Sustainable Future

永續未來

Deepening our understanding of the circular economy to address the challenges posed by climate change

— Chun-Wei Chang, Manager at Quality Assurance Department, ECOVE, Group Resource Recycling Business — Jui-Yun Hsu, Engineer at Quality Assurance Department, ECOVE, Group Resource Recycling Business

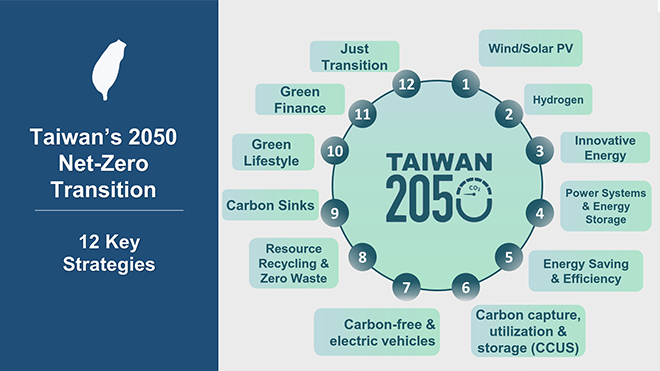

Climate change is a challenge that every member of the global community must actively confront. According to a report from the Ellen MacArthur Foundation, 55% of global carbon emissions are attributed to energy, while 45% are linked to product manufacturing. Therefore, implementing a circular economy to reduce carbon emissions in the manufacturing process is a crucial approach to achieving net-zero goal. The National Development Council of Taiwan has identified zero waste as one of the twelve key net-zero strategies.

The National Development Council has announced the 12 key strategies for achieving net-zero emissions by 2050.

CTCI Group prides itself on being the ”Guardian of Sustainable Earth”' and has a longstanding commitment to sustainable development in its core business. ECOVE, a subsidiary of the group, shares the same spirit and has been dedicated to promoting resource circulation for over 30 years, focusing on the circular economy in all business areas. This article will discuss how ECOVE plans its carbon reduction strategy and actively capitalizes on the business opportunities that arise from the impacts of climate change.

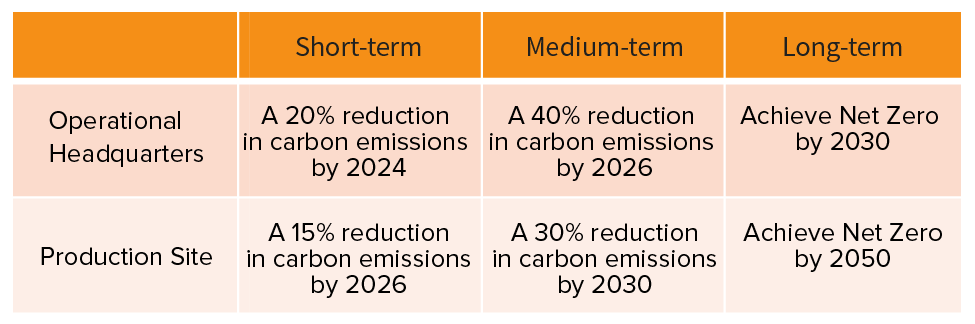

Developing Short-term and Long-term Strategies to Reduce Carbon Emissions and Achieve Net-Zero Goals

