Discover Reliable

發現信賴

CTCI Successfully Transformed Tunghsiao Power Plant into Taiwan’s Most Efficient Combined Cycle Power Plant

— Michael Li, Tunghsiao Power Plant Renewal Project Commissioning Manager, Technology Development Dept, CTCI Corporation, Group Engineering Business — Wen-Huang Yang, Assistant Chief Engineer, Construction Operation Dept, CTCI Corporation, Group Engineering Business

- Market:Power

- Owner:Taiwan Power Company

- Executive team:CTCI/Mitsubishi Power/Mitsubishi Corporation

- Commercial operation date:Unit 1 / February 2018; Unit 2 / May 2019; Unit 3 / May 2020

- Project location:Tunghsiao Township, Miaoli County, Taiwan

- Project Scope:engineering, procurement, construction, commissioning

- Capacity:2,678MW

Built in 1965, the equipment of Tunghsiao Power Plant has fallen short of current power demand and is not economical in terms of power generation efficiency. Taipower, the state utility owner, thus decided to renew and expand the plant to meet Taiwan’s power demand and support the government’s natural gas power generation policy. The new plant has three units under a 2-2-1 configuration, which contains two gas turbines, two heat recovery boilers, and one steam turbine. The project also includes balance of plant, such as condensers, electrical system, instrumentation and control system, demineralization water plant, wastewater treatment plant, seawater electrolysis chlorination plant, emergency generators, compressed air system, maintenance cranes, equipment foundations, and building construction work. On September 3, 2013, the consortium formed by CTCI, Mitsubishi Power and Mitsubishi Corporation was awarded the engineering, procurement, construction, and commissioning (EPCC) project contract. New units no.1, 2, and 3 have been put into commercial operation on February 27, 2018, May 30, 2019, and May 26, 2020 as scheduled, respectively. Adopting Mitsubishi Power’s latest gas turbine M501J, Tunghsiao Power Plant’s power generation efficiency is now enhanced to 60.7% from 42%, and is currently the most efficient combined-cycle power plant in Taiwan. Additionally, the NOx emission is now reduced to 5 ppm, which is far lower than the environmental law standard of 40 ppm and the 8 ppm commitment made during the Environmental Impact Assessment— a great contribution to Taiwan's environmental protection and CO2 reduction.

Why CTCI?

Experienced and Capable Power Plant EPC Contractor

CTCI is a global EPC contractor with experienced engineering and construction teams, a comprehensive engineering management system, and long-term supply chain partners. The company has undertaken many major power plant projects in Taiwan, such as Taipower’s Dahtarn, Linkou, and Talin power plants, as well as privately-owned power plant such as Kuokuang Power Plant. CTCI’s technological expertise and excellent services are the keys for winning the clients’ affirmation and trust.

Panorama of Tunghsiao Power Plant.

Plant layout drawing of Tunghsiao Power Plant.

Reliable Realized

Thorough Communication to Integrate Construction Schedule and Interface

A renewal project such as this one means that existing generating units remain in operation when the work is going on. Adding to this challenge is that Taipower has a number of ongoing projects related to this project, such as natural gas transmission system, seawater pipeline, pump house, and outfall pit. Therefore, during construction and commissioning phases, the progress of all relevant systems must be monitored at all times to ensure that natural gas, cooling water, and power could be supplied in time. In order to complete the project smoothly, the project team made sure the schedule is strictly controlled. The team actively convened various coordination meetings with Taipower and other contractors to streamline the traffic flow of construction equipment, and confirm the work areas for each contractor. Through adequate communication and integration, the project was completed on schedule.

Project Highlight

Supplying Power in the Shortest Time Possible to Prevent Power Shortage

Back in 2017, when the project was still ongoing, Taiwan’s electrical system reserve was challenged with insufficient power supply for summer peak demand. According to the original schedule, following the seawater admission of unit 1 on August 1, 2017, it would take 5.5 more months to reach official dispatch date (ODD). This arrangement, however, was too late to support the power demand for the summer. In order to avoid the power curtailment crisis, the project team fully cooperated with Taipower’s request and mobilized all manpower and resources to shorten the test run period. With their diligent work, power synchronization succeeded on August 21, and with one gas turbine and one steam turbine, unit 1 was able to generate power on September 5. Commercial operation was achieved in February 2018, half a month ahead of schedule. To complete the task on time, the project team must overcome the following challenges: 1.Add temporary cooling equipment: According to the original plan, the required tests for gas turbine ignition were scheduled after seawater admission. It would have taken 30 days to go through all 34 test items. In order to shorten this period, the project team took an alternative plan to get most of the test tasks done before seawater admission. In the end, the team successfully reached GT ignition condition just one day after seawater admission. 2.Integrate the test run items: The test items were comprehensively reviewed, and some test items were changed or merged to shorten the time required, which greatly reduces the time required for test runs. 3.Integrate the test run items: The test items were comprehensively reviewed, and some test items were changed or merged to shorten the time required.

