Sustainable Future

永續未來

Application of OHS Technology in Engineering Industry

─Daniel Ting, Senior Manager, HSEM Dept., CTCI Corp., GEB

The rapid development of artificial intelligence, Internet of Things, cloud and other digital technology in the recent years has not only continued to change people's lives but has also become a driving force for industrial progress. CTCI, as the largest turnkey engineering company in Taiwan and the world's top 100, has contracted projects all over the world. As the executed projects become more and more complicated, the potential disaster risks on the construction site are also increasing. This article uses occupational health and safety (OHS) risk control examples both internationally and at CTCI to illustrate how the engineering industry can improve OHS management capabilities and reduce the occurrence of occupational incidents with the aid of new technologies.

Application of Digital Technology in OHS Management

Information technology and communication technology had been classified into two different fields in the past. Information technology (IT) is a technology that collects, processes, and stores data, such as voice, image, text, and numbers, and is mainly used in computer design and development. Communication technology (CT) is the technology of disseminating information, such as network exchange, wireless communication, and mobile communication. In the field of ICT (information and communication technology), information technology is used to encode and decode, while communication technology is to spread information. With the development of technology, these two has become inseparable. According to the report by the Japan Construction Industry Labor Accident Prevention Association, ICT technology can also be applied to construction projects, for instance, installing sensors on transport vehicles so that the transport vehicles can calculate the load weight at any time, and manage in real time through devices such as tablet PCs or smart phones to prevent extended braking distances or road damage caused by overloading, so as to ensure transportation safety. The Japanese construction industry has also used the same technology to develop the "T-iDigital Field" system to solve the problem of personnel intrusion into the lifting area and manage the movement of workers on site. In terms of intrusion prevention for lifting operations, the positioning system installed on the tip of the crane boom and the GNSS (Global Navigation Satellite System) on the operator provide data and images, allowing the system to perceive approaching objects below the lifting area. When the system perceives people approaching below the lifting area, the monitor and voice system of the crane driver's seat and the smart watch on the flag man will issue an alarm to warn of possible impending high-risk behaviors and eliminate the danger in time. In addition to preventing personnel intrusion in the lifting area, the same technology can also be used in personnel and machinery management. The system collects the location data of engineering tools and workers, such as traffic flow, detection of intrusion area, location of engineering tools and whether they are close to any personnel, and speeding. Based on these data, it is possible to identify engineering tools and personnel with dangerous or unsafe operations, and propose procedures and actions that can reduce these risks.

Safer, More Advanced OHS Management with Digital Technology

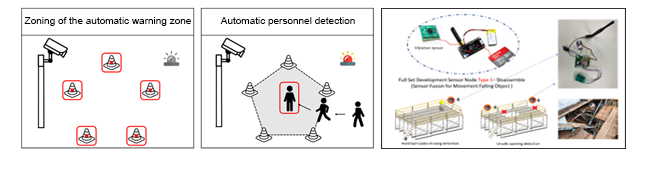

According to statistics from the Ministry of Labor on the number of casualties in domestic occupational hazards from 2004 to 2019, the largest number of construction occupational fatalities are due to "falling or falling over." The major causes include personnel failing to use personal protective equipment properly and unsafe openings. Since lifting operations are common operations at the construction site—and it is not rare for construction site personnel to accidentally enter the lifting area—the severity of the hazard triggered from misoperations cannot be underestimated. The effectiveness of preventing accidents, however, is quite limited if we depend solely on traditional occupational safety management or education. In order to improve the quality of OHS management and to further reduce the occurrence of industrial safety accidents, the CTCI HSE team has kept pace with the latest trend in digital technology and developed site safety management tools. At the initial stage, the focus is on hazard identification and analysis of “guardrails and covers for unsafe openings on construction sites” and “personnel accidentally entering the lifting area,” with the aim to develop an automatic detection and notification system. It is expected that through the system, onsite management personnel can supervise operations and prevent violations or accidents from happening on site. As for protection of unsafe openings on the construction sites, CTCI team has researched and developed an active detection and notification system for protective covers and guardrails. Sensors are set up on the guardrails or protective covers of any openings in scaffolding or high places above 2 meters. When the guardrail or cover is removed or moved, the sensor will activate the instant message notification system and alert supervisors to notify relevant personnel to back away or improve the on-site environment to achieve the effect of deterring violation. Regarding the prevention of personnel accidentally entering the lifting area, a warning zone and automatic detection system will be developed and set up. First, a set of visual identification system will be established to identify the traffic cones and calculate the area surrounding the construction site. The human body identification model will then be used to set conditions for identifying the equipment and the identity of personnel on-site, the system will issue a warning when an unpermitted or unauthorized person enters, while tracking the movement of those who are permitted to enter the area. In addition, this system can issue warnings to inform relevant personnel when people are working or passing under hanging objects to prevent harm or damage caused by falling objects. It can also identify whether personnel in the lifting area are wearing reflective vests, helmets, and other personal protection gear and issue warnings to notify relevant personnel to strengthen construction safety supervision capabilities.

Left and middle: Schematic diagram of the warning zone for lifting operations and automatic detection of unauthorized personnel. Right: Schematic diagram of automatic detection of unsafe openings.

Conclusion

For the current international engineering industry, the application and influence of emerging technologies in OHS management is getting increasingly important. It is worthwhile for related industries in Taiwan to do more in-depth discussion and improvement on how to make good use of technological advantages as a management aid, identify hidden risks and crises by comprehensively reviewing the constant changes of construction sites, and propose opportunities for correction or improvement efficiently. According to the international standard ISO 45001 Occupational Safety and Health Management System, risk and opportunity management is indispensable if an organization desires to improve safety and health performance and reduce workplace hazards. Particularly, technological management is the key to improving HSE performance. CTCI holds fast to the vision of becoming "The Most Reliable Global Engineering Services Provider" and actively promotes the application of digital technology in OHS management. We believe that the establishment of more successful cases and the collection and application of relevant data will help to improve the level of safety in the engineering industry, and continue to move towards the goal of reducing occupational hazards. Reference: Japan Construction Occupational Safety and Health Association