Discover Reliable

發現信賴

CTCI Builds Taiwan’s First Ever High-temperature Waste Treatment Facility in Cement Kiln

— Sheng-Wang Chang, Project Manager at CTCI Resources Engineering Inc., CTCI Group Intelligent Solutions Business

- Market category:Construction

- Owner:Taiwan Cement Corporation

- Contractor:CTCI Resources Engineering Inc.

- Completion date:April 2024

- Location:Heping Village, Xiulin Township, Hualien County

- Project scope:Construction and E&M procurement and installations

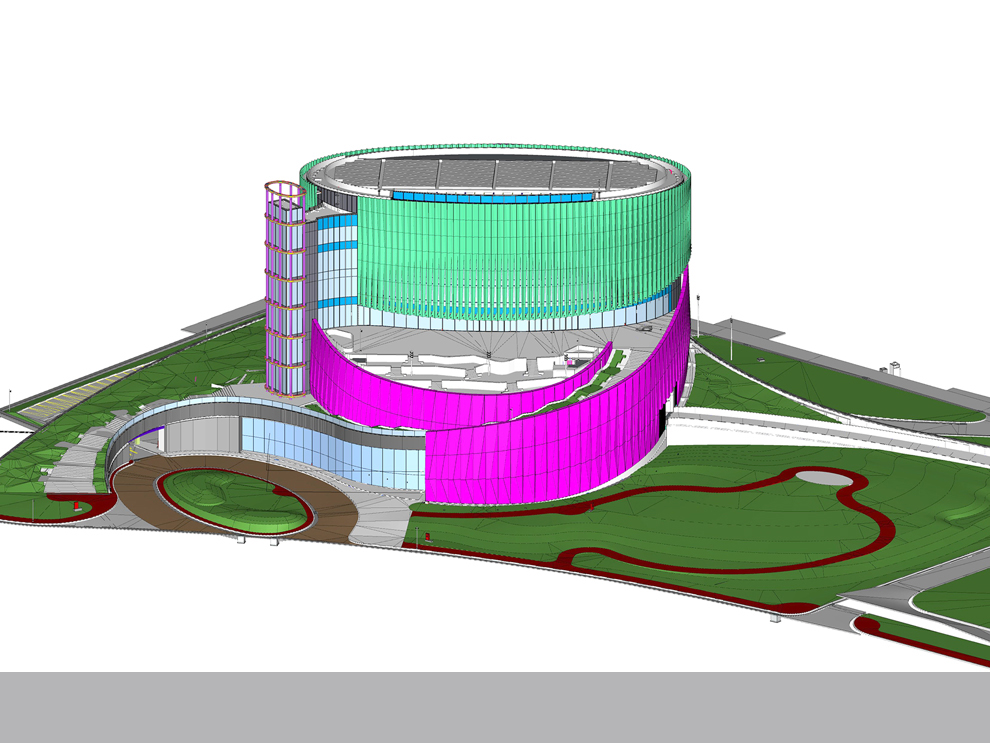

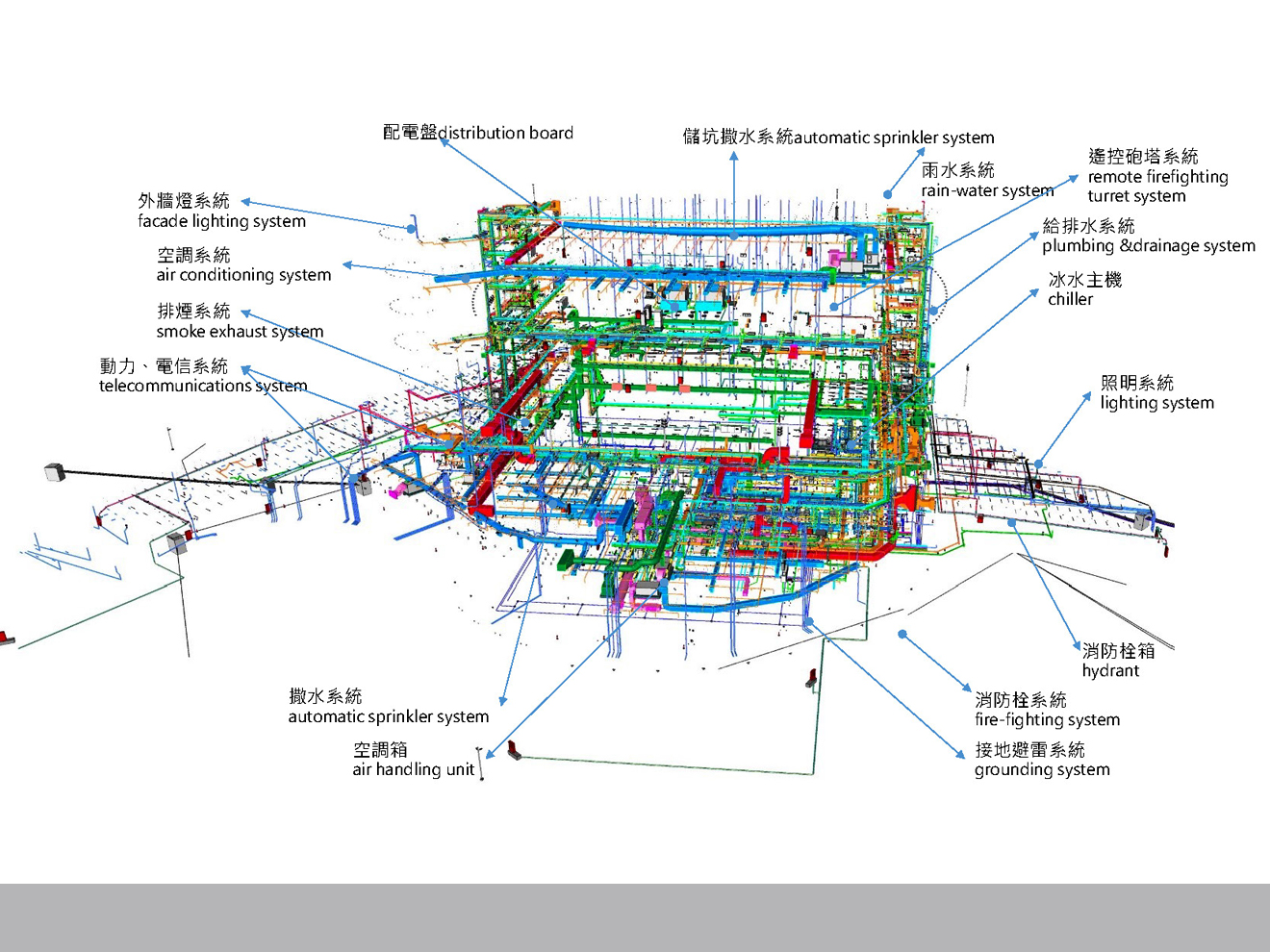

The Taiwan Cement Corporation (TCC) DAKA Renewable Resource Recycling Center (RRRC), located at TCC’s Heping Cement Plant in Hualien County, is TCC’s very own demonstration base for cross-industry resource utilization, zero waste, and low-carbon circular economy, which is also Asia’s first three-in-one “port, power, and cement” circular economy park. As part of TCC’s “open and eco-circular plant,” this facility is scheduled for completion at the end of April 2024. This project is designed and planned by New York-based Kohn Pedersen Fox Associates (KPF) and was honored with the A&D International Design Award in 2021. The scope of works undertaken by CTCI Resources Engineering Inc. (CTCI REI) in this project primarily encompasses construction, steel structure, curtain, and electrical and mechanical (E&M) works for the main building. The main building comprises steel reinforced construction (SRC) on nine floors above ground and reinforced concrete (RC) on one floor below ground, with a building height of 47.2 m, an excavation depth of 11 m, a building area of 10,638 m2, and a total floor area of 26,170 m2. Its exterior walls are made of various types of materials, such as low-emissivity glass, ultra-high performance concrete (UHPC), glass fiber reinforced cement (GFRC), white powder-coated perforated panels, dark gray grilles and rear panels, and dark gray aluminum panels. Meanwhile, the E&M works for this project are commissioned to CTCI Smart Engineering Corporation (CTCI SEC), who is responsible of carrying out E&M works for this project, including power, chiller, general air conditioning, fire protection, water supply and drainage, open sprinkler, and wireless remote firefighting turret control systems.

