Technology

技術分享

iSteel: Management and Control of Steel Fabrication

— Roger Yang, R&D Engineer at Civil & Building Engineering Department, CTCI Corp., Group Engineering Business

In an era of advanced information technology and Industry 4.0, an engineering, procurement, and construction (EPC) turnkey project has many interfaces and faces high complexity. CTCI is committed to developing an intelligent EPC platform, which digitizes information and applies it to EPC projects. This helps enhance the capability of project integration, as well as differentiated and agile management, thereby improving project quality. Steel management is an indispensable part in any EPC project. From design, procurement, fabrication, shipping to installation, every stage requires a lot of manpower to implement and manage the details. This article introduces iSteel, a system developed by CTCI for digitized and automatized management of steel structures. It allows information to become transparent for fabricators, reduces interfaces, promotes vertical integration, and increases accuracy and efficiency.

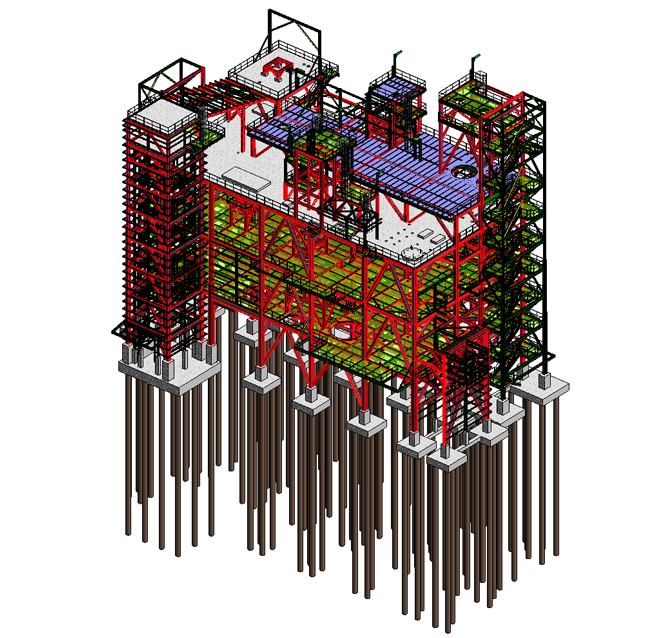

Steel Structure in BIM Application

BIM, also known as Building Information Modeling, is a way of integrating project-related information through parametric models, as well as sharing and transmitting such information throughout a project life cycle that includes planning, design, construction, and operation and maintenance. BIM enables engineers to correctly understand and efficiently respond to various building information, and provides a basis for project teams as well as all parties— including owners— to work together. It plays an important role in improving production efficiency, saving costs, and shortening construction periods. With multiple features such as visualization, parameterization, digitization, coordination, simulation, optimization, and drawing, BIM is a compelling technology. In the design stage, CTCI uses Revit to build CSA (Civil/Structure/Architectural) and MEP (Mechanical/Electrical/Plumbing) BIM 3D models. The steel structure part is converted into the TEKLA Structures model commonly used in the detailed design, and developed into fabrication model for making shop drawings and erection drawings. After completion, the information is fed back to the iSteel system, which is the basis for subsequent management.

BIM Model in the Design Phase(Revit)

Installation Batch

In order to detail the management of steel structures, each structure is divided into different installation batches (IB). Each fabrication step is then planned according to the IB's schedule. Meanwhile, the information is embedded in the BIM model and connected with iSteel management.

Cost Control

Cost control is an important item of project management. As soon as iSteel gets bill of materials (BOM) from the steel structure shop model, it automatically generates the assemblies list, pieces list, and bolt list, all with accurate quantities that meet the measurement standards and correspond to the detailed contract items. This not only allows real-time control over budget and contract quantity during the project execution process, but also allows accurate data provision during settlement to ensure cost control.

Raw Material Purchase Management

The raw materials of steel structures include things such as shape steel, steel pipe and steel plate of different sizes, specifications, and materials. To ensure a sufficient amount of steel required for fabrication based on an IB plan, iSteel would automatically generate a raw material quantity control table to check both current and future material arrivals.

