Technology

技術分享

Optimizing Workflows with RPA Technology

— Da-Lun, Peng, R&D Engineer, Group Engineering Business (GEB), CTCI

CTCI has completed numerous challenging EPC projects around the world and understands that the efficient operation and automation of design, procurement, and construction processes are crucial to the success of project execution. Robotic Process Automation (RPA) is a technology based on software robots, suitable for handling repetitive tasks with clear rules. To improve project execution efficiency, CTCI has actively promoted and deepened the application of RPA technology in recent years, designing and developing RPA robots for various departments at different stages, including design, procurement, and construction. This article shares several examples of how RPA has optimized employees' daily tasks and reduced project execution risks.

Supporting Engineering Execution with RPA

RPA can automate various business processes, including data entry, data processing, and compliance checks. By reducing human errors, increasing operational efficiency, and freeing up employees’ creativity, it enhances both operational efficiency and quality.

Given that CTCI often undertakes large-scale projects with complex interfaces, effective coordination among multiple stakeholders and addressing potential risks are especially critical. Below are several examples of RPA that have been successfully implemented across multiple departments.

Application 1: RPA for PIPENET Automation

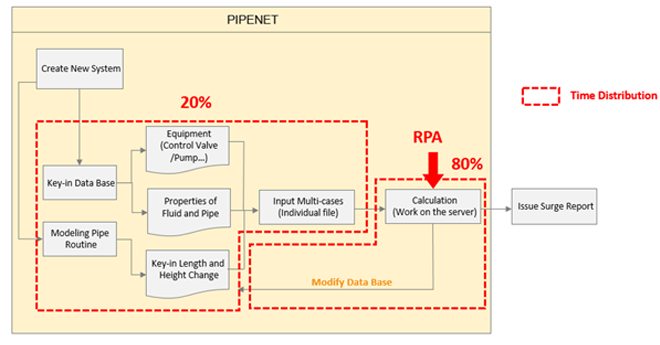

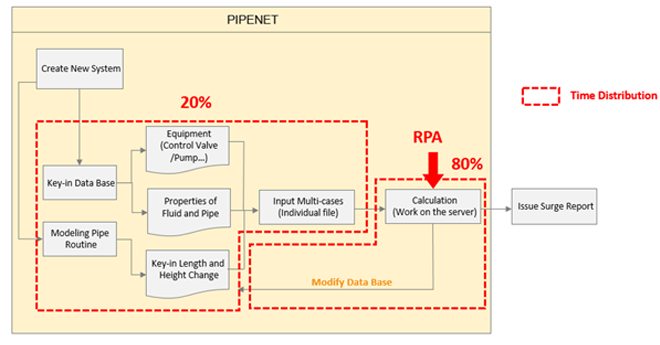

PIPENET is a professional pipe network design simulation system widely used in engineering fields such as petroleum, natural gas, chemicals, and water treatment. Its core functions include simulating various pipe design schemes and generating corresponding data reports to assist engineers in analyzing and optimizing pipe network systems. In the past, pipe engineers would manually input the designed parameter conditions into the PIPENET software, wait for the simulation to complete, and generate the results report.

However, this process has the following pain points:

Long simulation waiting time:

Due to the complexity of the calculation process and the large amount of data required, the PIPENET simulation process can be time-consuming, causing engineers to be unable to make effective use of their time while waiting for results.

User number limitation:

The PIPENET software has a limitation on the number of users who can access it at the same time, meaning that during peak usage periods, users will have limited access to the software, thus affecting work efficiency.

No user notification for results:

After the simulation is complete, PIPENET does not automatically notify users that the results have been generated, requiring them to continuously check the software status manually.

Manual input errors:

There is the possibility of incorrect data being entered manually, which can result in inaccurate simulation outcomes, thereby impacting engineering decisions.

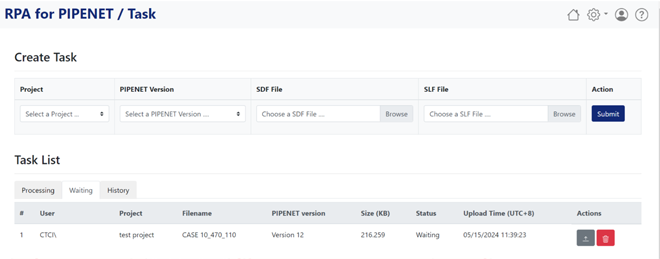

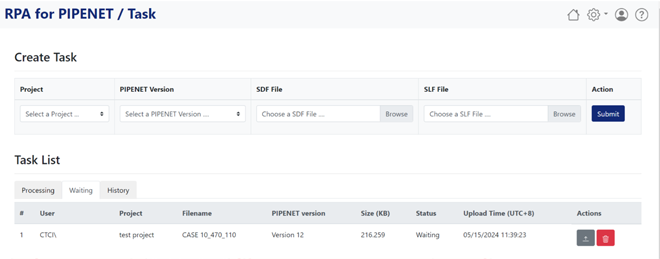

By using RPA and a web interface to systematize the process, the above pain points can be effectively resolved. Users only need to upload the files related to design parameters to the PIPENET Automation webpage developed by the CTCI team, and the RPA system will handle the process, achieving multiple benefits:

RPA automated simulation operation:

Once the file of the parameter is uploaded, the RPA system automatically starts the process, operating the PIPENET software to perform the simulation. The RPA mimics human operational steps, including parameter settings, simulation initiation, and result extraction, ensuring the accuracy and consistency of every step.