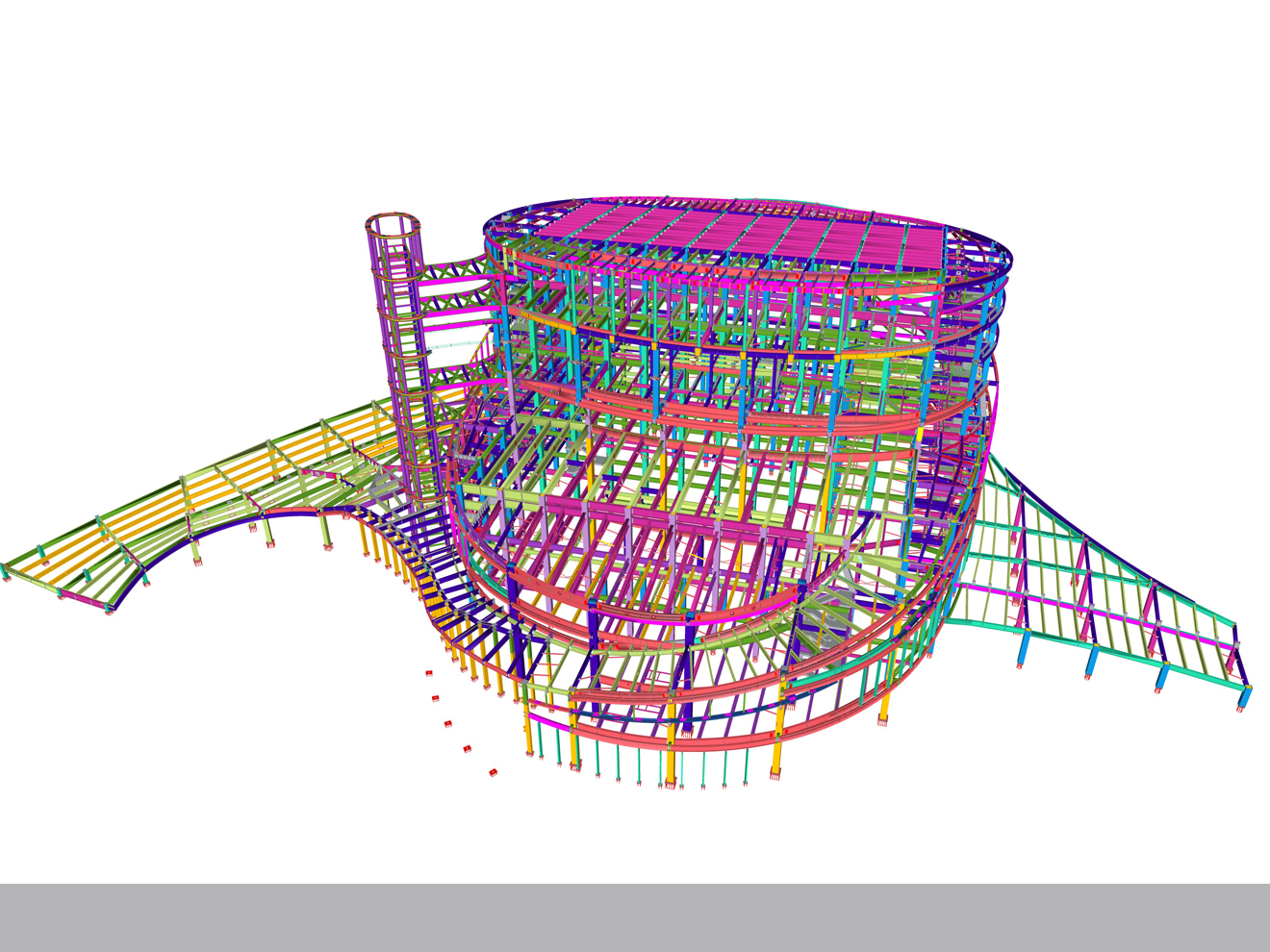

3D design of RRRC

Why CTCI?

