Outlook

趨勢與展望

Triple Arrow Shots to Advance into the Era of Circular Economy

Group Resource Cycling Business CEO J.J. Liao

Under the trend of the circular economy, all industries in the world are facing the demand of transformation to reduce waste and pollution caused by the linear economy. Adhering to the philosophy of “Every Resource Counts,” CTCI’ s ECOVE Environment Corporation (ECOVE), which specializes in resource cycling business, has a firm grasp of the general trends of circular economy and developed a circular strategy under years of deep cultivation and innovative application. ECOVE uses its three main businesses: Energy-from-Waste (EfW) and waste management, recycling, and photovoltaic power, to link the three major cycling modes so as to create the economic value of resource cycling, to maximize resource cycling efficiency, and achieve a win-win situation for both economy and environment.

Triple Three Strategies to Improve Resource Cycling Efficiency

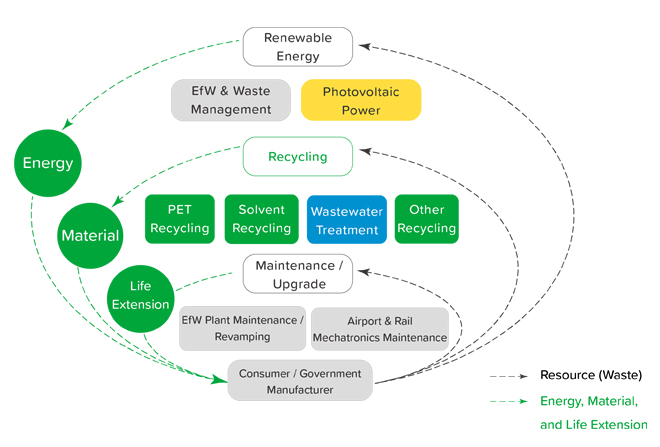

Taiwan's resource recovery rate and recycling technology ranks among the best in the world, and its globally unique waste recycling technology has been hailed by the Wall Street Journal as "The World's Geniuses of Garbage Disposal." As the largest environmental resource management service company in Taiwan, ECOVE has a unique approach to how to improve the efficiency of resource cycling. The figure below illustrates how ECOVE achieves the three major objectives of resource cycling by using the three cycling modes to link the existing three businesses through the continuous innovative research and development. The operation of the triple three cycling is: 1. Maintenance/Revamping Through maintenance and renovation, the service life of the old equipment is extended, and the resource consumption and environmental pollution are reduced. This is also the most basic cycle. 2. Recycling Using innovative technology and techniques to bring new life to waste that was previously considered useless and bound for final disposal, making it a usable resource and achieving a cycle of material reuse. 3. Renewable Energy The waste that cannot be reused is sent to the EfW plant for combustion to generate electricity, and is converted into renewable energy for reuse to achieve a cycle of energy. Although photovoltaic power is not the main source of electricity today, the industry has unlimited room for growth.

ECOVE Resource Cycling Development Diagram

ECOVE hopes to gradually achieve the goal of zero waste through these three cycles, and has obtained the world’s first BS8001 Circular Economy Audit Statement in May 2017, which has affirmed its innovative models and achievements through years of efforts in “enhancing resource cycling efficiency”.

Maintenance/Revamping--First Line of Defense to Implement the Circular Economy

Maintenance and revamping, while seemingly simple, are the most fundamental parts of putting the circular economy into practice. For the discarded waste to be first returned to its raw material form and then processed into a product for a return to the market, it needs to go through complicated processes including collection, disassembly, refining, manufacturing, and assembly, which will consume a lot of energy. By extending its life cycle, however, the reduced energy consumption is directly and significantly effective. ECOVE has more than 20 years of experience in EfW and waste management, and its business areas cover Macau and China. This year, ECOVE successfully completed the revamping of the equipment in the Gangshan EfW Plant based on its rich experience in EfW plant management, maintenance, and proprietary technology. In just 4 months after taking over, the main obstacles were eliminated, and the operation rate was increased from 73% in the same period to95% , which greatly improved the operational efficiency. The difficulty of this project is quite high, and its successful experience may be useful in the future as a reference for other EfW plants that are due to retire but choose to revamp to extend the service life. This also extends the service depth and breadth of ECOVE in the field of EfW plants. Through the accumulated technical skills and experience in the maintenance of EfW plants, ECOVE has successfully extended its service scope to mechanical and electrical maintenance services for airports, rail stations, and so on. At present, there are more than 10 projects that ECOVE is working on. ECOVE will continue to deepen its strength and expand its client base in the future.

