Technology

技術分享

Discussion on Same-Floor Plumbing for Apartment Buildings

— Chi-Cheng Chen, General Manager, Mechanical Department, CTCI SEC, Group Intelligent Solutions Business

Regarding plumbing planning for residential buildings in Taiwan, the most common method is to install it through the floor. This method of placing piping in the ceiling of the occupants on the lower floor violates the private area of the lower floor, leading to disputes. As a result, the “same-floor plumbing” approach was born. In this article, we will share CTCI SEC's experience and views of using this method.

Through-floor vs. same-floor plumbing

The through-floor plumbing design is the most common form of plumbing planning in Taiwan’s residential buildings. The advantages include a limited scope of damage, easy recovery, short construction time, and relatively low cost. The main disadvantage is that when repairs are required, while the right of the upper floor to undertake work is protected by the Condominium Administration Act Building Administration Division.” However, construction work causes more significant interference to the lower floor, and is thus likely to cause disputes. This spawned the addition of Article 29-1, “Same-Floor Plumbing,” to the Building Technical Rules Building Equipment Section, which came into effect this January (2023). Although same-floor plumbing is encouraged, but not mandatory, the planning and design should still be reviewed first, as well as the construction details and interface procedures, etc., to prepare to meet the needs of future mandatory implementation. The pipes of a same-floor draining system, as the name would imply, are installed inside the same floor on which they will be used. The advantage is that when addressing plumbing problems, repairs of leaks can avoid hitting the main structure. The disadvantages are long duration of work, a complicated process, and a high cost that is not affordable to the general public.

Common same-floor plumbing construction methods

In practice, the most common same-floor plumbing construction methods are as follows:

1.In-Floor Plumbing

This construction method is currently more commonly found in luxury buildings in Taiwan. The practice is to sink the structural floor 30-60 cm to serve as a layer of horizontal sewage drainage pipe-laying space. Wastewater drainage with total storage water bends as an indirect collection and maintenance relay point. Before the sewage is connected to the vertical pipe between pipelines, a ventilation pipe should be provided to maintain the water seal of the water reservoir. The advantage is that property areas can be differentiated and reduce occupant interference. The first case of using this in the bathroom space was The Palace Mansion, which adopted an in-floor design. The CTCI team also took on a project at a luxury home in Taichung. In general, luxury homes are designed to place a premium on privacy, and bathrooms are not close to public spaces. To reduce noise interference during construction, work even made use of insulated soundproof structural slabs with a thickness of 25cm. Bathing equipment configuration in the same area allows the owner to adjust the sanitary equipment configuration independently.

In-floor plumbing schematic.

