Technology

技術分享

ECOVE Introduces Intelligent Applications to Enhance Resource Cycling Efficiency

— Jui-Tung Hsu, Technical Manager, ECOVE Environment Services Corporation & Ping-Yao Yeh & Qi-Hong Hu, Engineers, ECOVE Environment Services Corporation, Group Resource Cycling Business

ECOVE, a CTCI company, has been actively introducing intelligent applications to its three main businesses of “waste management & energy-from-waste,” “renewable energy,” and “recycling & reuse.” Following the global trend of intelligent business management, we have built an integrated intelligent management system to allow managers to make timely judgment and response, and ensure stable operation of each project to improve operational efficiency. Using the example of incineration plants management, this article talks about how ECOVE effectively implemented circular economy through constant introduction of intelligent management models, thus fulfilling the vision of “being the most reliable provider of industry-leading ‘resource cycling’ services.”

Intelligent Incineration Plants Management

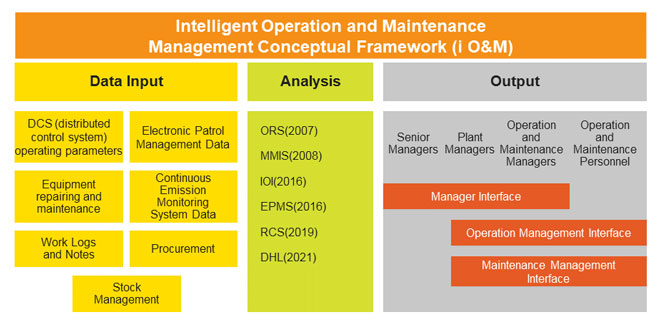

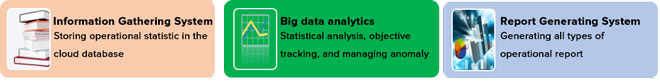

With rapid social and economic development and the improvement of people's living standards, how to tackle the challenge of decreasing natural resources and mounting waste have become an important issue for all residents in the global village. As the incineration processing technology advances, not only can we decompose harmful substances and reduce the volume of waste but we can also turn waste into energy (energy-from-waste; EfW) through furnaces, boilers, and generator modules, achieving the dual benefits of waste treatment and power generation. Now that the 24 incineration plants in Taiwan have seen a decline in operational efficiency due to the changing nature of waste, the aging of equipment, etc., intelligent management has proved itself an effective measure for maintaining or enhancing operational efficiency, apart from methods like upgrading processing equipment or improving operational technology. With more than 20 years of experience in waste management and incineration, ECOVE has accumulated abundant experience in plant operation & maintenance and a rich data library, and we are the first company in Taiwan to introduce the concept of intelligent management. We have established the Operation Results Management System (ORS) and Maintenance Management Information System (MMIS) in the early stage of incineration plants operation & maintenance (O&M) management, a starting point of our intelligent management. To meet new challenges from plant O&M, we have developed the Important Operations Information System (IOI) and Electronic Patrol Management System (EPMS), while also building the intelligent operation and maintenance management conceptual framework (i O&M). Based on this conceptual framework, we continued to develop the Remote Consulting System (RCS) and Digital Handover Log (DHL) for achieving the goal of intelligent and efficient management. The functions of each system are introduced below:

i O&M Management Conceptual Framework

1. Operation Results Management System, ORS

To effectively manage and control the operational status of each plant, ECOVE isolated important operating parameters and indicators that are closely related to operational efficiency of incinerators as the foundation for building the ORS based on rich operation experiences. After inputting the daily operational statistics, the ORS can perform an automatic statistical analysis, comparing current statistics to conditions set in the system such as management value, design value, and historical data, and send a reminder for any anomaly detected. Thus, managers can immediately keep track of the operation status of each plant and the field staff can use the data as basis to adjust and improve operation conditions.

ORS Operation Results Management System

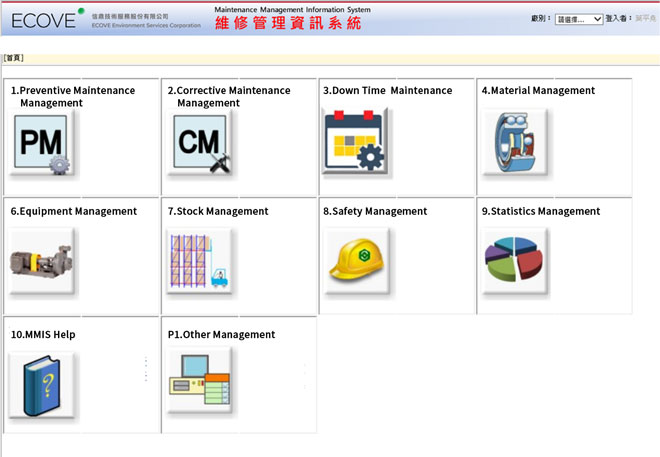

2. Maintenance Management Information System, MMIS

To enhance maintenance and repair quality of each furnace, increase operations reliability of system and equipment, and lower the risk of unscheduled shutdowns, ECOVE developed the maintenance management information system (MMIS). Utilizing historical repair and maintenance data over the years, MMIS combines the functions of spare parts purchasing, warehouse management, and operational safety and health management. With MMIS, we can effectively manage and control the progress of operational execution, conduct statistical analysis on equipment maintenance costs and its sensibility, revise maintenance plans according to system equipment case history, and remind operational personnel of the risks they should pay attention to during plant maintenance. Through MMIS, all plants are now able to maintain stable equipment systems operations, with enhanced operational efficiency.