Recycling - Creating Resource Recycling Value

Although Taiwan has a high resource recovery rate, its Cyclical Use Rate (CUR) in 2017 is only 15.92%, which shows that there is still a long way to go in the promotion and technological development of the recycling in the resource cycle. In the past, most of the domestic waste was only recovered at the front end and then sent to the EfW plant for energy conversion, which wastes many valuable resources. To develop this field, ECOVE actively seeks technology and strengthens the integration and application of process to expand resource cycling efficiency and develop a circular economy. The results at this stage are aimed at the treatment of waste and sewage generated from product manufacturing and consumption. ECOVE's PET bottle recycling plant in China has been able to convert the PET flakes into polyester staple fibers (PSF) and partially oriented yarn (POY) for remanufacturing textile. For water treatment, ECOVE is also invested in reclaimed water plants in addition to the operation of a number of the gravel purification treatment stations and sewage treatment plants. The first reclaimed water plant in Fengshan River has recently been completed. The sewage after secondary treatment in the plant can be supplied as industrial water. It is expected to provide 25,000 metric tons of reclaimed water per day to the local industrial parks. In addition, there are still many studies underway on the technologies to convert waste to material. Among them, for the waste isopropyl alcohol (IPA), there is already a technology that can concentrate low-concentration waste IPA till 99.5% as industrial grade products. It is estimated that about 6,700 tons of waste solvent can be recovered each year in the future. After processing and refining into industrial raw materials, these products can be returned to the market supply chain. This is the recycling model developed in-house and from scratch by ECOVE, and an important deployment in the circular economy. This model will also be replicated in the future to expand to other fields and overseas markets.

Renewable Energy - Expanded Investment to Develop Photovoltaic Power

ECOVE is optimistic about the development potential of renewable energy, and its business landscape has been successfully expanded from incineration power generation to photovoltaic generation. In the case of incineration power generation, the EfW plants operated and run by ECOVE in Taiwan can supply electricity to 260,000 households a year, while the Macau EfW Plants can supply electricity to 30,000 households every year. In addition, ECOVE this year has secured the Taoyuan Biomass Energy Center BOT project, which is the first domestic comprehensive waste treatment plant in Taiwan in the past 20 years that has introduced international advanced technology. The designed power generation efficiency of this landmark biomass center is more than 25%. It can recover the waste heat generated during the heat treatment process. In addition, through anaerobic digestion technology, it can also produce biogas from the kitchen waste which is with high moisture content and not suitable for burning to generate electricity. This allows the kitchen waste to produce a higher value. To enhance the operational efficiency of the various EfW plants, ECOVE monitors the records of all plant operations, and analyzes more than 2 billion data daily. These information forms the basis for ECOVE to make the best operational decisions and improvements. This technology is also applied to Macau, including two EfW plants and a special waste treatment plant, increasing the power generation per ton of waste from 250 kWh to 300 kWh. According to the green energy policy of Bureau of Energy, Ministry of Economic Affairs, Taiwan's installed capacity of photovoltaic is expected to reach 20 GW by 2025, and the annual generation capacity will reach 25 billion kWh, making Taiwan a sizable market in solar power globally. GDDC, which was established to enter this field, has its services covering the main areas of upstream and downstream of the solar photovoltaic industry and related investment development. Under the active expansion, GDDC has successively interconnected 43 photovoltaic power stations, including roof type, ground type, and floating type, with an interconnected capacity of 40 MWp, which is sufficient to supply electricity to about 15,000 households a year in Taiwan. In addition, GDDC has successfully entered the US market and completed the grid interconnection of the Lumberton Photovoltaic Power Plant in New Jersey in 2016. In addition to continuing to develop related business in Taiwan and the U.S. in the future, ECOVE will focus on other major markets around the world as well and look for suitable investment targets to expand its operations.

Every Resource Counts

There is a saying: "The bigger your goal, the bigger your power." ECOVE aims to There is a saying: "The bigger your goal, the bigger your power." ECOVE aims to become "The most reliable provider of industry-leading resource cycling services" to provide professional service to assist industries to improve resource cycling efficiency. It is believed that with the expansion of ECOVE's three main businesses, the resource will move toward a better cycle.