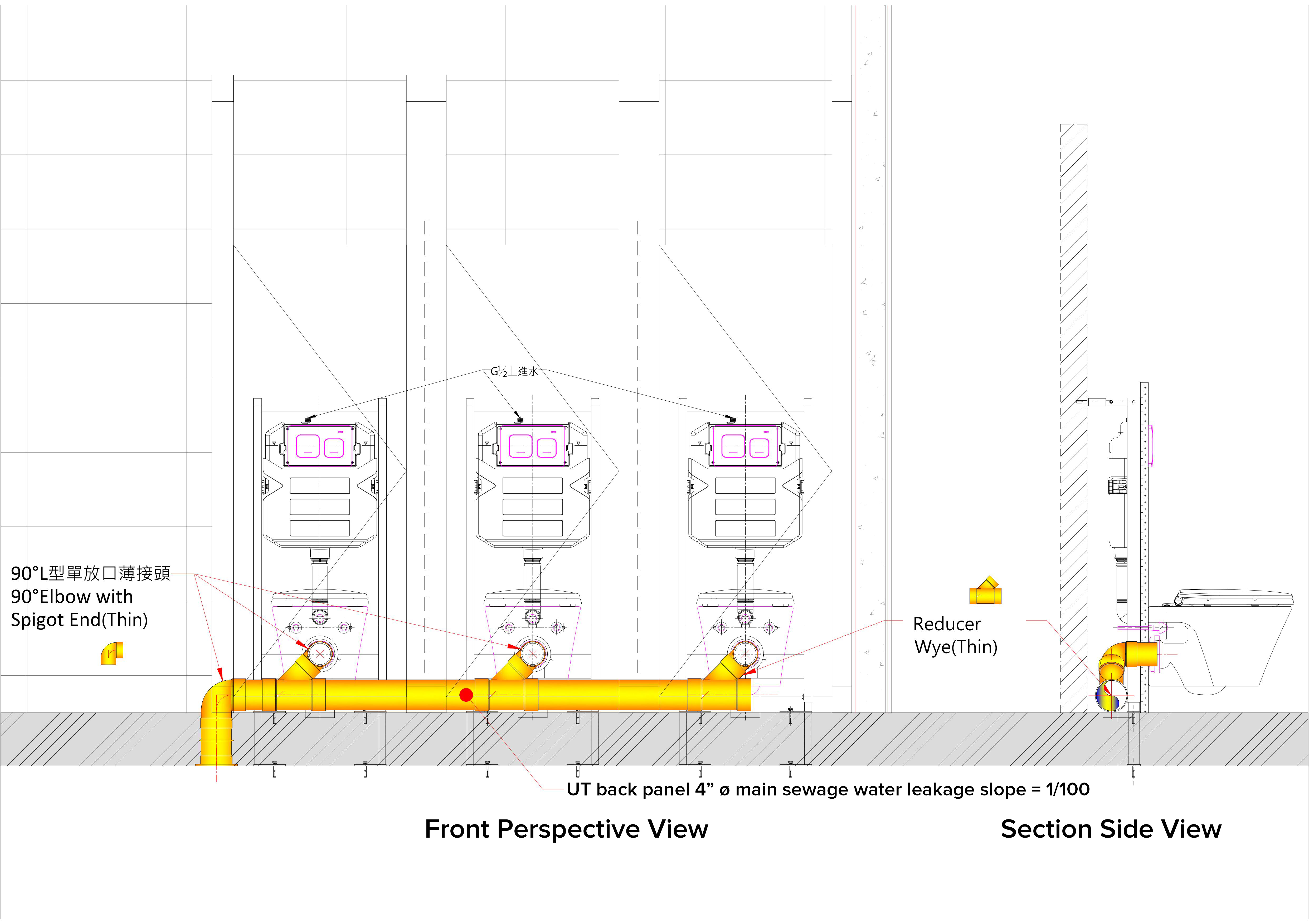

2.In-Wall Plumbing

This construction method is most commonly used for public toilets in commercial or public buildings, such as offices, hotels, and gyms. The CTCI Second Headquarters Building, built by CTCI, uses this approach. This practice involves adding more than 15cm of false wall in front of the structural wall, employing a wall-mounted appliance with a metal skeleton as the main structure. This is adjacent to the low UT (Unit-Toilet) wall between the pipes for water supply, sewage drainage, and ventilation piping. However, this method still requires the establishment of floor drainage, which must inevitably be carried out by downward or embedded buried plumbing. If it is a general residential house, it should be planned within the range of the drain, and the floor should be partially thickened to facilitate pipe burial. This limits the low point of the floor drainage slope, which should be as close as possible to the bathroom, which can achieve better drainage effect and ease of access.

In-wall plumbing schematic.

