Discover Reliable

發現信賴

CTCI Builds the World’s First Industrial Wastewater Recycling Facility for Semiconductor Manufacturing—TSMC Southern Taiwan Science Park Water Reclamation Plant

— Dai-Ming, Li, Project Engineer, Group Engineering Business (GEB), CTCI

- Market category :Water resources

- Owner : Taiwan Semiconductor Manufacturing Company Limited

- Execution : CTCI Corporation

- Project period : June 2020 to September 2042

- Completion date : September 2022

- Project location : Southern Taiwan Science Park, Tainan City, Taiwan

- Scope of work :Investment, design, construction, and operation

- Capacity : 20,000 tons of reclaimed water for semiconductor manufacturing processes

The TSMC Southern Taiwan Science Park Water Reclamation Plant located in the Southern Taiwan Science Park, is a reclaimed water plant commissioned by TSMC to CTCI Corporation for investment, design, construction, and a 20 year operation under the Design, Build, Own and Operation (DBOO) model, in order to implement green manufacturing and manage water resource risks. This project is the world’s first successful reclaimed water plant that recycles industrial wastewater for reuse in semiconductor manufacturing processes, setting a significant milestone for global water resource recycling. It also effectively alleviates the water stress in the Greater Tainan area, making it one of CTCI's benchmark projects for "green engineering."

TSMC Southern Taiwan Science Park Water Reclamation Plant

Why Choose CTCI

An Experienced Advocate in the Water Resource Field

CTCI is Taiwan’s leading and one of the world’s top 100 EPC contractors, having completed numerous major projects both domestically and internationally. The company is frequently selected by renowned clients as their most reliable partner. In the field of water resources, CTCI boasts over 40 years of extensive experience and proven achievements. With its hands-on engineering expertise, it is able to turn feasibility studies into practical, full-scale implementations, setting the Company apart from its fellow competitors. Before the construction of this project, CTCI conducted effluent tests in an actual plant. Through continuous experimentation and iterative optimizations, they completed a successful pilot test, demonstrating the feasibility of the design and ensuring the successful execution of the project. Thus securing the contract with outstanding results.

Our Most Reliable Team

A Win-Win for Both Economy and Ecology with the DBOO Business Model

CTCI has been deeply involved in the field of water resources for nearly 40 years, consistently providing EPC turnkey engineering services for water, wastewater treatment, and wastewater recycling across various industries. This project marks the first time a private enterprise has adopted the DBOO business model, significantly reducing the company’s capital expenditures and operational risks, while having a profound impact on the industry. The successful execution of this project not only promotes environmental sustainability but also allows enterprises to simply pay for the reclaimed water usage without having to build or operate their own water treatment plants. This approach balances economic growth and environmental protection. In its early days, CTCI’s water resource projects primarily involved facilities for specific pollutant treatment or basic public infrastructure, including oil refinery and petrochemical wastewater treatment, industrial wastewater treatment, and municipal wastewater treatment for public use. For instance, more than 20 years ago, CTCI completed the world’s first petrochemical wastewater recycling project, the “CAPCO Petrochemical Plant Wastewater Treatment and Recycling Project,” pioneering the use of dual-membrane UF+RO technology to produce reclaimed water, which was featured in international journals (click the Link to read). Besides, CTCI introduced advanced high-efficiency oxidation technology in the highly challenging turnkey wastewater treatment project at the Oriental Petrochemical’s PTA Plant in Guanyin. This project, which involved highly challenging technical standards, used customized solutions to help the client treat high-concentration wastewater in an environmentally friendly manner. Recently, in response to the global opportunities in water resource recycling, CTCI has focused on innovative developing in diverse water resources projects. Collaborating with both government and private sectors, CTCI has co-developed processes for reclaiming municipal wastewater that meets tap water standards and recycling industrial wastewater. Examples include the Fengshan and Linhai Water Resource Centers in Kaohsiung, as well as the wastewater recycling plants at CPC Lin-yuan and Dalin refineries. For this project, CTCI applied its self-developed "iEPC" and "iManagement" platforms with outstanding results, achieving stable water supply and quality while overcoming challenges posed by natural water conditions. This project stands as a model for water resource recycling and the development of alternative water sources.