The Sustainable Development Committee of ECOVE has been established for more than 10 years acting as a compilation unit, dealing with various sustainable and net-zero matters . Since 2017, it has adopted the BS8001 Circular Economy Standard, gradually applying it from the resource management sector to the entire business sector. In 2020, ECOVE’s entire line of business received the world's first certification statement for the Circular Economy Standard.. In order to strengthen the organization's resilience in the face of climate change, the Task Force on Climate-related Financial Disclosures(TCFD) management framework was implemented in 2020. An assessment of the risks and opportunities associated with climate change was conducted on a yearly basis, leading to the implementation of further operational and management strategies.. In response to the demand for achieving net-zero carbon emissions, ECOVE has developed climate performance indicators for reducing carbon emissions (Scope 1 and Scope 2) at production sites under long-term operational control. These indicators are based on the TCFD results . With the Science Based Targets initiative (SBTi) approving CTCI’s the net-zero reduction, ECOVE follows the example of its parent company, establishing short, medium, and long-term carbon reduction targets of its subsidiaries with significant operational control. These targets, shown in the table below, are based on the year 2022 as the baseline and aim to align with the goal of limiting the increase in global temperature to within 1.5°C, as outlined in the Paris Agreement. ECOVE aims to achieve net-zero emissions at its headquarters by 2030, along with a 30% reduction in carbon emissions at production sites. The Company projects a 33% decrease in overall carbon emissions compared to the baseline year. The ultimate objective is for all production sites to reach net-zero emissions by 2050. In order to achieve this goal, ECOVE has developed the following short-term and long-term strategies for reducing carbon emissions: Short-term Carbon Reduction Strategy (2023-2030): The strategy aims to reduce carbon emissions by adopting low-carbon energy, green technology, intelligent systems, and CCUS (Carbon Capture, Utilization, and Storage) technology development. Additionally, there will be an increased focus on the use of renewable energy. Long-term Carbon Reduction Strategy (2030-2050): The goal is to reduce carbon emissions by adopting energy storage technology, utilizing decarbonized energy sources, and implementing CCUS technology. If there are any remaining carbon emissions that cannot be reduced due to current technological limitations (aiming for less than 10% of total emissions), carbon credits will be purchased as offsets to achieve net-zero emissions.

ECOVE Operations Headquarters and Production Sites' Carbon Reduction Goals

Advanced Deployment of Technological Integration: Addressing Climate Impacts Effectively

After analyzing the financial risks and opportunities associated with climate change, ECOVE is confronted with substantial physical risks, specifically the impact of drought and high temperatures resulting from extreme weather on the Energy Resource Center (waste incineration power generation). In light of this challenge, given that the air pollution control system at the Energy Resource Center is a water-intensive process, ECOVE has not only developed a comprehensive contingency plan for drought and water shortage but has also made proactive investments in advanced dry acid removal technology. Using the operational Gangshan Incineration Plant as an example, it is estimated that the adoption of advanced processes can reduce water consumption by 0.3 tons per ton of waste treated. In order to address the issue of decreased power generation efficiency caused by high temperatures, ECOVE has implemented technological integration. This integration involves transforming the air-cooled condenser into a flat tube design and adopting a low-resistance FRP fan design, all without impacting the building structure. As a result, heat exchange capability is greatly enhanced and fan energy consumption is reduced. Taking the Tainan Chengxi Incinerator Extension Project as an example, the steam power generation efficiency per ton has increased by 14.5% after improvement, and the energy consumption of the air-cooled condenser has decreased by 16.7%.

The air-cooled condenser utilizes a flat tube bundle

In response to the zero-waste policy and trend, we are actively pursuing sustainable green business opportunities.

In response to the government's policy on waste management with added value

Under the national sustainable development strategy for value-added waste treatment, the future direction for domestic waste management is to promote the utilization of resources and the recovery of energy from waste. Through the business model of the circular economy, ECOVE combines the operation and management of energy resource centers, intelligent data management, equipment upgrades, and other successful experiences and professional capabilities. ECOVE has obtained over 40 system technology patents for incineration power generation, effectively prolonging the equipment's lifespan and enhancing energy utilization efficiency.

Currently, the first new generation treatment plant in Taiwan, known as the Taoyuan Biomass Energy Center, is operated by ECOVE. The incineration power generation efficiency of this project reaches 27%, which is more than 30% higher than that of traditional energy resource centers. Simultaneously, the ash residue generated during the incineration process is converted into controlled low-strength backfill material (CLSM) through the ash residue treatment facility within the center, achieving the goal of waste materialization. To tackle the problem of high moisture content in kitchen waste that cannot be incinerated, the Company implemented advanced international anaerobic digestion technology to produce biogas for power generation. The resulting digestate and digestate liquid also offer significant potential for resource utilization. The waste treatment operation model of the Taoyuan Biomass Energy Center is in perfect alignment with the government's sustainable goal of value-added waste management. Based on the aforementioned experience, ECOVE, in collaboration with its parent company, CTCI, has secured the development rights for the ”Chiayi City Green Energy Recycling Center BOT Project” by the end of 2023, leveragingCTCI’s strong EPC contracting capabilities. Additionally, this project boasts an impressive incineration power generation efficiency of 27%. Furthermore, by capitalizing on ECOVE's expertise in solar photovoltaics, the administrative building will meet the standards of net-zero construction.

