Discover Reliable

發現信賴

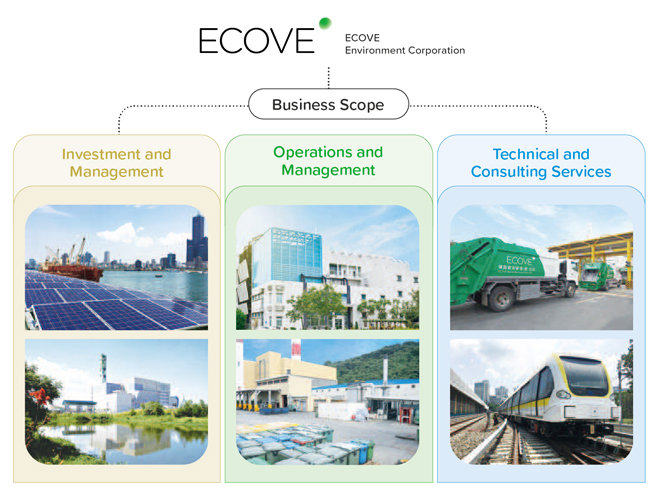

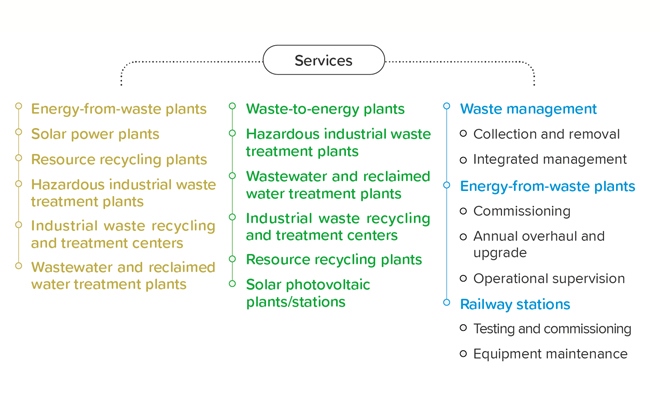

Energy-from-Waste Plant in Miaoli: A Perfect Case of CTCI’s Unceasing Effort to Push for Circular Economy by Turning Waste into Energy

— Pei-Feng Chu, President of ECOVE Miaoli Energy Corp., Group Resource Cycling Businesseration Dept, CTCI Corporation, Group Engineering Business — Yu-Hsuan Peng, Manager of ECOVE Miaoli Energy Corp., Group Resource Cycling Businesseration Dept, CTCI Corporation, Group Engineering Business

- Market:Public construction

- Owner:Miaoli County Government

- Executive team:ECOVE Miaoli Energy Corp.

- Preparation and construction period:Sept 13, 2002 – Feb 28, 2008

- Commercial operation period:Feb 29, 2008 – Feb 28, 2028

- Project location:Haikou Village in Zhunan Township, Miaoli County

- Project Scope:Investment, design, procurement, construction, commissioning, operation

- Designed handling capacity:500 metric tons/day

- Generator set capacity:11.8 MW

Back in the days when Miaoli County Government was faced with waste disposal issues, it opted for incineration and decided to find a qualified constructor and operator based on the Build-and-Operate (BOT) model. The "Regulations on Encouraging Public and Private Institutions to Participate in Constructing and Operating Waste Incineration Plants," on which such plan is based, serves as an incentive for boosting private funds and operational efficiency through BOT. As soon as CTCI was selected as contractor thanks to its rich experience and track records, CTCI established a chartered company called ECOVE Miaoli Energy Corp. to be responsible for the Energy-from-Waste (EfW) plant. Construction was carried out by CTCI, while CTCI’s subsidiary company, ECOVE Environment Services Corp. (ECOVE ESC), is responsible for operating the plant for 20 years. Having been operational since February 29, 2008, the EfW plant’s waste handling capacity is 500 metric tons per day. Since this surpasses the amount of general garbage and industrial waste produced in Miaoli County, the EfW plant can also help process waste from other counties, such as Hsinchu and Nantou. The plant is a fine example of circular economy in action because it can generate power through recovered heat that comes from waste processing, supplying up to 42 days of power to 190,000 households in Miaoli per year.

Why CTCI?

Extensive Engineering Track Records and Capable of Providing Integrated Services

In the early 1980s, Taiwan began to introduce incineration as a measure to deal with the ever-increasing waste. CTCI entered the market early on. It was— and continues to be to this day—the only firm that is capable of investing on and carrying out engineering, procurement, and construction (EPC) for Energy-from-Waste projects in Taiwan. Notable EPC examples include Southern District Waste Management Plant and Renwu Refuse Incineration Plant in Kaohsiung, southern Taiwan. CTCI is also proud to be the EPC firm and the operator for the first EfW plant in Taiwan based on BOT model: Wuri Waste Resource Recycling Plant. Over the years, ECOVE ESC became the operator of eight large-scale municipal EfW plants, while ECOVE Waste Management Corp., another CTCI subsidiary, offers one-stop solution to deal with the many aspects of waste treatment: waste management, waste collection, and turning waste into resources. Thanks to CTCI’s exceptional engineering track records and all-encompassing waste collection and treatment services, CTCI was chosen as the preferred EPC contractor and operator for Miaoli EfW Plant.