Project Highlights

Pioneering Diverse Water Resource Solutions to Meet Demand for Semiconductor Processes

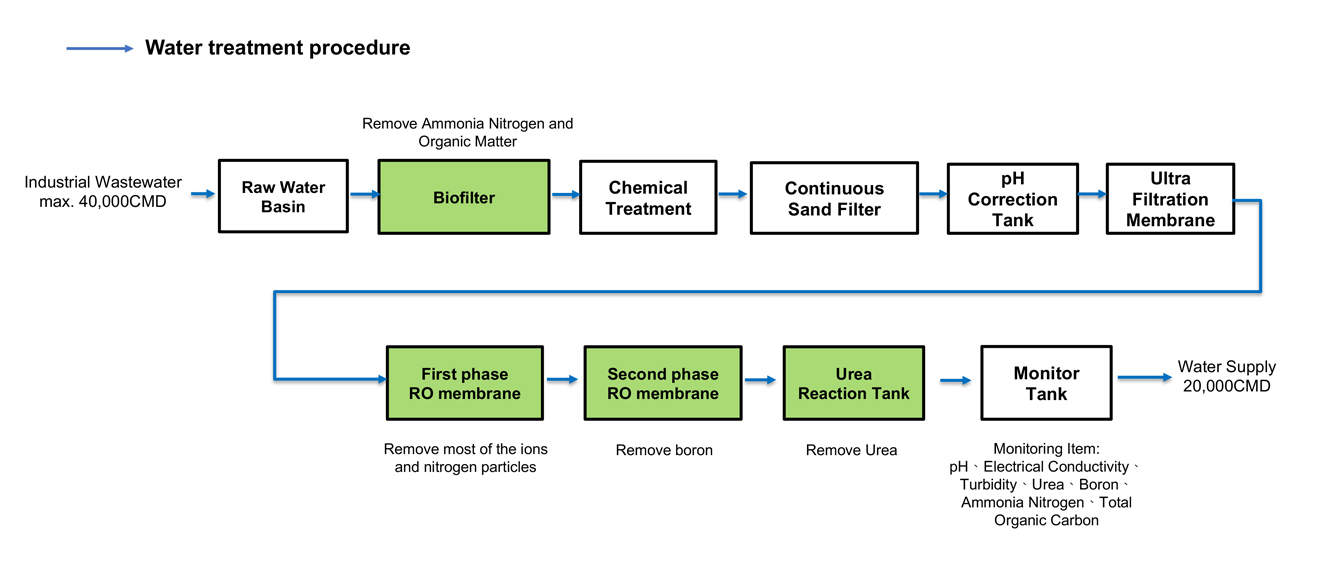

This project is the world’s first water reclamation plant to reuse industrial wastewater in semiconductor manufacturing, marking a global milestone in green technological innovation. The raw water treated by this plant is complex industrial wastewater, containing many small molecules that are difficult to treat, making it more challenging than treating municipal wastewater. Since the reclaimed water is to be reused in semiconductor manufacturing, which requires extremely high purity—nearly to the level of ultrapure water—there are stringent quality requirements to ensure the stability and yield of precision semiconductor processes. The treatment is highly challenging, as shown in the diagram below.

Reclaimed Water Treatment at Southern Taiwan Science Park Water Reclamation Plant

The plant currently produces 20,000 tons of water daily. In line with the diverse water resource policy and facilitated by the government, domestic reclaimed water from Tainan region has also been introduced as a supplementary water source. Under the strict water quality monitoring by the CTCI team, the total supply is expected to reach 67,000 tons per day throughout the project's entire duration. By 2026, the plant will expand its capacity to 30,000 tons per day, and with additional regional water sources introduced, the total water supply will reach 110,000 tons per day, further enhancing water resource autonomy. The plant's exceptional water quality and effectiveness not only successfully develop new water sources but also serve as a model for establishing reclaimed water plants in industrial and science parks nationwide. Moreover, it has alleviated concerns within the technology sector regarding the use of reclaimed water, making it highly significant.

