Discover Reliable

發現信賴

CTCI Successfully Builds the Core Electromechanical System for Taichung Metro

-- Taichung Metro Wuri-Wenxin-Beitun Line Electromechanical System Installation Project

— Edward S.C. Young, Project Manager & Benson, Jun-Ren Lou, Project Manager, CTCI Corporation, Group Engineering Business

- Market:Transportation

- Owner:Taichung City Government/Electrical and Mechanical Design Division, Department of Rapid Transit Systems, Taipei City Government

- Executive team:KAC (KHI-Alstom-CTCI)

- Completion time:Mar. 2, 2022

- Project location:Beitun District, North District, Xitun District, South District, and Wuri District, Taichung City

- Project Scope:Electromechanical integration management, electric multiple units, train monitoring, power supply, communications, automatic payment, and depot maintenance equipment

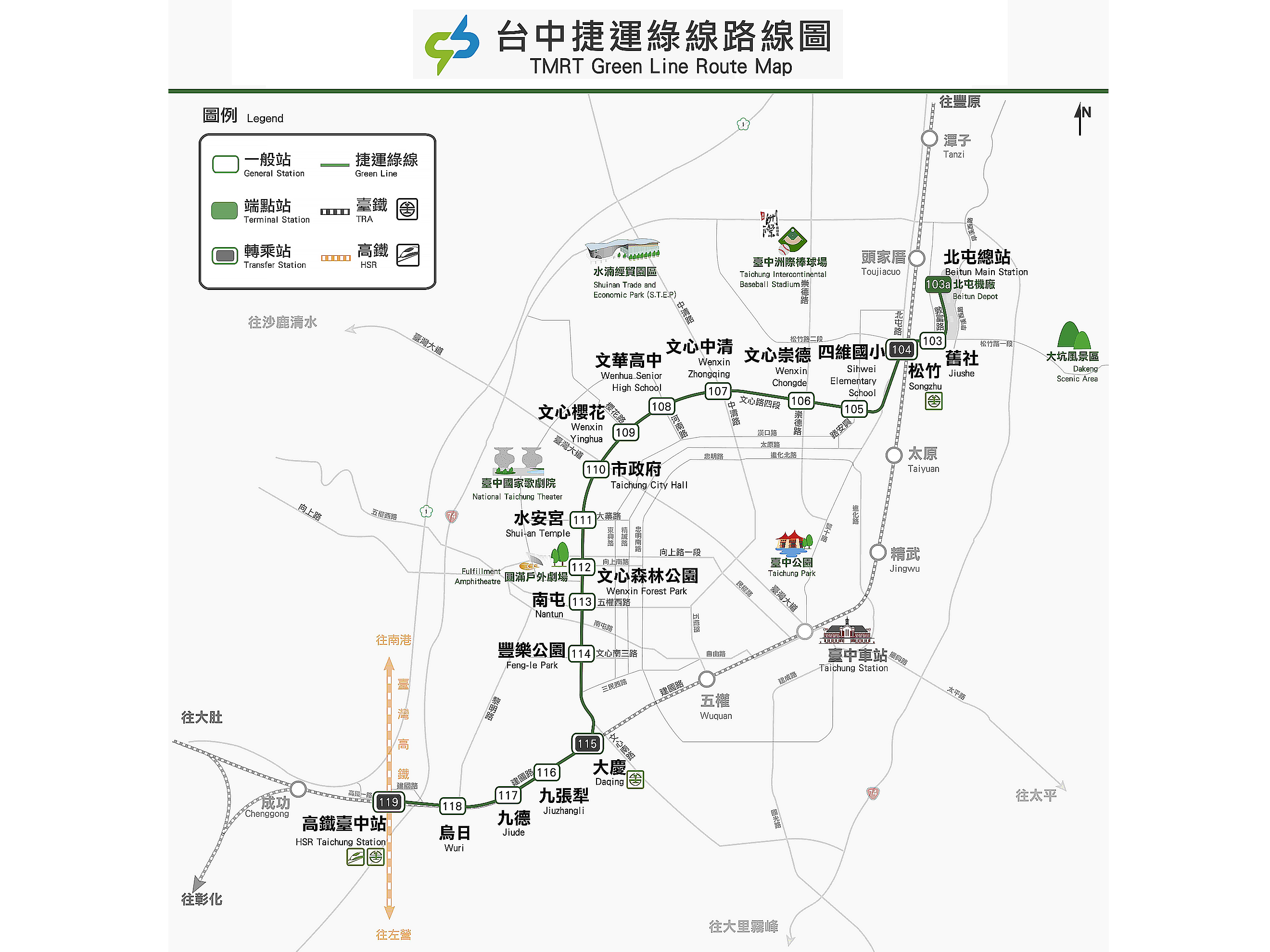

The Taichung Metro Green Line was the first line constructed and operated for Taichung Metro. It uses steel wheel, and is a medium-capacity rail system. Apart from the Beitun Terminal Station and Taichung HSR Station being on ground level, all other sections and stations have adopted elevated designs. The route passes through Beitun District, North District, Xitun District, South District, and Wuri District (the extended line includes Changhua City in Changhua County). The line forms a circle route with TRA Taichung Line between Songchu Station and Daqing Station. The Wuri-Wenxin-Beitun Line is the main route of the Green Line and the earliest line to begin service. Taichung City Government commissioned the Mechanical Design Division, Department of Rapid Transit Systems, Taipei City Government to conduct selection and contracting for the electromechanical system of the project. The KAC (KHI/Alstom/CTCI) Team, consisting of Kawasaki Heavy Industries, Alstom SA, and CTCI, used its excellent techniques and experience to rise above the competition and win the bid. The KAC Team was responsible for the design/assembly/testing of the system. The entire line is 16.71km in length (15.94km of elevated sections and 0.77km of ground level sections). There are 16 elevated stations (from Jiushe Station to Wuri Station) and 2 ground level stations (Beitun Terminal Station and Taichung HSR Station), totaling 18 stations on the line. The Beitun Depot was established with level 5 maintenance functions.

Why CTCI?