Taiwan’s Leading Turnkey Engineering Contractor with the Most Reliable Engineering Quality

CTCI REI, a company under the CTCI Group Intelligent Solutions Business, is Taiwan’s one and only professional civil engineering consulting company that owns an engineering consulting company and a Grade A construction company. With a total of 48 technicians in various disciplines, CTCI REI has accumulated a wealth of engineering experience and technology in the areas of civil construction and transportation engineering. As a leading provider of turnkey solutions for public construction in Taiwan, CTCI REI has received 16 Public Construction Golden Quality Awards and 6 Construction Golden Safety Awards for a series of public construction projects it has undertaken over the years. On the other hand, CTCI SEC, another company under the CTCI Group Intelligent Solutions Business, is a leading supplier of E&M equipment and services in Taiwan, whose scope of business includes the construction of high-tech factories, high-rise buildings, and public infrastructure. While rendering intelligent engineering services for project owners, CTCI SEC also specializes in the construction, improvement, and decommissioning of nuclear power plants, gaining an excellent reputation for high-quality services in power markets both in Taiwan and abroad.

Reliable Realized

Accurate Budget Estimation with Precise Schedule Control

As cost-plus pricing is adopted in the contracting model of this project, the budget is the key control point for the project owner. Despite a series of macro environmental factors, such as soaring construction costs, labor shortages, and the COVID-19 outbreak in Taiwan, directly affected project costs and progress during the project period, the CTCI team showed its culture of professionalism and integrity alongside the spirit of perseverance by making accurate estimates based on market conditions, analysis of trends in rising prices, and transportation demand in Hualien and Taitung, so that the project owner can have control over the budget of this project and minimize the impact of rising building material costs. As far as control of construction progress is concerned, multiple areas of work and various work items are carried out simultaneously, where personnel, machinery, and materials are deployed effectively with professional, meticulous, and efficient control of construction procedures aimed at overcoming the impact of labor shortages. On the issue of COVID-19 control measures, the CTCI team has drawn up a host of on-site management measures while ensuring the implementation of risk control.

Project Highlight

Practicing Circular Economy with Green Engineering

Aerial view of RRRC (under construction)