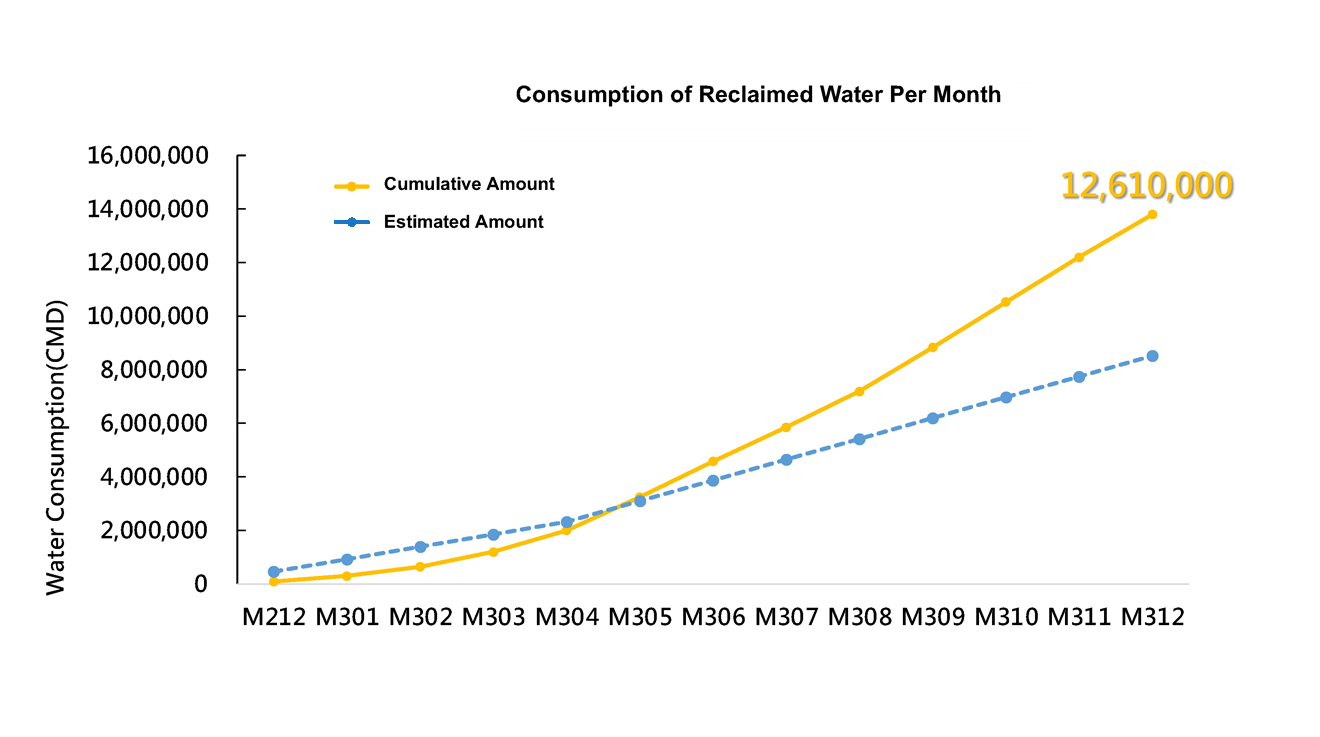

Saving 30% of TSMC’s Water Usage at Southern Taiwan Science Park

The goal of this plant is to reclaim and purify industrial wastewater for use in semiconductor manufacturing, achieving benefits such as reducing industrial wastewater discharge, stabilizing the industrial water supply chain, and increasing water resource availability. Since the plant’s commissioning in September 2022, reclaimed water was officially introduced into the semiconductor wafer manufacturing process in January 2023. Throughout 2023, the plant provided TSMC’s facility at Southern Taiwan Science Park with a total of 12.61 million tons of reclaimed water, equivalent to the capacity of Baihe Reservoir, or about 630,000 truckloads of water delivery (20 tons per trip). The plant plays a crucial role during the dry season, significantly reducing the energy consumption and environmental impact of water transportation, becoming a powerful tool for TSMC in combating extreme climate conditions, laying a solid foundation for industrial growth and economic development.