Excellent Electromechanical Integration Capabilities

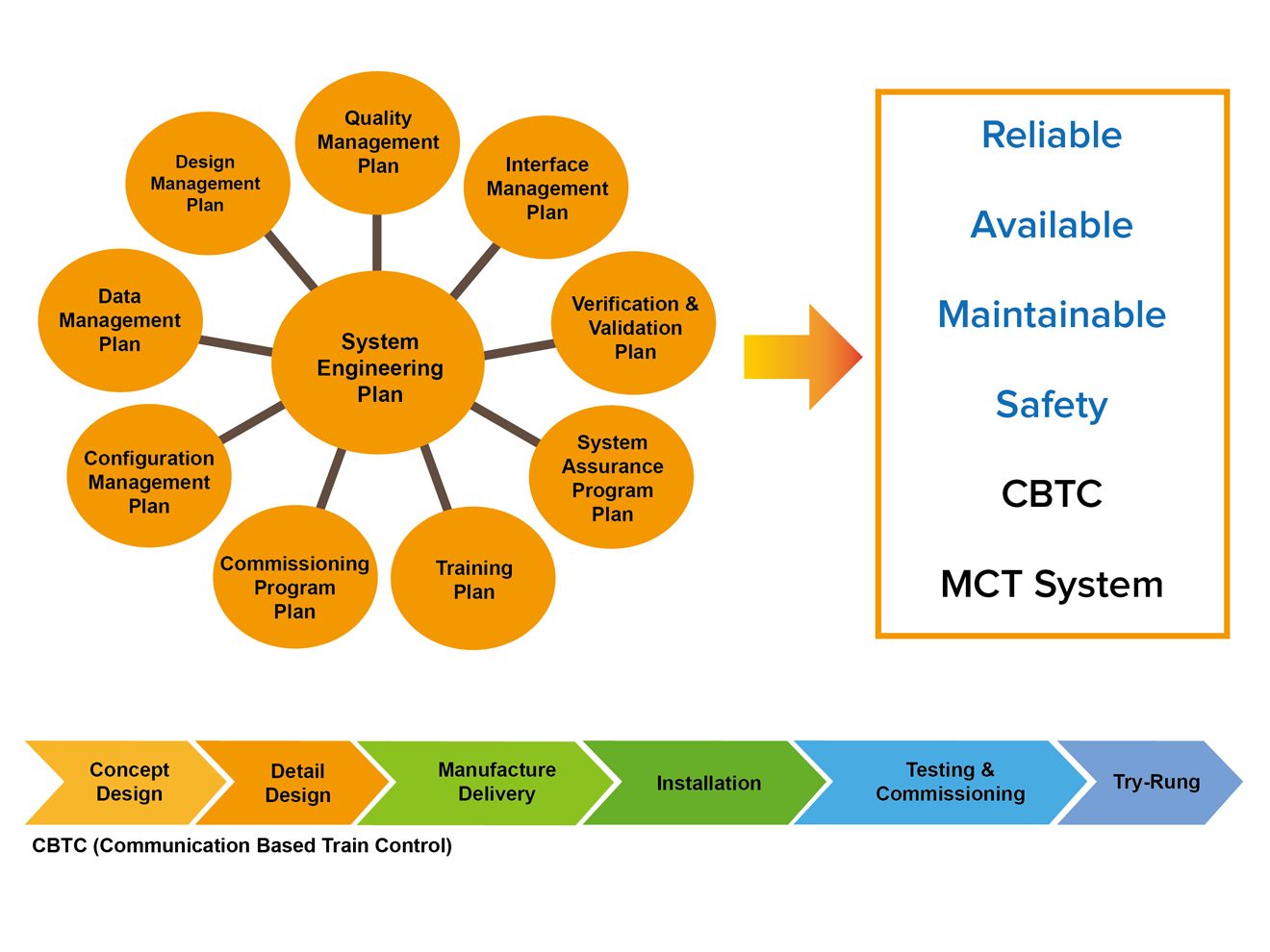

CTCI formed the KAC team with Kawasaki Heavy Industries and Alstom SA. Besides their excellent performances in various subsystems, the team's commitments and track records on electromechanical system integration were also winning factors for securing the bid. The KAC team includes RAMS (Reliability, Availability, Maintainability, and Safety) disciplines in the plan execution phase and integrates RAMS in a complete Project Management Information System (PMIS). The KAC team has also built the Project Requirement Allocation Traceability (PRAT) platform to conduct the project management and system integration for the electromechanical system. Since engaging in the Xinzhuang-Luzhou Line electromechanical project of the Department of Rapid Transit Systems, Taipei City Government in 2003, CTCI has become the biggest metro electromechanical system contractor in Taiwan. Besides providing installation for electromechanical systems and subsystems such as power supply, tracks, communications, and automatic payment, CTCI also actively engages in the project management and system integration work for the entire electromechanical system. The Wenxin-Beitun Line of the project is the third case of CTCI participating in project management and system integration, and CTCI is securing more systems engineering and integration works for metro electromechanical projects.

System engineering and integration schematics.

Reliable Realized

Combining Cross-disciplinary Experts to Create Win-win for the Contractors and Owners