Taoyuan Biomass Energy Center

ECOVE has developed a technology for recycling and reusing waste Isopropanol (IPA) with a concentration of over 99.9% in the high-tech industry. They have also obtained multiple patents for this innovation. We will continue to prioritize the development of high-value electronic-grade products in the future and implement advanced recycling technology in our factories. In addition, ECOVE is actively collaborating with academic institutions to develop the Edge Bead Removber (EBR) recycling technology in order to expand its service scope. It will also meet the high-tech industry's demand for a circular economy by integrating various recycling projects and assisting in the establishment of a zero-waste center, while providing ongoing operational maintenance services. Development of Opportunities in Water Reuse and Seawater Desalination In response to the water shortage problem caused by climate change, the National Climate Change Adaptation Action Plan (2023-2026) aims to increase the use of technology-based water production methods, such as recycled water and desalinated freshwater, in areas with water scarcity, such as the Science Park and the central and southern regions. This will improve water supply resilience by diversifying water sources. In addition to operating and managing existing water treatment facilities and a recycled water plant, ECOVE has also expanded its operations to include the recycling of wastewater in the high-tech electronics industry. For example, the operation and management of the 'Southern Taiwan Science Park Water Reclamation Plant ', constructed by the parent company, CTCI Corp.It is the world's first facility to successfully regenerate industrial wastewater and reuse it in the semiconductor process.ECOVE has received commendation from customers for its reliable water supply and clean water quality, both of which are crucial factors. In the future, ECOVE will actively pursue investment and operational opportunities for the construction of a wastewater treatment plant and a seawater desalination plant. Rapid Growth in Renewable Energy and Related Fields The United Nations Climate Summit COP28 has resolved to triple the installation of renewable energy sources by 2030, which will result in a significant rise in the global demand for green electricity. ECOVE has invested in and developed over 100 solar power plants in Taiwan and overseas with a solid record, and is one of the few companies in Taiwan that can provide one-stop services from investment, development, construction, operation to green power trading. In addition to continuously investing in and developing domestic solar photovoltaic projects, ECOVE has expanded its cooperation internationally with the acquisition of 100% ownership of the Lumberton solar power plant in New Jersey, USA; a MOU for renewable energy procurement cooperation was also signed with the New Jersey Institute of Technology last year. Moving forward, the Company will continue to utilize the local advantages of CTCI Americas, Inc. to actively pursue the expansion of Phase II of the Lumberton plant and explore further investment opportunities. The goal is to become a major investor in large-scale photovoltaic and energy storage in the United States.

ECOVE Chairman Jun Jer Liao (center), General Manager Eric Tiao (right), and Dr. Teik Lim, President of New Jersey Institute of Technology (left), are pictured signing a memorandum of cooperation .

ECOVE actively responds to the government's ancillary service policy by introducing privately provided power grid servicesand has successfully expanded into the energy storage field. For example, the 5MW energy storage system in the Nangang Industrial Park has been connected to the grid and participated in Taipower's automatic frequency regulation assistance services in the fourth quarter of 2023. In terms of green energy trading, ECOVE has signed green energy supply contracts with the government and corporations, steadily increasing trading volume. By supplying electricity to the government or corporations to meet their green energy needs and help them achieve their net-zero planning goals. ECOVE will also utilize its strengths in the solar photovoltaic and waste-to-energy sectors to create green energy certificates. These certificates will not only fulfill the net-zero requirements within the group but also offer a range of net-zero services for businesses.

Conclusion

ECOVE is an advocate of the circular economy. Its four main business pillars, which include 'waste management, recovery, renewable energy, and mechanical and electrical maintenance and improvement,' are all closely aligned with the principles of net zero sustainability. Moving forward, ECOVE will continue to promote and capitalize on the advantages of resource cycling businesses, expand its influence, and offer diverse and sustainable economic solutions to clients and the government. Together, we will tackle climate change and achieve the objectives of sustainable development and net zero carbon emissions.