Reliable Realized

Attentive Engineering and Excellent Operational Performance

When designing Miaoli EfW Plant, CTCI team not only kept in mind the issues found during the construction and commissioning of previous EfW plants, such as Southern District Plant, Renwu Plant, and Wuri Plant, but also drew upon the experiences of other EfW plant operators. The result is a plant that greatly cuts down the chances of potential equipment failures and shutdowns. It also ensures operations can go interrupted and helps maximize power generation efficacy. Miaoli EfW Plant boasts leading scores in terms of equipment adequacy rate and operational efficiency among 24 EfW plants across the island. For eight consecutive years, it has also been the recipient of either excellent or outstanding inspection performance awards, given by Environmental Protection Administration. This is all due to the hard work of the operations team, which always seeks to improve the adequacy of equipment, operational conditions, and overall status. CTCI’s unrelenting investment in researches of plant optimization and technologies has brought fruitful results: CTCI successfully became the EPC contractor and operator of Taoyuan City Biomass Energy Center and the Changhua Coastal Industrial Park Resource Recovery and Treatment Center, both of which adopt cutting-edge global technologies and enjoy power generation efficiency of at least 25%. These two BOT projects are in line with global standards, be it treatment technologies, energy conversion efficiency, or emission standards, and are prime examples of CTCI’s contribution to the circular economy.

Project Highlight

Keeping the Ecology Intact and Fostering Green Future

Located near the wetlands of Zhonggang River estuary, Miaoli EfW Plant sits on an important habitat for migratory birds and a type of butterfly called Euploea Sylvester. To protect such a place with rich ecology, CTCI not only takes effort in meticulous engineering but also acts as an active environmental educator aiming to foster a green future. 1.Improve the surrounding environment to create an environmentally friendly ecosystem Geologically speaking, the EfW plant site sits close to a barrier flat. Some parts of the site base was originally used for landfill. As a result, the area is prone to land subsidence. CTCI not only needed to remove the landfill waste before construction, but also devised ways to improve the soft-soil geological conditions and adopted foundation piling. To increase the span of wetlands and flood storage area, CTCI cut down the size of the plant and adjusted its configurations accordingly. After the plant came online, the company actively engages in community work, adopts beaches, and takes part in the conservation of Euploea Sylvester. This preserves the integrity of the local ecosystem while taking care of operational efficiency.

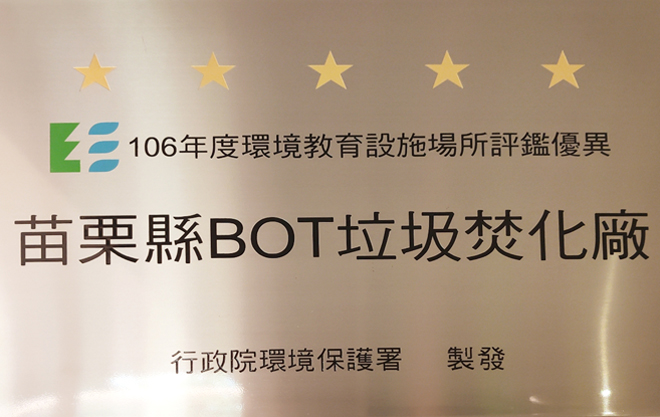

2.Widely recognized for devotion in environmental education In an effort to educate the general public about ecological conservation and waste disposal so that the public will take the initiative to do better things for the environment, CTCI joined forces with Miaoli County Government and transformed the EfW plant into a "Green Dream Plant," allowing the public to immerse themselves in themed figurines, interactive games, and videos, all of which have profound environmental education meaning. Due to the excellent results, the EfW plant was given five-star rating through Environmental Protection Administration's Environmental Education Facility Evaluation, and became one of the top ten most popular environmental education facilities among 219 sites in Taiwan. Miaoli EfW plant also organizes many environmental activities with various stakeholders. It works with local communities in organizing guided tours, which take visitors to learn more about man-made wetlands and the EfW plant. It also works with schools in organizing field trips for junior high school and elementary students as a way to promote environmental protection, ecological diversity, and waste sorting. Thanks to the excellent results, Miaoli EfW was given National Corporate Environment Protection Award (Gold Level) for two consecutive years.