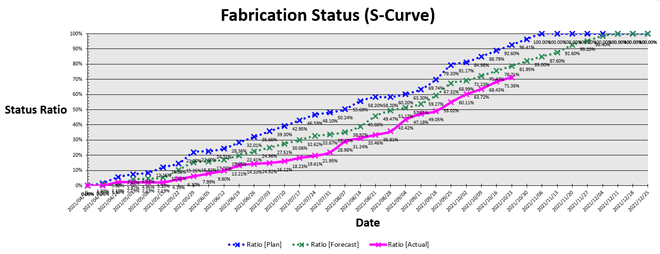

Progress Management

Progress management is an important topic for engineers. The aim is to help engineers keep track of each project sub-operation’s progress during the entire EPC period to ensure the project is completed on time. For steel structures to be installed on schedule, it is necessary to accurately keep track of each fabrication step. The steel fabrication steps include cutting, assembling, welding, galvanizing, painting, packaging, and shipping. iSteel would compile fabrication progress data and automatically generate control reports, keeping manpower to the minimum and processes standardized.

Fabrication progress (S-Curve)

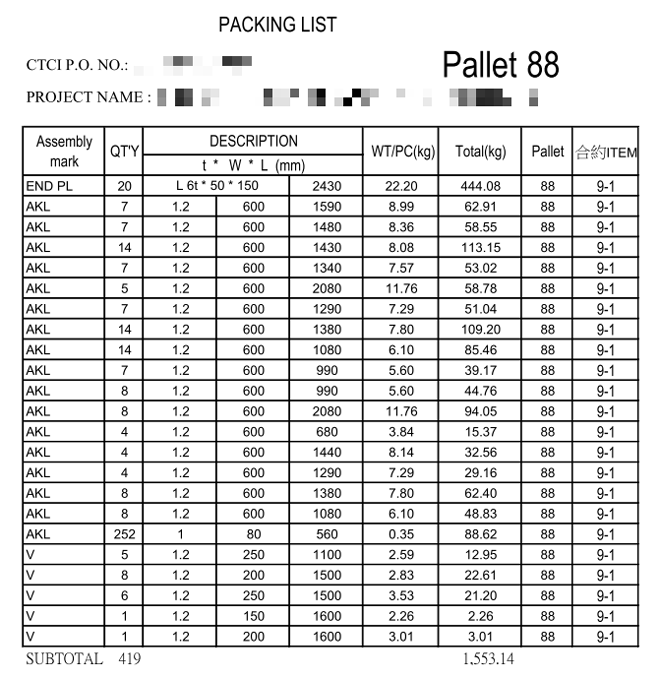

Delivery Management

Once fabrication is completed, the ensuing work such as packing, inspection, marking, shipping, and warehousing must be thoroughly implemented. For all aspects to be organized and managed in an integrated manner, iSteel has integrated the planning, material information, and fabrication progress. Moreover, QR code was introduced to the shipping process. The integration with the warehouse management system allows iSteel to replace paperwork and successfully achieve digitalization, automation, and intelligence.

Packaged steel structures ready for delivery

The introduction of QR code allows packing list to be generated quickly

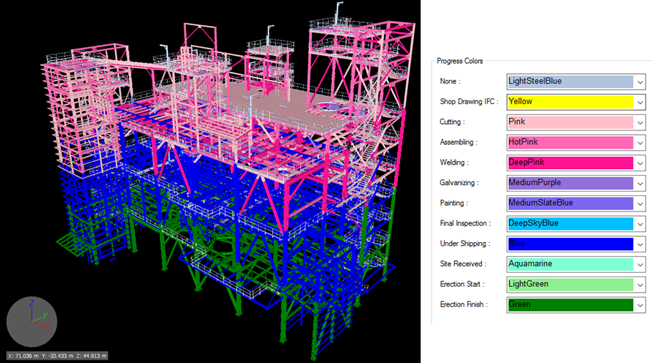

3D Display

Nowadays, traditional 2D drawings and charts can no longer meet users’ needs, and 3D visualization has become the mainstream. By connecting the BIM model and iSteel, information such as fabrication status, shipment, and installation can be visualized, becoming clearer and improving efficiency.

Steel assembly status is displayed in different colors

Conclusion

In a world of booming intelligent technologies, traditional labor-intensive way of operations can no longer meet the needs of industries. The iSteel system discussed in this article can integrate engineering information at all stages, and has been applied in multiple projects, effectively saving engineers’ time in collecting information, organizing and analyzing data, and allowing engineers to quickly identify problems. iSteel offers high-efficiency and high-precision control, and can be integrated with the material management system, warehouse management system, and construction management system. This is a part of CTCI’s active effort in advocating for iEPC, where automation and intelligence are introduced to EPC projects. With innovative EPC management thinking, CTCI will continue to aim for a vision that sees EPC become smarter and more digitalized.