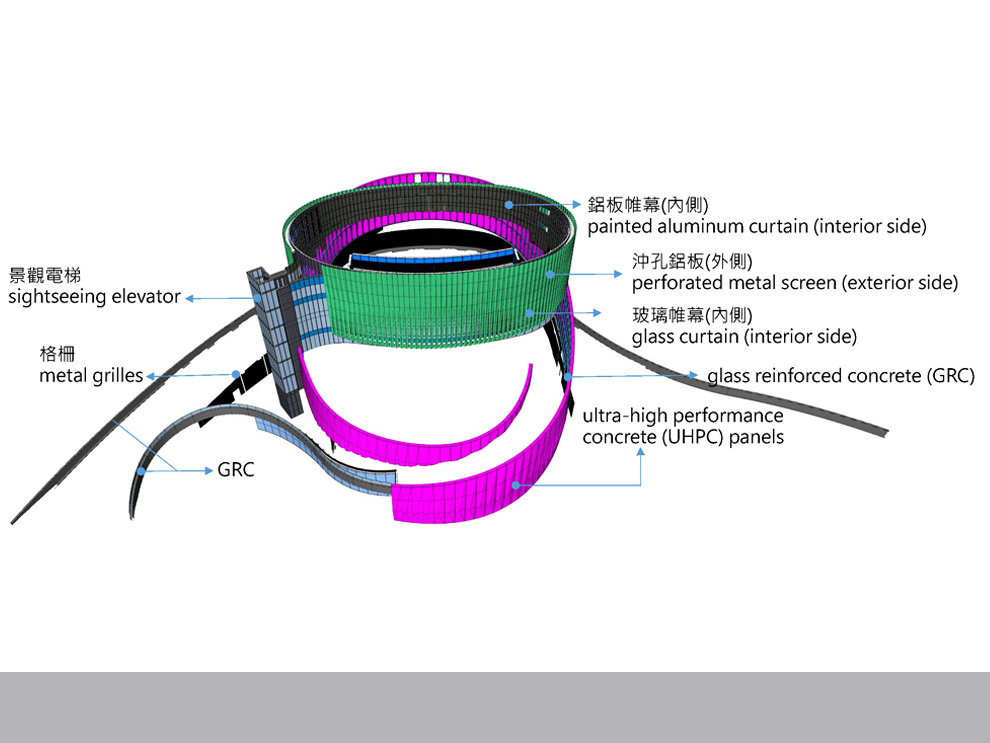

I. Practicing the Concept of Circular Economy This project is the first building in Taiwan that carries out high-temperature waste treatment using a gasifier and cement kiln. Unlike traditional incinerators whose incineration temperature ranges between 850 and 900C only, the cement kiln has a maximum temperature of up to 1,800C, which is sufficient to decompose nearly all substances to nothing when incinerating general domestic waste. Hence, the situation where 20 to 25% of bottom ash and fly ash remain during waste incineration using traditional incinerators does not occur in this facility. The problem of liquid waste treatment and discharge does not exist as this project adheres to the concept of circular economy, where residual bottom ash are used as raw materials for cement-making. Moreover, gasified waste can also be channeled to the production and operation of the cement kiln incinerator and serve as a substitute for raw materials and fuel, thereby saving energy resources in an effective manner. After the completion of this project, this facility can not only effectively fix the waste problem in Hualien, but will also be transformed into a technology landmark and a demonstration site that combines waste resource recycling, environmental education, tourism, and culture, thereby promoting co-existence and co-prosperity in the local area. II. An International Landmark Building with Unique Exterior Design The main building in this project is 47 meters tall with a structure comprising the first basement floor up to the 9th floor, which are mostly high-ceilinged and built using the SRC system. As it serves as a facility for both tourism and waste treatment, the floor partition in this building is complex and must be airtight, while the building is decorated with an ornamental spiral-shaped exterior design supported with curved steel beams and high and low structural panels. Specifically, the 2D arc beam weighs about 1,138 tons, accounting for 14.35% of the total weight of the steel structure in this building. The arc beam is first validated with 3D model in shop drawing, then manufactured at shops, passes inspection and quality control, before being hoisted and installed on-site through meticulous traffic flow arrangements. Each step makes the entire building more complicated and difficult to construct than that of traditional plants. The exterior of this building is constructed based on a curtain system that involves the use of ultra-high performance concrete (UHPC) panels, aluminum panels, glass curtains, perforated aluminum panels, grating systems, and glass reinforced concrete (GRC) modules. UHPC panel, in particular, is a special building material used in this project. With each panel weighing around 2.2 tons, this building material is developed by the project owner exclusively for this project, where its mold is made by a manufacturer commissioned by the project owner. The CTCI team also performed wind and rain testing and other related tests on the UHPC panels to help the project owner verify the safety and durability of this building material so that it can withstand positive and negative wind pressures of 6 kPa. Owing to the fact that the curtain system is ring-shaped and involves a distinctive style, most of the panels differ slightly in terms of design due to the use of curved surface. In fact, curved curtains cover an area of about 15,000 square meters, accounting for 70% of the area of the entire curtain system. With each curtain unit having a different normal direction, its interface and constructability with steel structures have to be taken into consideration in the construction process, thereby posing a relatively high degree of technical difficulty in this project. Thanks to continuous review and refinement from both the CTCI team and professional manufacturers, the architecture of this international landmark building has been completed successfully and smoothly. A visual model has been planned for this project to ensure that the outcomes of the construction of the main structure and exterior of this building meet the resulting design. Taking into account the spirit of sustainability and local characteristics, the CTCI team proposed to the project owner for deliberation that the temporary visual model be developed into a permanent architectural model for display purposes.

