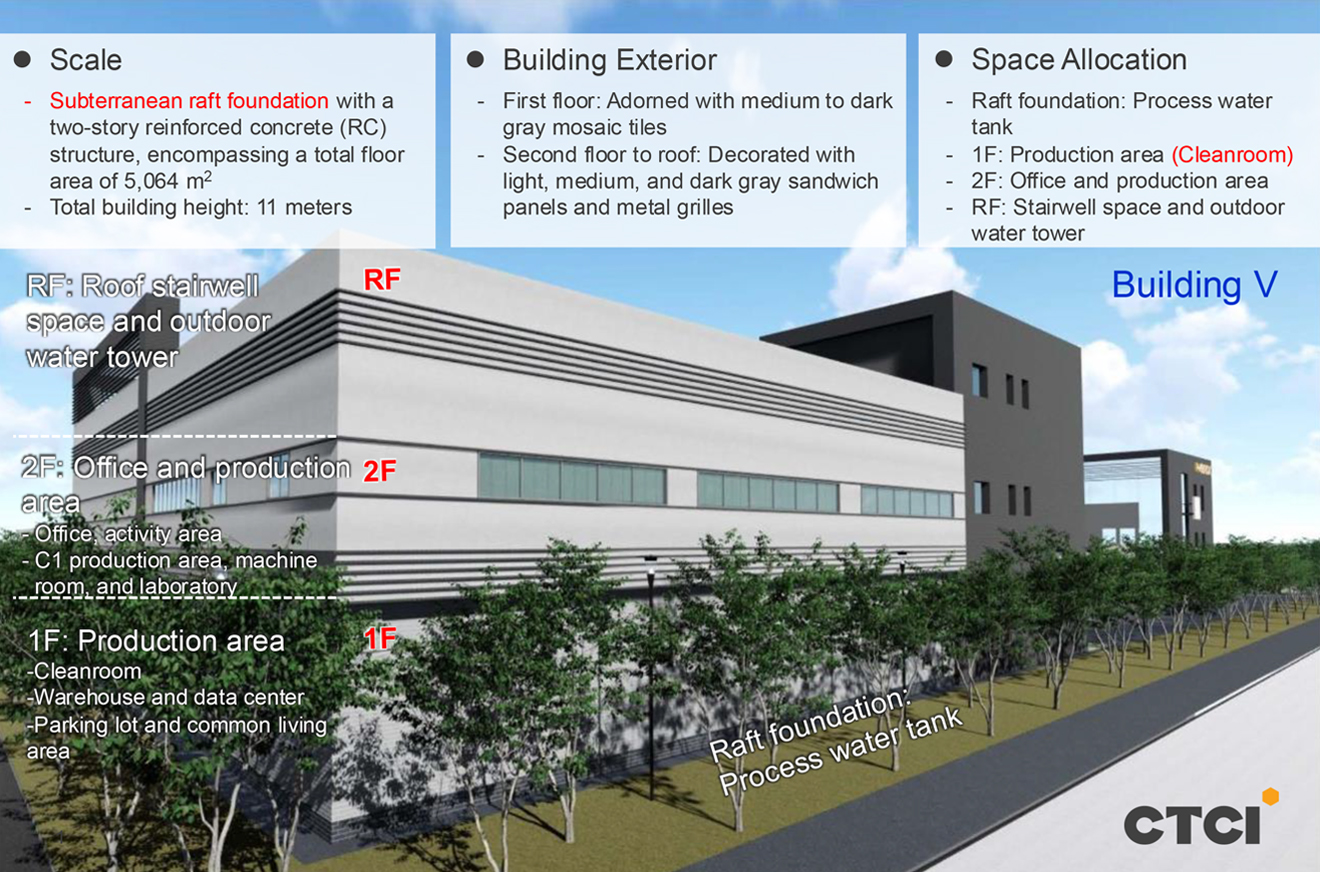

The client for this project is Merck Group's SAFC Hitech Taiwan Co., who had commissioned the construction of a new production and administrative building with the purpose of producing gas supply equipment at its Production Complex I in Kaohsiung. The gas supply equipment produced by this plant primarily serves the semiconductor manufacturing industry, with clients located worldwide, making this a highly significant project. CTCI Resources Engineering Inc. (CTCI REI), a part of CTCI’s Group Intelligent Solutions Business, is responsible for constructing the building structure and cleanrooms for this project. This encompasses the main office building (Building V), the outdoor parking lot (Building P), and the hazardous materials storage warehouse (Building O). The main office building features a basement raft foundation and is a two-story RC structure with grey-toned sandwich panels for the exterior walls. The interior space layout includes process water tanks in the basement; three cleanroom production facilities of Class 100, Class 1000, and Class 10000 on the first floor; and offices and factory facilities on the second floor. The main challenge of this project was the short construction period. However, the CTCI REI team, with a mission-driven spirit and proper pre-planning, successfully completed and launched the factory and administrative office within the client's required timeframe. This helped the client achieve an important milestone in business expansion, allowing them to seize the opportunity of increased semiconductor demand. As a result, such excellent execution received high praise from the client.