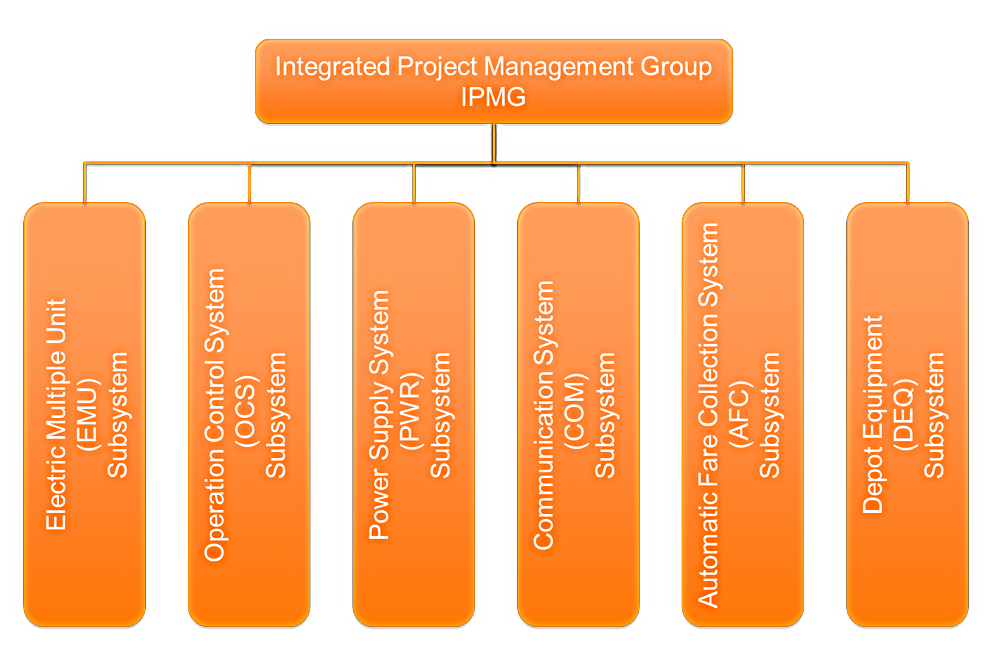

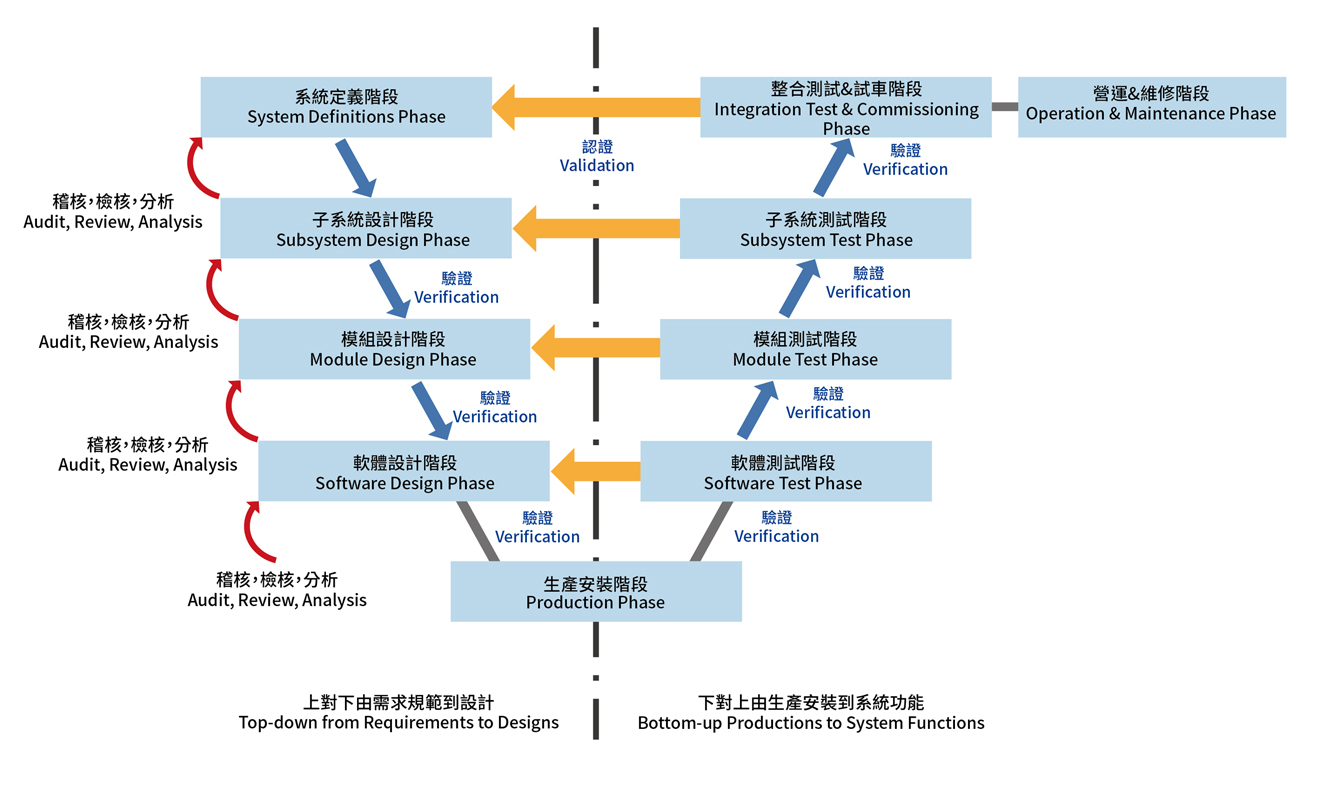

"Systems engineering and integration" is a disciplined approach that combines the expertise from different disciplines and rallies the expertise and experience of various work teams, in order to build an integrated and comprehensive system. The concept is to strike a balance between system functions, risks, time, and costs factors, to create a win-win situation for project owners and contractors. In terms of the metro electromechanical system, "systems engineering and integration" refers to the construction of a complete metro system through the combination of electromechanical subsystems, such as electric multiple units, train monitoring, power supply, communications, and automatic payment, and depot maintenance equipment and tracks with civil and station building engineering, in order to meet the functional requirements of the owner. This part of the project was executed by the Integrated Project Management Group (IPMG). A hierarchical system design was adopted to ensure the consistency of the interface technologies in the overall electromechanical system and the different subsystems, and to satisfy the requirements for RAMS, and human factors engineering. The operations related to each subsystem, such as design, production, manufacturing, and testing, are executed on the subsystem levels. The expanded structure of the system engineering and the lifecycle described above is shown in the figure below.

System engineering and lifecycle.