Real-time progress monitoring:

The PIPENET Automation website displays the real-time progress of the simulation, allowing users to monitor the interface at any time without needing to manually check frequently.

Result notification and report generation:

To ensure users can promptly receive the results for further analysis and design, the RPA system automatically sends an email notification once the simulation is complete.

RPA for PIPENET Automation enables pipeline engineers to allocate their time more effectively to design tasks, reducing 80% of the simulation waiting time in the original process. During peak design simulation periods, RPA can automatically balance and schedule tasks, further enhancing design efficiency. For example, in April 2024, RPA handled 31 pipeline design simulation tasks, running for a total of approximately 21.5 hours. This demonstrates that the system provides efficient and reliable support for pipeline design, allowing users to focus on higher-value tasks. As the number of projects increases, even greater benefits are expected.

Application 2: MRR Automation

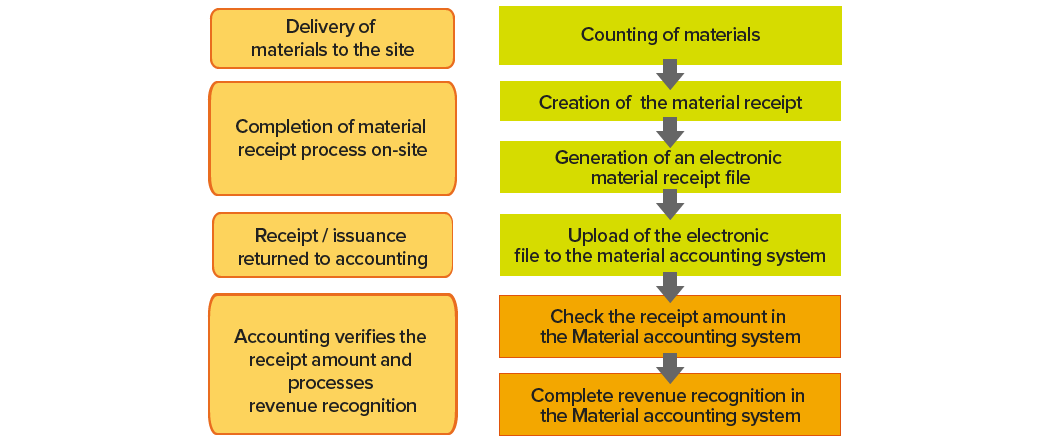

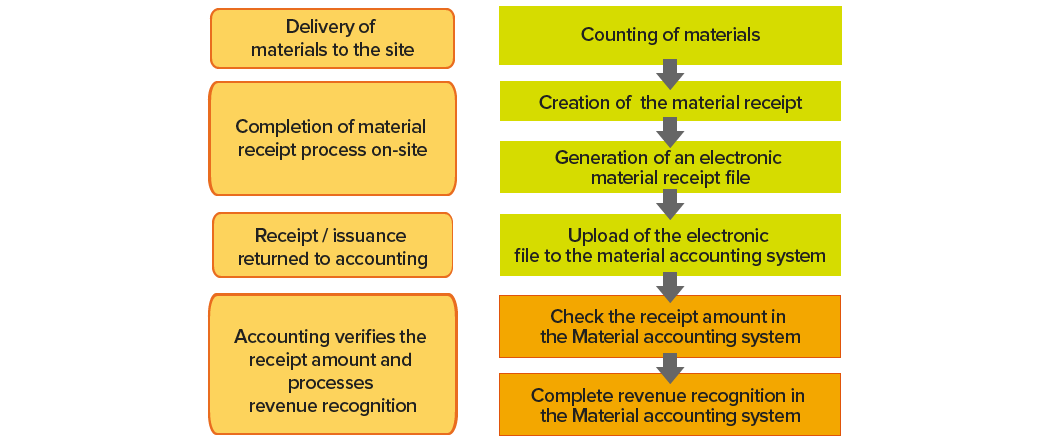

The Material Received Report (MRR), or material receipt, is a critical step in the process from warehouse inspection of materials on-site to financial recognition and accounting. The traditional MRR process is as follows: After the on-site warehouse department receives the materials, they create a goods receipt form in the material system. This electronic file is then uploaded to the material accounting system, where the finance department checks it. Once verified, the material system completes the recognition.