Description of the Scale of Main Building V

Why Choose CTCI

Professional Engineering Team with Outstanding Technical Expertise and Performance

As part of CTCI Group, CTCI REI is a leading contractor in Taiwan's public works sector. Over the years, it has undertaken various major public infrastructure and private engineering projects in Taiwan. The company has extensive experience in multiple fields including architecture, transportation, geotechnical engineering, shield tunneling, hydraulic engineering, environmental engineering, electrical engineering, and land development. It has received numerous awards and recognition, including the Construction Golden Safety Award, the Public Construction Commission Golden Quality Award, and the FIABCI-Taiwan Real Estate Excellence Awards. With its excellent contract performance, CTCI REI has earned high praise from its clients.

Our Reliable Team

Overcoming Challenges Associated with Short Construction Periods: Designated by Clients as the Most Reliable Partner

In response to the surge in global semiconductor demand and increased equipment production needs, Merck Group needed to urgently find a reliable contractor to build a new factory, which is part of the Phase 2 expansion project at the Kaohsiung Production Complex I. Due to the extremely tight schedule, many contractors were unwilling to take on the project. CTCI REI proposed a sectional construction approach during their quotation presentation to reduce construction time and meet targets, winning the client's trust and the contract over the client's usual contractors. Throughout the construction process, CTCI REI prioritized the client's needs, fully accommodating their requirements and changes, successfully completing the mission and earning the client's recognition and trust. Due to the excellent performance in this project, CTCI REI was subsequently designated as the CSA (Construction Service Agreement) EPC contractor for the Merck Kaohsiung Luzhu plant project.