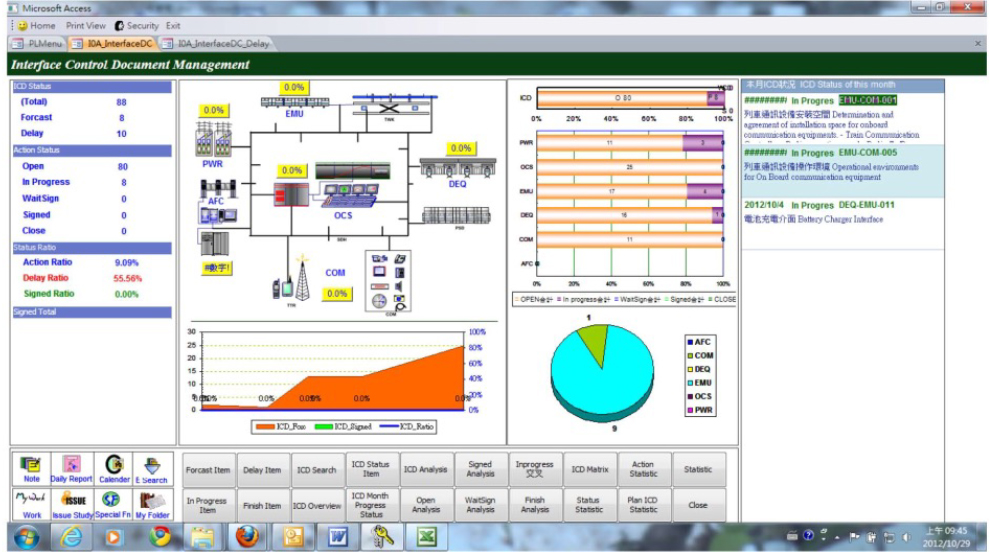

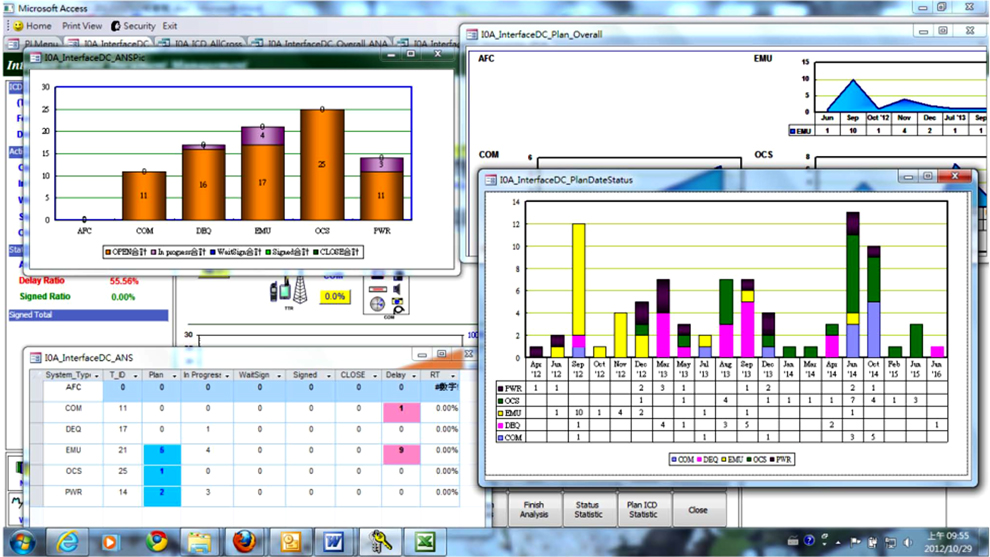

Project Highlight

Comprehensive Project Management Information System

The system integration and management of the metro electromechanical system are primarily based on the integrity of Project Management Information System (PMIS). Our team took advantage of the PRAT platform to handle the system integration issues related to the project between the IPMG and the various subsystems. Using the Interface Control Document (ICD)—a typical document of the metro electromechanical system)— as an example, apart from providing the main ICD monitoring screen, the PRAT platform also visualizes the ICD status of various subsystems, as shown in figures below.

Smarter Engineering

The First Automated Metro System in Greater Taichung

The electric multiple units (EMU) of the Taichung Metro Green Line are the first to adopt the GoA4 (Unattended Train Operation) metro system in the greater Taichung area. The system is fully-automated, requiring no on-train staff for the activation of the train, stops, door opening and closing, and even for handling different emergencies as these are controlled from the central control center.

Taichung metro electric multiple units (Photo source: China Times).

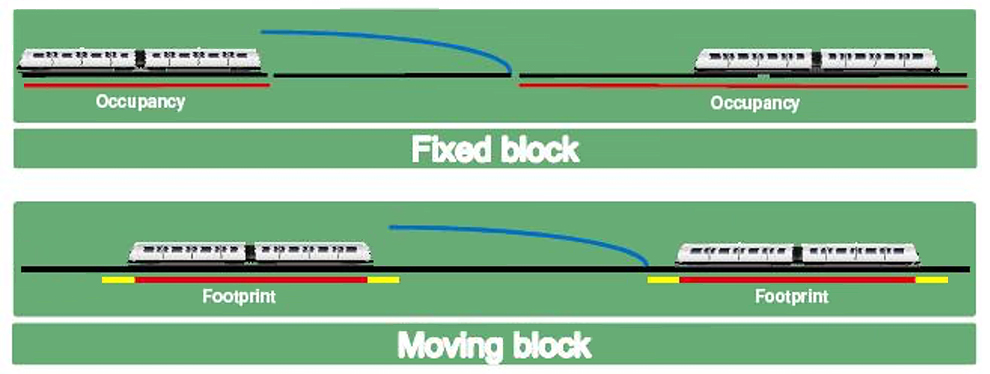

Furthermore, the train monitoring system in use is the Communication Based Train Control (CBTC) system, which connects the train and track-side equipment to continuously track the train's location on the track with high precision (margin of error of less than 10 meters) without the need to rely on track-side circuits. Compared with traditional fixed-block systems, CBTC has a significant advantage in terms of accuracy. Differences between the two systems are shown in the figure below.

Fixed block signaling system vs CBTC system (moving block).

With the success in the execution of the Taipei MRT Xinzhuang-Luzhou Line, Xinyi-Songshan Line, and Taichung Metro electromechanical system projects, CTCI has secured contracts for the Taipei MRT Wanda Line First Phase, Wanda Line Phase 2 metro extension, and Circular Line electromechanical system projects in 2018, 2020, and 2021, respectively. Currently, the projects are on schedule to meet our targets. As the number one and most reliable metro electromechanical system contractor in Taiwan, we at CTCI will continue to invest heavily in track transportation with our core engineering capabilities, to provide convenient, safe, and inviting metro systems to the public and contribute to the development of city infrastructure. --Johnny Chuang, General Manager at Transportation Infrastructure Department, CTCI Corp.