However, this process has the following pain points:

Multiple systems and complex processes:

The entire process involves material receipt, MRR creation, file upload, financial verification, and final recognition. It is complicated and requires the use of multiple systems. If the user is unfamiliar with these systems, errors are likely to occur.

Risk of human error:

Manual operations at each step can lead to data errors or missing documents, resulting in inaccurate material receipt and financial recognition.

Difficulty in tracking MRR:

The existing material system has loose controls over MRR usage, which can lead to incomplete information, making tracking difficult.

By integrating RPA technology with a web-based interface, the CTCI team has systematized the MRR process, effectively resolving the above pain points. Once the materials are received on-site and logged into the material system, the RPA system automatically completes the subsequent steps, with the finance department only needing to handle the final recognition. The key improvements brought by systematization include:

Fully automated operations:

Previously, users had to operate multiple systems manually. Now, RPA simulates these operations, ensuring a seamless connection between systems, eliminating manual complexity, and reducing errors.

Amount and personnel verification:

The system automatically checks the MRR amount as a safeguard. If any issues are found, the relevant personnel are immediately notified.

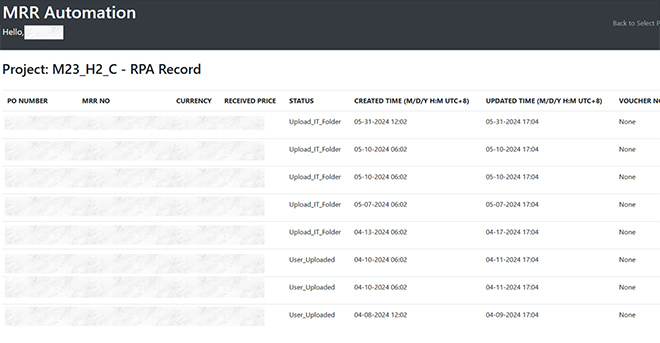

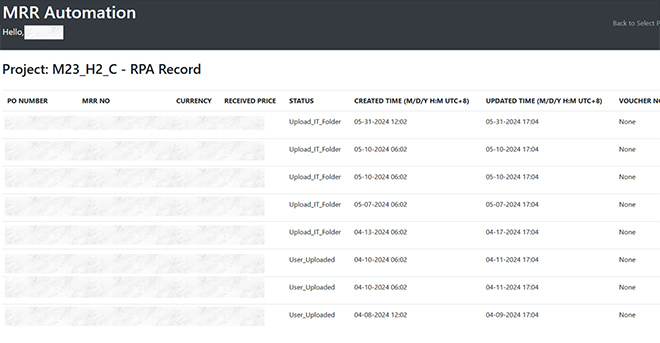

MRR process tracking:

Users can view the status of each MRR on the MRR Automation website, such as whether it is in the file download stage or already uploaded to the financial system, ensuring transparency throughout the process.

Result notification and report generation:

After the upload, the system automatically sends an email notification to the user.

In the MRR process, the introduction of RPA technology and a web-based interface has significantly improved the workflow. It has not only enhanced work efficiency and accuracy but also increased transparency and collaboration, providing a more efficient and reliable system for material receipt and financial recognition. All of CTCI's ongoing projects have now adopted MRR Automation. For example, in April 2024, more than 200 MRRs were automatically processed and uploaded, replacing the previous manual steps of printing, signing, scanning, and uploading. MRR Automation accelerates the material recognition process through full automation and actively notifies users of the results. This has greatly reduced processing time, while users can also check the progress of the workflow on the website, further increasing transparency and aiding relevant personnel in tracking the progress.

Future Prospects

From the examples mentioned above, it is evident that the application of RPA technology holds tremendous potential for enhancing operational efficiency and can bring greater value to enterprises. The following are some feasible directions for future development:

1.Automated Data Processing

RPA ensures data consistency and accuracy through automated data processing, thereby reducing the risk of human error. This not only strengthens trust within and outside the organization but is also critical for project management, as transparent and accurate data and reports are the foundation of project success.

2.Risk Management

RPA continuously monitors and analyzes various processes, helping companies identify and address potential risks. By integrating automated risk assessment, companies can respond more quickly, reducing the negative impact of risks on projects and overall operations. This is especially crucial for engineering projects involving multiple phases and collaborations, where the efficiency and accuracy of risk management often determine the project's success.

3.Streamlining Workflows

RPA can automate many complicated and time-consuming tasks, reducing the daily burden on employees, and allowing them to focus their energy and time on high-value and creative work. This not only helps improve job satisfaction but also fosters innovation and enhances overall team productivity.

4.Assisting in Optimized Decision-Making

In the past, much data was lost during processes, and decision-makers often had to make judgments based only on the results. With the introduction of the RPA system, complete data can now be retained, providing decision-makers with comprehensive reference points, thereby improving overall operational efficiency and increasing project success rates.