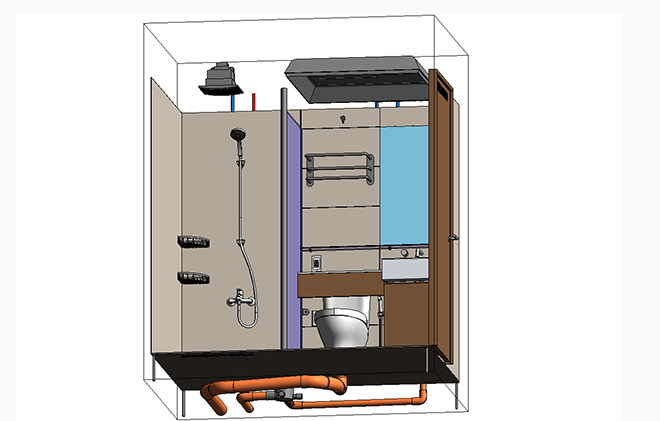

3.Elevated Piping

The principle of this approach is to use a raised bathroom floor, which will however reduce the indoor net height. This structure raises the floor of the equipment installation by about 20cm to serve as a piping space. It is commonly used in Taiwan for old house renovation, sanitary equipment resetting, and other scenarios in Taiwan. In practice, it is more common to connect the existing sewage pipe to the structural floor plumbing. However, due to the limited slope of water drainage and the inability to install ventilation pipes (which old houses lack), drainage is inevitably less smooth and there may also be other problems. In addition to the renovation situation above, for the newly built raised bathrooms, the overall bathroom floor is thickened to accommodate a small in-floor structure (which can also serve the function of a sound insulation panel to prevent noise transmission). The whole sanitary equipment is assembled on the structural floor with only a waterproof layer coating. Considering the limitations of piping space and the inability to cross pipes, sewage drainage must be pre-planned with separate routings. Additionally, circular ventilation piping does not connect to the area. To facilitate drainage and water seal maintenance, the sewage pipe should be connected to the pipeline, vertically down into the sewage riser pipe, and upward to the ventilating pipe riser, with a minimum space between ducts to accommodate pipeline connections.

Elevated piping schematic.

Perspective and experience with the same-floor plumbing method

After research and evaluation of trends, as well as experience with projects such as luxury homes in Taichung and CTCI Group’s second headquarters building, CTCI SEC has come to the following conclusions:

1.The Cost Perspective

Waterproofing work for bathrooms, kitchens, and other areas should be fully implemented up to 180cm to ensure a complete waterproofing effect. However, this also creates a cost burden. Although this method only needs to involve same-floor construction, with no need to enter the lower floor for maintenance, the maintenance procedures are more complicated. However, it can reduce interference with neighbors and thus avoid disputes. It also involves more time and expense than through-floor plumbing.

2.Water Leakage Sources should be Carefully Managed

Water use areas should make use of water stop piers and waterproofing methods to limit the area of water damage. Waterproofing work is required for bathrooms, kitchens, working balconies, etc. Waterproofing work for bathrooms and kitchens, where large amounts of water are used, should be fully implemented to 180cm high. In addition, for the waterproofing of in-floor spaces, be sure to test the water, conduct leak testing, and check floor leakage slopes and install small size floor drains. This ensures that minor leaks do not directly affect the lower floor during repairs. In addition, the sewage pipe connection method and the layout between pipes must be pre-planned to ensure feasibility. The access doors between pipes should open toward public space so that subsequent inspections are not restricted.

3.No Water Supply Pipes should be Buried in Structural Floors

In construction in the 1990-2000s, water pipes were generally buried in structural floors. However, when the water supply pipes are damaged, leakage often circulates along the water and electrical pipes embedded in the structure or through small cracks in the structure. It is thus difficult to accurately determine the pipe damage point, resulting in high repair difficulty. It is often necessary to stop the water and cut into the lower floor, disturbing the occupants. Given this, the current stage of plumbing construction planning should consider the ability to replace pipes with the minimum of damage and fastest recovery. Therefore, hot and cold water supply pipes should not be buried in structural floors, and relevant designs should be optimized, with pipe replacement able to be quickly done by cutting pipe grooves.

Conclusion

Looking forward, CTCI Group will continue to focus on relevant trends, invest in research and application technologies such as same-floor plumbing, and accumulate related achievements. Once the future policy is on the road, we can respond quickly to our needs and strive to provide our customers with the most reliable quality engineering services.