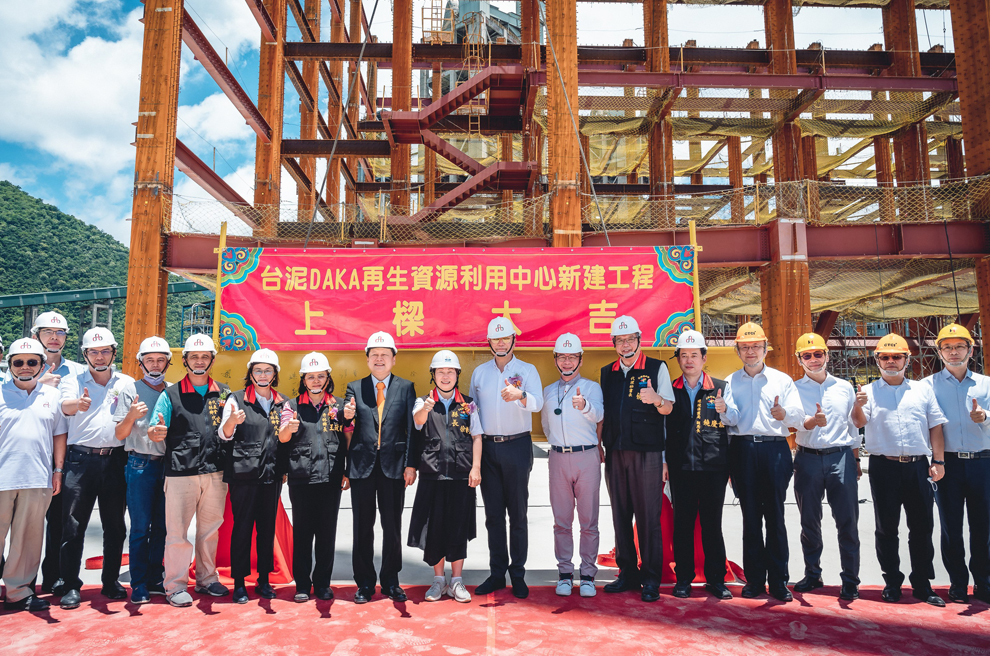

Construction of the structure of RRRC

This project was originally scheduled for completion in April 2024, with a total construction period of 34 months. However, as an act of giving back to the local community, the project owner made a commitment to the Hualien County Government that waste incineration will commence at the facility starting in June 2023. In response to this requirement, the CTCI team has deployed additional manpower to catch up with the construction progress. Thanks to the division of labor between the project and on-site teams along with concerted efforts made by them, the CTCI team managed to overcome severe labor shortages in the local construction industry and hand over the structural foundation to the site ahead of schedule. Furthermore, thanks to a series of proactive efforts such as adjusting zonal construction planning and coordinating simultaneous construction works with steel structure, RC structure, curtain, and equipment manufacturers, the beam-raising ceremony was carried out on June 30, 2022, with the expectation that the target set by the project owner can be met successfully. This project becomes a concrete example of CTCI Group’s vision of becoming “the world’s most reliable engineering service provider.”