The cumulative reclaimed water usage of TSMC’s facility at Southern Taiwan Science Park in 2023 (M301 as of January 2023)

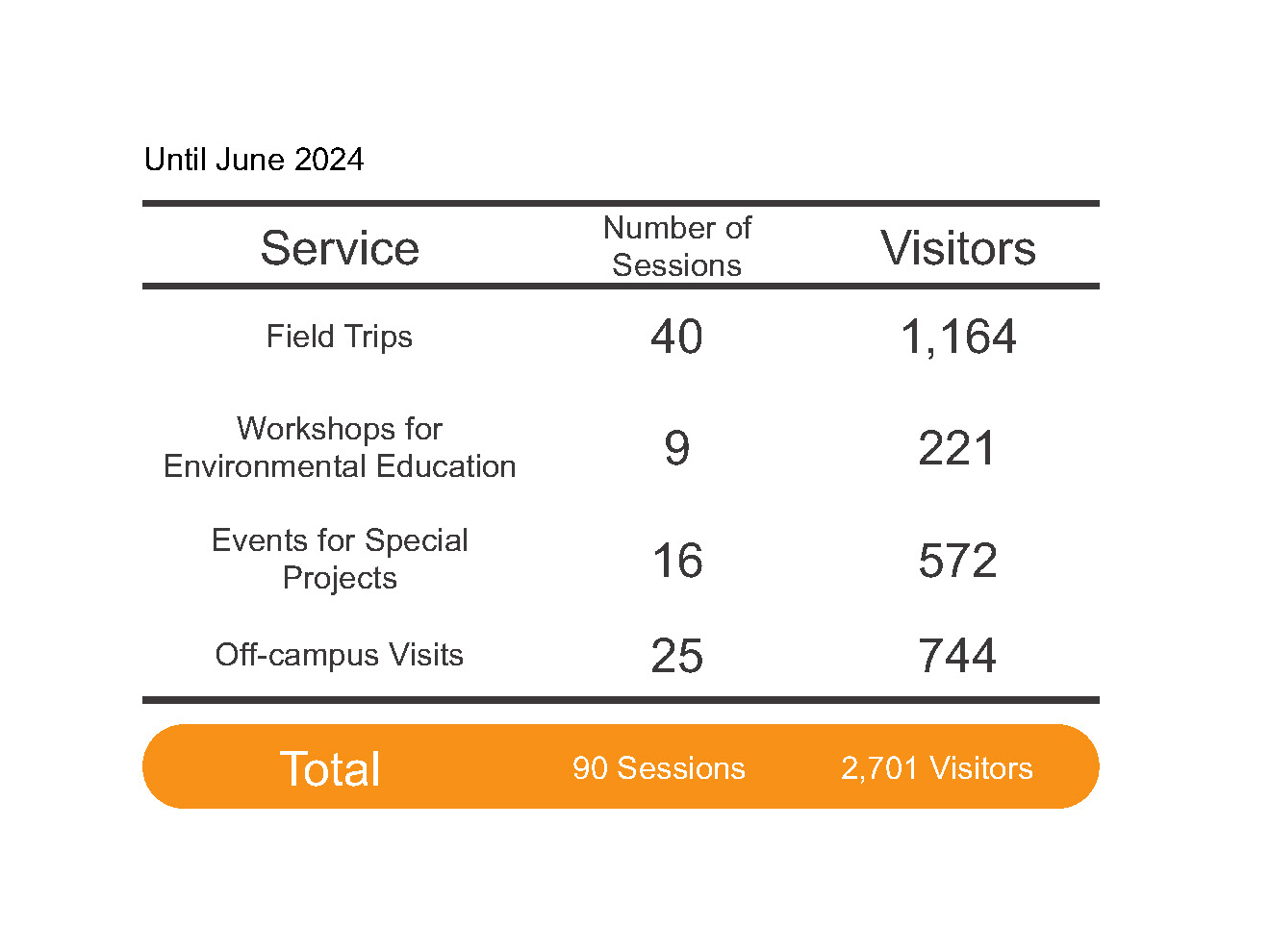

Implementing ESG Across the Board: A Top Choice for Environmental Education in Southern Taiwan