Maintenance Management Information System

3. Important Operations Information, IOI

To help the management keep track of the operational statistics in real-time, ECOVE developed the IOI system which realizes remote inspection and supervision through mobile devices. When there is an anomaly detected in the plant operational information, the IOI will automatically send a text message to the manager to view the corresponding operational information then quickly give instructions for countermeasures and check the improvement results. Through the application of IOI systems, we transform mobile devices into mobile offices, achieving the goal of remote and real-time management.

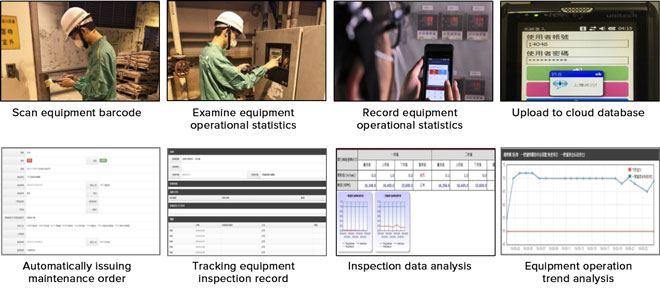

4. Electronic Patrol Management System, EPMS

Waste incineration is a continuous, uninterrupted process that goes 24 hours a day. To ensure that the plant equipment can maintain stable long-term operations, we need to conduct routine inspections to check equipment operational status, which is the most effective preventive measure. ECOVE’s in-house EPMS that goes with mobile devices to enable our personnel to conduct on-site inspections with ease and improve inspection efficiency. The EPMS also records equipment operational trends in detail and creates inspection data history. Moreover, by combining EPMS with MMIS, supervisor are able to keep track of the operational status of all key equipment of the plant and enhance management functions.

EPMS Electronic Patrol Management System

5. Remote Consulting System, RCS

By connecting with the screens of operating computers in the central control room of each plant, the management personnel can remotely supervise the operational process settings, parametric curves, and equipment operational status of each plant's distributed control systems (DCS) through mobile devices. These enable our management personnel to analyze the causes of anomalies and variations in operation trends, and track the operational status of each plant in real-time.

6. Digital Handover Log, DHL

A handover log is a tool for operational personnel to record work details of each shift, conduct work analysis and objectives management. When using traditional paper logs, operational personnel will be faced with issues such as time-consuming paperwork, inconsistent record quality, and difficulties in examinations. In order to overcome the aforementioned problems and improve the efficiency of handover logs, ECOVE has integrated the existing handover logs of each incineration plant and conducted user interviews then established a digital handover log (DHL) system that is easy to read and convenient to use and manage. Through digitalization and systematization of paper logs and the MMIS that allows users to view repair orders online, our on-site operational personnel can view work information like in-plant announcements, equipment operational data, to-do lists, and occupational safety controls during handover much more quickly and effectively.

Introducing intelligent management to increase operation performance

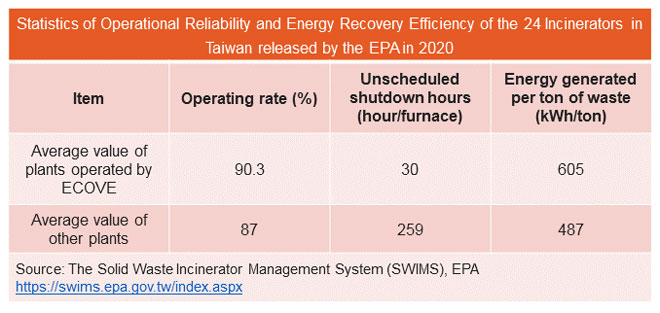

Through introducing intelligent management, ECOVE has effectively enhanced operational efficiency and service quality, achieving remarkable results in the operational management of incineration plants. In terms of key indicators including operational availability, process efficiency, and energy recovery rate, the large-scale municipal waste incineration plants operated and managed by ECOVE significantly outperforms other plants in all categories. According to the statistics on operating results of municipal solid waste incinerators by the Environmental Protection Administration (EPA) in Taiwan in 2020, ECOVE demonstrates impressive performances regarding the operating efficiency indicators of waste incineration plants, such as operation rate, unscheduled shutdown hours, and energy generated per unit of waste. ECOVE plants are 3.3% higher in operation rates in comparison to other plants operated by competitors, the unscheduled shutdown hours are 229 hour/furnace less than other plants, and energy generated per ton of waste is 24% higher than other plants.

Conclusion

ECOVE establishes the i O&M management conceptual framework by combining big data with abundant experiences in operating and managing incineration plants. With real-time decision-making and integration of management information in administration, operation, and maintenance, etc., it enables manager to make judgments and take actions for optimal solution in various situations, effectively improving the quality of operation and maintenance management and the operational stability of incineration plants. In addition, by applying this successful experience in intelligent O&M of incineration plants to other fields of recycling and reuse and renewable energy, we implement circular economy through real actions to realize the idea of "Every Resource Counts." Looking towards the future, ECOVE will continue to enhance the operational performance of incineration plants through technological improvement and development of intelligent management systems, further increasing recycling efficiency of every bit of resource. We will also introduce our successful experience in circular economy practices abroad, hoping to become a role model in circular economy practices globally.