Smarter Engineering

Smart Plant Designs and Optimized O&M Systems

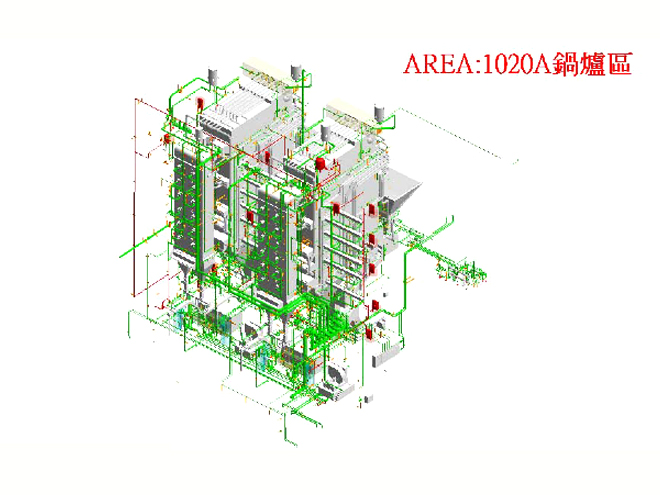

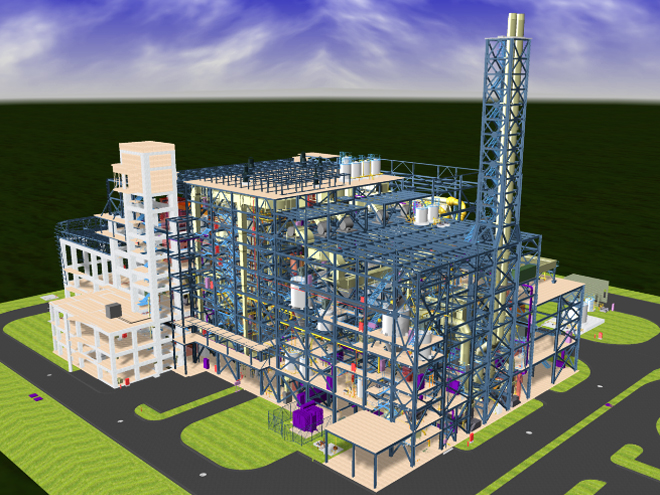

CTCI has long devoted to the research and development of smart features in engineering, or iEPC (intelligent engineering, procurement, and construction). Miaoli EfW Plant is a typical example where smart features have been incorporated into its design and construction. As for Miaoli EfW plant’s O&M, CTCI draws from its extensive experience both globally and domestically in the realm of incineration and optimizes operational efficiency through system enhancement. 1.Smart plant planning and design: 3D model design and 4D construction When designing Miaoli EfW Plant, CTCI utilized 3D models to check whether there is any collision between equipment, piping, wiring, and wire trough. 3D models also allowed the engineering team to preview the actual workspace from the perspective of an operating staff on site and check whether there is enough space between equipment for onsite operations. This not only reduced chances of error from designs and on-site construction interface, but also enhanced design quality and construction reliability, thereby ensuring cost-effective operation and maintenance. It also ensured construction progress and personnel safety, so that the project could be completed on schedule and with quality.

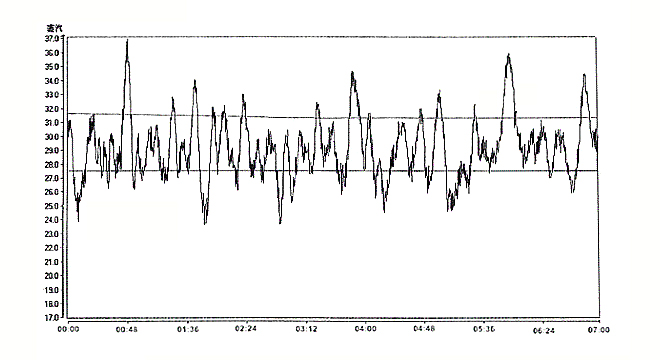

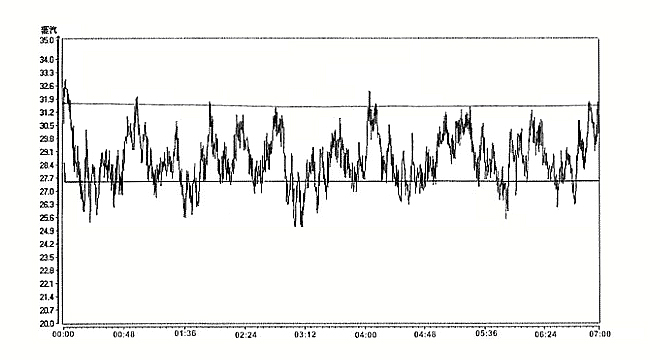

2.Automatic Combustion Control (ACC) Based on years of experience in EfW plant constructions and operations globally and domestically, CTCI has developed an improved automatic combustion control (ACC) system that can ensure more precise output. To do so, CTCI used fuzzy control as the framework and broke down the parameters that affect furnace control according to waste characteristics in Taiwan. CTCI then used statistical tools to analyze the ways of human operations before adapting them into standardized and programmed control rules, so as to reduce chances of error in the future. After a long period of testing, the upgraded system has now reached 95% in terms of reliability, much higher than the original design of any existing EfW plants. Moreover, this system effectively cuts down exhaust and pollutant emissions, as well as significantly improves combustion stability and system performance. It is surely a control system with functionality and practicality.