Project Highlights

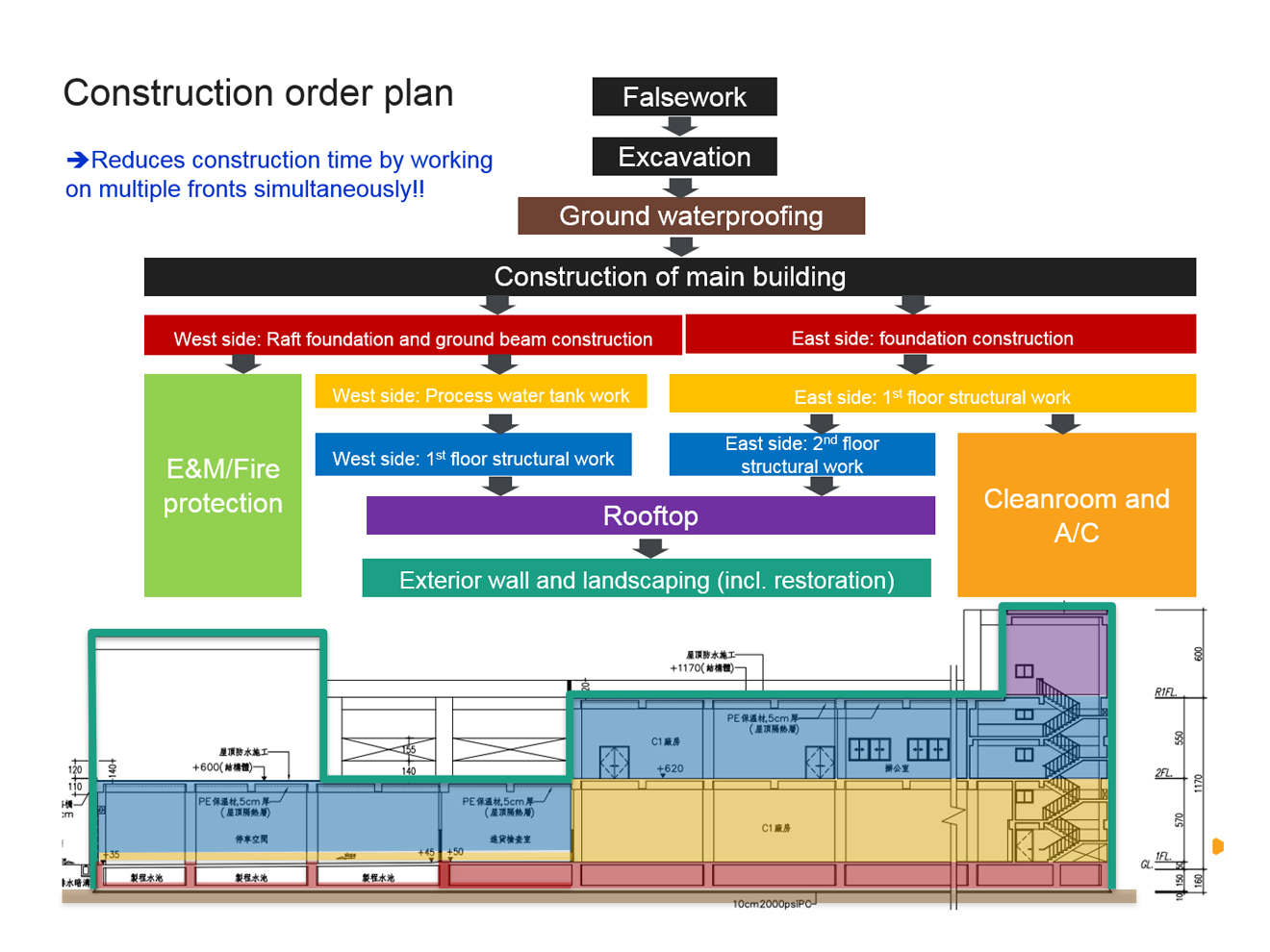

Zone-Synchronized Construction to Complete Tasks on Schedule

To accommodate the client's production schedule and complete the cleanroom construction ahead of time, so that the client's production equipment could move in, CTCI REI adopted a sectional construction approach, which involves dividing the building into east and west zones for simultaneous construction. The west zone consists of parking facilities and underground water tanks, while the east zone contains the cleanroom and office spaces. Considering the longer construction schedule required for the underground water tanks, the east zone's foundation used concrete backfill to directly proceed with the first-floor structural work, allowing simultaneous construction with the western water tanks, significantly reducing the project execution timeline. Furthermore, high early strength concrete was used, which reduced the formwork removal time by 14 days, allowing the subsequent first-floor cleanroom construction in the east zone to begin earlier. During the project's peak period, while the cleanroom was undergoing air volume adjustment, and while construction works were proceeding with exterior wall cladding and landscaping, the client's equipment was simultaneously being positioned, achieving concurrent construction acceleration. Through meticulous planning and excellent execution, CTCI REI lived up to the client's trust, completing the mission on time and to specification, which stands as the project's greatest highlight.

How sectional construction approach works.

Innovative Engineering Technology

Adopting Advanced Techniques to Create a Dust-Free Production Environment

The cleanroom constructed for this project serves as the primary location for the client's equipment manufacturing. It is divided into three classifications: Class 100 for clean welding, Class 1000 for equipment assembly, and Class 10000 for packaging. A higher classification number indicates a higher allowable concentration limit, thus representing a lower level of cleanliness. To ensure that each area meets the required cleanliness standards, and without using raised floors, the CTCI REI team implemented high-efficiency chillers and wall-mounted return air ducts. Air is filtered through high-density HEPA (High-Efficiency Particulate Air) filters in the ceiling to provide the client with a dust-free production environment. The design concept is outlined as follows: 1. Class 100: Air change rates are 175/60/40 times per hour, HEPA filter coverage rates are 50/15/10%, and Class 100 uses ULPA filters (Ultra Low Penetration Air Filter) with a filtration efficiency of 99.999%. 2. Class 1000/10000: Utilizes a HEPA filter with an efficiency of 99.99%. 3. Air Conditioning System Process: Make-up Air Unit (MAU) comprises a cooling coil, heater, humidifier, fan, primary/bag filter, and HEPA filter section → Air Chamber (located above the ceiling) → Mixes with the return air from the cleanroom, which has been cooled by the dry coil → Air is blown into the cleanroom through the FFU (Fan Filter Unit).

In the future, CTCI REI will continue to align with CTCI Group's goal of market expansion into high-tech industries by gaining advanced high-technology facility contracts. It aims to provide global renowned clients with the most reliable engineering services, backed by rich experience and track record.

Message from the Owner

We appreciate CTCI REI’s professionalism in overcoming challenges due to extremely unfavorable external terms, such as the rampant COVID-19 pandemic, rainy days for four months non-stop, and the narrow surroundings at construction site. Without CTCI REI’s unreserved commitment to respecting regulatory requirements and Merck’s own standards in terms of safety management, quality control, cost control, and scheduling, Merck could not have begun production on schedule. So, thank you. -Project director at Merck Group, Taiwan