Smarter Engineering

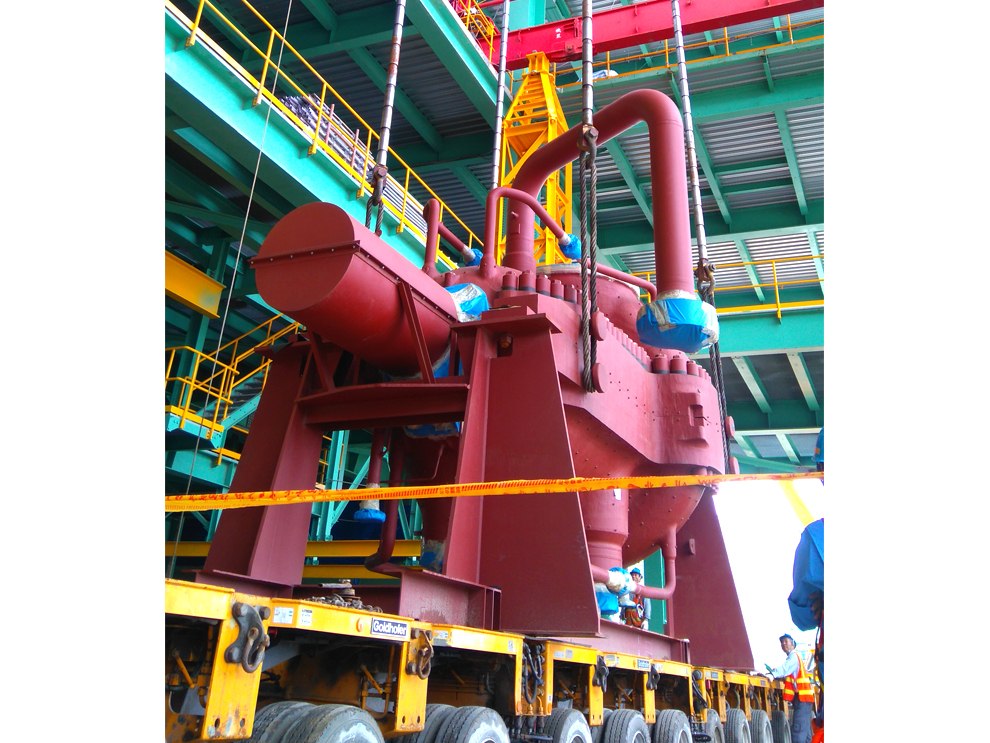

I. Heavy Material Lifting and On-Base Operations

With 60 HRSG (heat recovery steam generator) modules— each 29 meters long and 264 tons in weight— to be lifted and installed in a confined space, it poses an extreme challenge. To cope with this challenge, the construction team studied thoroughly the related works’ schedules in the early stage in order to get enough working space.

Besides, equipment with overweight loads, such as gas turbines, steam turbines, and associated generators— each weighing 287 to 321 tons— must be moved into the building, lifted and secured on-base. Due to space limitations, special equipment were used for this operation to overcome field restrictions and ensure safety and effectiveness.

II. Resource Cycling for Sustainable, Green Life

This project scored Outstanding Performance in Taipower’s 2018 Green Environmental Protection Evaluation, a program that selects “green project sites” in line with the Environmental Protection Administration’s policy according to air pollution law amendments. Evaluation criteria includes environmental protection systems, management measures, effectiveness, and innovation. The project site actively implements sanitation measures and environmental protection management at all levels. Measures include: Provide RO drinking water and steel lunch boxes for employees; provide health care services; reduce use of plastics and waste. To save water, the project team used water from sedimentation pond and storm water detention basin for sprinkling road, landscaping, and toilet cleaning purposes, saving up to 310,000 tons of water per year. A shelter above the basin was also set up to create a cool and relaxing rest place for workers in midsummer. All of these help create a friendly working environment centered around the concept of resource cycling.

After seawater admission on August 1, 2017, the GT1-1 was successfully fired on the next day on August 2, 2017. Taipower CPCO/TungHsiao Power Plant/CTCI/Mitsubishi team posed for a group photo in the control room.

From engineering, procurement, construction, testing, to power synchronization, CTCI team overcame challenges and reached every important project milestone, demonstrating supreme professionalism and team morale. Looking back, in order for Unit 1 to supply power in time, as soon as all safety tests were performed, CTCI team immediately set out to carry out power generation tests during daytime and conducted other uncompleted operation tests in the evening or holiday off-peaks. Two-to-one synchronization was completed well ahead of schedule in 2017, supplying power to meet the power demand in the summer peak of that year. During the period, the team worked around the clock to accomplish the task. Their hard work was self-evident. I sincerely appreciate CTCI team for their devotion. It's nice to have you! --Wang Chun-Shan, Deputy Director at Central Construction Office, Nuclear Power Division, Taiwan Power Company