CTCI regards itself as "A Guardian of Sustainable Earth " and has long been dedicated to fulfilling its corporate social responsibility. Since the commissioning of this plant, CTCI has established an environmental education facility to promote sustainability, environmental education, and the concept of green engineering, while deepening the connection between technology industries and the local community. In December 2023, the plant received certification from the Ministry of Environment as an official environmental education facility, aiming to promote the importance of next-generation industrial technological development and the symbiotic relationship with Earth’s sustainability. As of now, the environmental education center at the plant has hosted over 90 events and welcomed more than 2,700 visitors, including domestic and international government agencies, schools, academic and industry associations, and international organizations, receiving high praise from industry, government, academia, and research sectors.

Statistics on events hosted and visitor numbers at the environmental education center

Innovative Engineering Technology

Introducing Innovative Water Treatment Technology: Pioneering AIoT Intelligent Control for Precise Dosing System

This plant utilizes advanced innovative technologies developed by the Industrial Technology Research Institute, such as the BioNET and the "Fluidized Bed Crystallization technology (FBC)." At the time, these technologies had not yet been widely applied in full-scale operations. However, this advanced biological treatment, with its low-pollution-load, not only produces water of higher quality than traditional biological treatment methods but also significantly reduces energy consumption and minimizes sludge production. These innovative approaches address the challenges posed by raw water conditions and production water requirements, while utilizing environmentally friendly green technology to achieve energy savings and carbon reduction, achieving multiple environmental protection benefits such as reducing secondary pollution. This aligns with CTCI's commitment through its professional expertise in "green engineering."

The chemical treatment (FBC, left) and biological treatment (BioNET, right) applied at the Southern Taiwan Science Park Water Reclamation Plant