Beam-raising ceremony for RRRC

Smarter Engineering

Optimized Design and Interface Integration with the BIM Collaboration Process

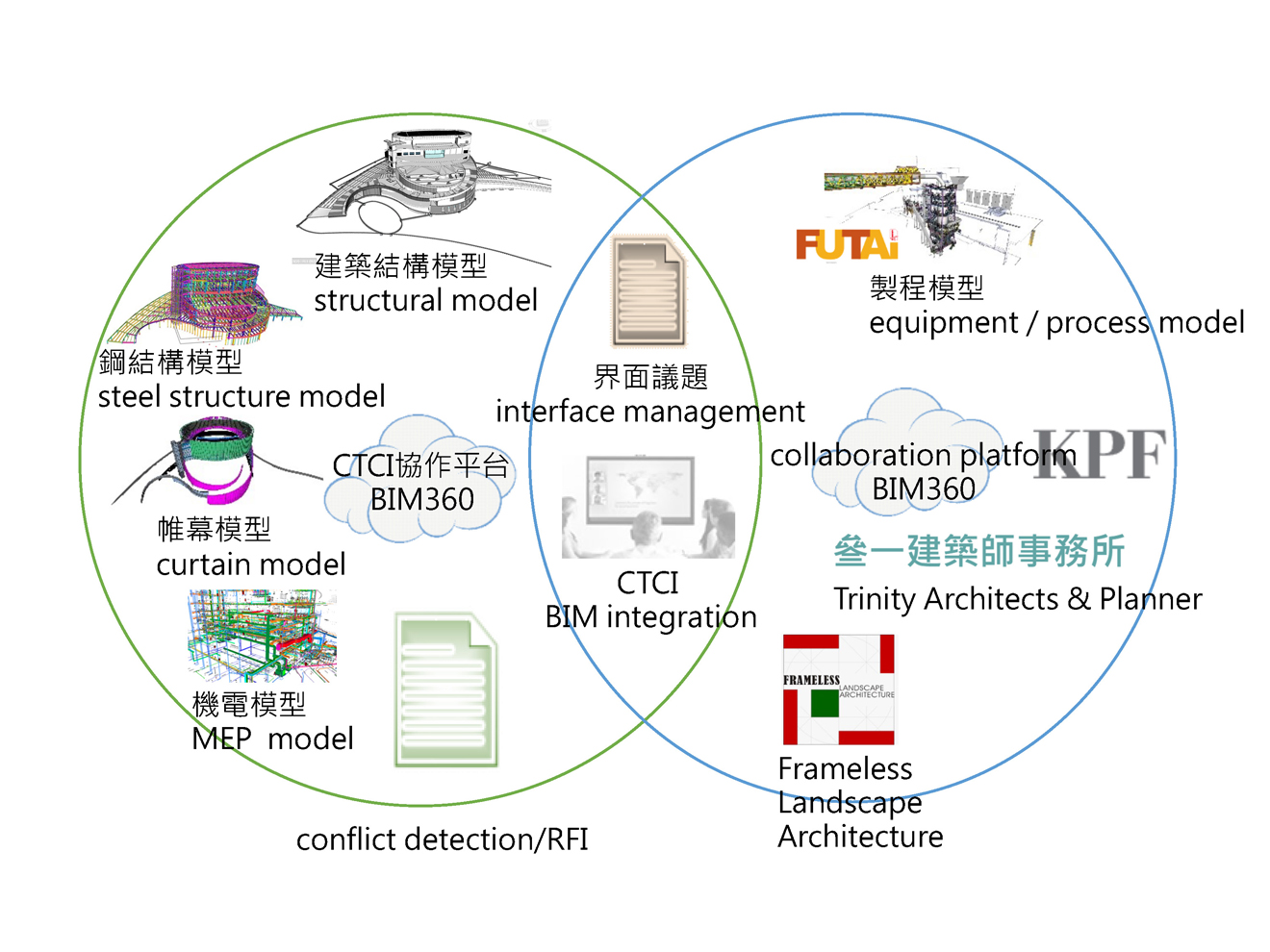

Having been honored with the A&D International Design Award in 2021, this project will become an international landmark upon completion. During the construction of the main building in this project, CTCI REI utilizes the rapid 3D modeling technology on the BIM 360 collaboration platform to help the project owner check during the design process if any conflict exists in drawings and to seek optimization. Such technology also allows integration of interfaces from parallel subcontractors during the construction stage. On top of that, CTCI REI enhances construction management efficiency through BIM technology, which includes saving the content of drawings in various documents, revising version records, and adjusting change management. As cloud operations can boost work efficiency and speed as well as automate the BIM process, the project owner, design units, and parallel contractors can participate in the process and share their progress, which not only realizes the contracting spirit of the general contractor, but also ensures that the project is initiated and executed in an efficient and correct manner.

BIM 360 collaboration platform model

Conducting Carbon Footprint Inventory to Apply for Low-carbon Certification

Following the international trend of net zero emissions, the project owner has engaged CTCI REI to conduct a carbon footprint inventory for this project and apply for the Low Carbon Building Alliance (LCBA) Building Footprint Certification. The carbon footprint inventory for this project was carried out under the guidance of and verified according to ISO 14067:2018 stipulations, which concerns the greenhouse gases assessment and verification for the lifecycle. The scope of inventory is the structures of the RRRC building and the equipment that makes the basic functions of the building complete. Since the lifecycle of the SRC building in this project is 60 years, the scope of inventory and verification covers various lifecycle processes of the building, including the raw material acquisition stage, the construction stage, the building utilization stage, the repair and renewal stage, as well as the demolition and abandonment stage after 60 years as projected based on the current status of the building. The verification process for this project is planned to be completed within the proposed schedule and scope. In so doing, this project will be granted the ISO 14067:2018 Standard Verification Opinion Statement, making it become the first project undertaken by CTCI in which a carbon footprint inventory is conducted while construction is still in progress. It is expected that with the assistance provided by academic institutions in improving the verification method, the CTCI team will be able to gain relevant experience and set a new milestone in the carbon footprint inventory work.

Message from the Owner

The CTCI REI team has been able to fulfill overall environmental safety requirements and provide fast and effective response, which in turn boosts the construction progress. Direct communication between both parties enables problems to be raised and resolved. CTCI REI’s construction team demonstrates excellent technical capabilities in this project. Even though the construction process was affected by the weather, the team still managed to catch up with the progress of the project. The team has been able to fix any problem thrown at them. As such, CTCI REI is indeed reliable. --Chia-Hsin Chang, Manager at Heping Plant, Taiwan Cement Corporation