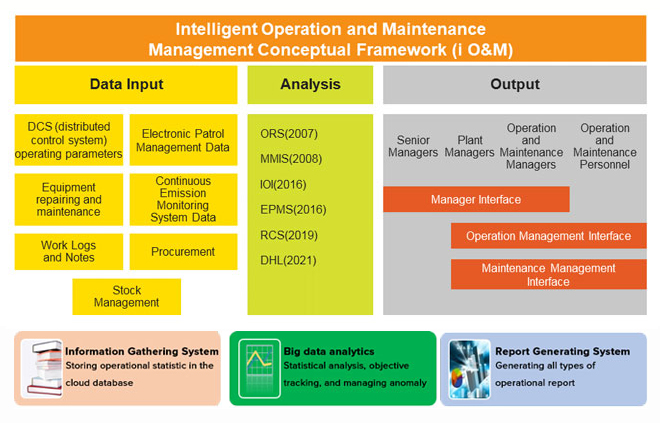

3.Operation Results Management System (ORS) To better manage the EfW plant, CTCI selected operating parameters and indicators that are relevant to EfW operations. The managing staff would compare daily operating data against the management values, design values, and historical data in the management system. After running an analysis, if the system detects an anomaly, the system will automatically send out a reminder so that the management staff can immediately understand the current condition of operation. The analysis can also be used by onsite personnel to make adjustments and improvements in terms of operating conditions.

4.Maintenance Management Information System (MMIS) To ensure high-quality EfW plant maintenance and repair as well as enhance system and equipment reliability, CTCI has developed the Maintenance Management Information System (MMIS) based on the collection of historical repair and maintenance data over the years. Essentially, MMIS has an integrated function that includes spare parts procurement, warehouse management, as well as operational safety and health management. With MMIS, EfW plant managers can do many things, including: more effectively manage and control the progress of operations; run statistical analyses on equipment maintenance costs and assess whether an expenditure is reasonable; revise maintenance plans according to system equipment case history; and remind staff of the risks they should pay attention to during maintenance, so as to ensure stable operation of equipment and system as well as avoid unplanned shutdowns, thereby enhancing operational efficiency.

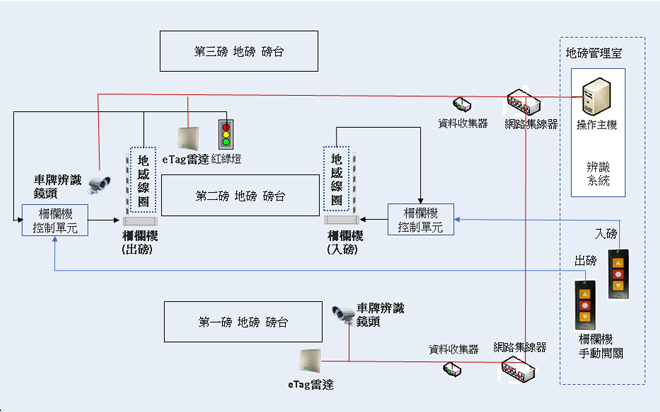

5.License plate recognition and electronic weighbridge system Miaoli EfW Plant is keenly aware of the advances of the latest technologies in the industry. In 2018, it was the first plant to apply smart vehicle entry recognition system to weighbridge management of collection vehicles going in and out of the plants. The system, which comes with long-range sensors and short-range license plate recognition, can proactively retrieve vehicle data for confirmation. Staff no longer need to worry about lost or damaged hand-held weight cards. This sheds the burden of vehicle management and helps speed up the vehicle weighing process.

CTCI is an experienced and skillful EPC contractor that overcame land issues and wind disasters before bringing Miaoli EfW Plant to fruition. Now in its thirteenth year of operation, Miaoli EfW Plant has not only adequately treated waste across the county, but has also done a good job in ecological and wetland conservation around the plant. Having received multiple recognitions from the EPA for exceptional performance, the plant continues to introduce new technologies and skills to enhance operating conditions, lower pollution, save energy, and cut carbon consumption. We therefore commend ECOVE Miaoli Energy Corp.’s overall service in waste treatment, which sufficiently meets the needs of Miaoli County Government. --Hua-Sheng Chen, Director of Environmental Protection Agency, Miaoli County Government