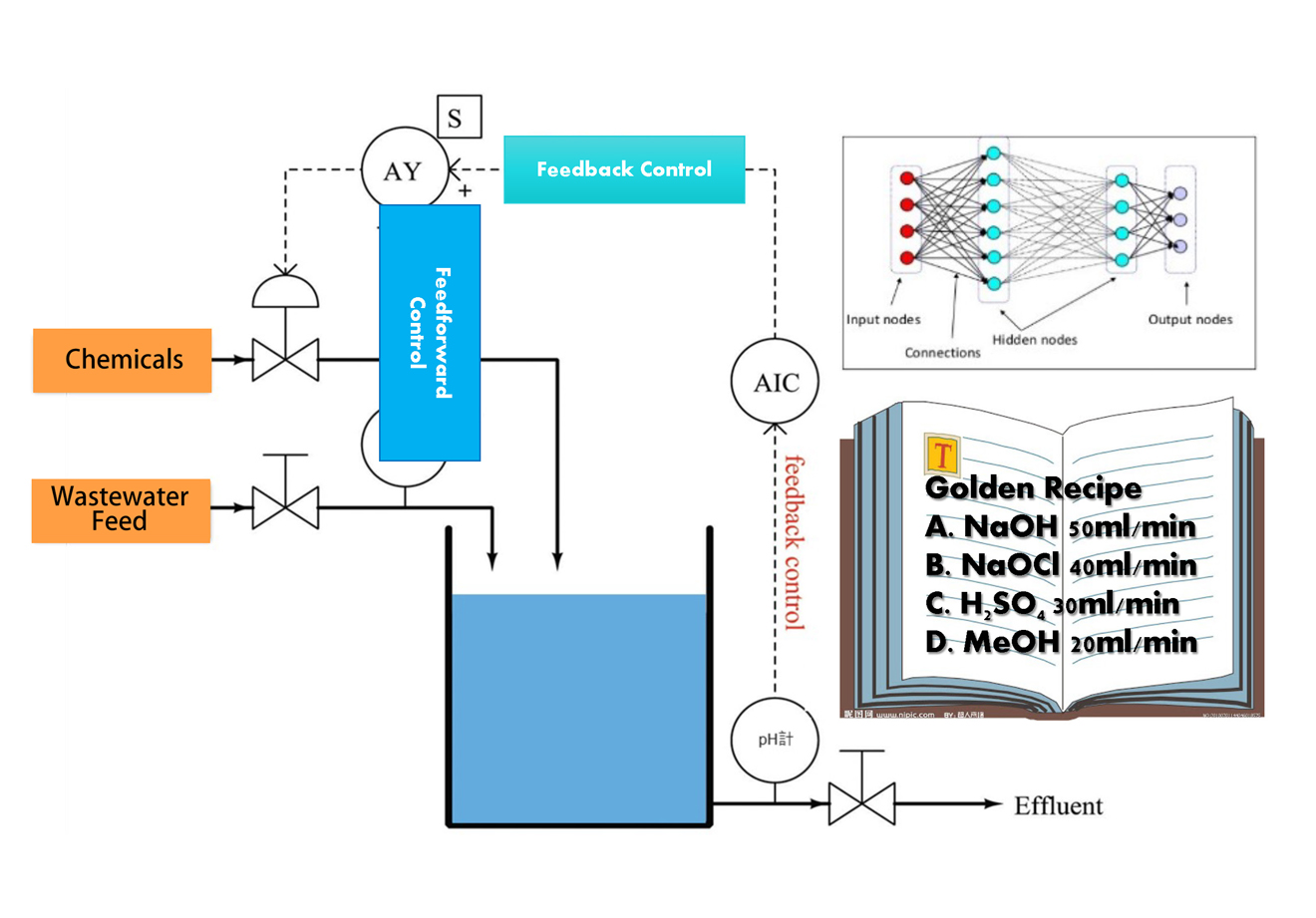

Concept of the AI model developed for the Southern Taiwan Science Park Water Reclamation Plant

Unlike municipal wastewater, which has simpler and more stable quality, the plant treats a water source with complex quality that varies depending on the operations and processes of factories within the science park. Moreover, the treated water still needs to meet the strict standard required for the production of semi-conductor components, which put a test to the plant’s buffering capacity and responsiveness. With nearly two years of operational experience, CTCI has leveraged smart technology to develop a logic flow. By utilizing data analysis models along with scenario analysis and experience-based insights, the team is able to identify optimal practices and has successfully developed an AI model based on the most suitable standardized operational procedures. This model processes digitalized information, setting inlet water quality, flow rates, and recirculation flow from certain treatment units as feedforward control, while the outlet water quality serves as part of the feedback control system, forming a recurrent neural network (RNN). Currently, this AI model is still being refined. Once deployed onsite, it will replace manual, experience-based operations with automated responses and adjustments, leading to a 10-15% reduction in chemical consumption, thus preventing wastage. Additionally, this will ease the burden on operators, shorten response times, and even proactively detect potential anomalies, enabling early environmental assessments and reducing the likelihood of operational issues.

Message from the Management Team

This water reclamation plant has pioneered several groundbreaking initiatives that continue to shape the future of the water market. Its outstanding contribution to water resources management and commitment to environmental education have been recognized with the inaugural "Water Sustainability Award" from the Ministry of Environment. The plant's expansion is currently under review to increase its existing capacity. Drawing on its extensive experience in the water resource sector, CTCI will continue to explore the applications of reclaimed water, accelerating the development of emerging water resource industries and technologies. We aim to encourage various industries to actively adopt reclaimed water, moving toward a sustainable future. -Chih-Chun, Liu, Senior Manager, Water Resources Engineering Department, Group Engineering Business (GEB), CTCI