Sustainable Future

永續未來

CTCI Advanced Systems Inc. (CTCI ASI) - The Accelerator of Innovation in Sustainable Industries

In 2015, 193 members of the United Nations adopted the 17 Sustainable Development Goals (SDGs) of the 2030 Agenda for Sustainable Development. CTCI ASI commits itself to developing and implementing various green technologies. It is also committed to providing economical, feasible environmental protection/energy-saving solutions to its customers for a long time, which perfectly echoes the 9th goal:“Build resilient infrastructure, promote sustainable industrialization and foster innovation. With its professionalism and innovative technologies, CTCI ASI has been practicing Corporate Social Responsibility (CSR) continually since the first release of its CSR report in 2009. CTCI ASI aims to be the accelerator of innovation in sustainable industries to help its customers achieve their goals of intelligent transformation and sustainable management, and to promote national economic development. In 2017, CTCI ASI won the Taiwan Corporate Sustainability Award (TCSA) in “TOP 50 Corporate Sustainability Report Award in Service Industry Gold Award”, a recognition of CTCI ASI’s efforts in practicing corporate social responsibility.

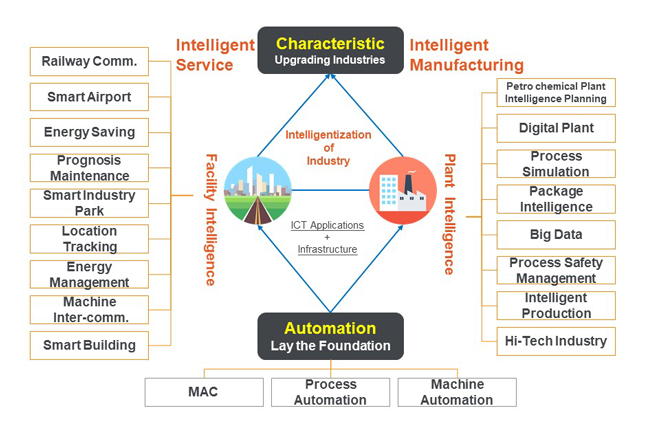

Intelligent Technology and Industry Upgrading

The industrial age has undergone changes in the areas of power generation and automation. Today, it is moving toward “intelligence”, and the fourth industrial revolution (Industry 4.0), which combines the Internet of Things (IoT), Big Data, Cyber Physical System, and Cyber Physical Production System. The core purpose of Industry 4.0 is to improve the competitiveness of industry and reduce the impact on the environment. CTCI ASI has noticed this trend before Industry 4.0 swept the industry. Based on the original concept of industrial automation control, CTCI ASI has actively developed new solutions for Industry 4.0 by using new information technologies such as IoT, cloud computing, and big data analysis. Using its experience in turnkey projects, CTCI ASI now provides intelligent solutions to plants and creates new industrial manufacturing models that can help its clients achieve their environmental and corporate sustainability goals. With its innovative Industry 4.0 strategy and the use of big data analysis, CTCI ASI has led the development of more than 30 sets of cross-industry intelligent platforms, products, solutions, and patents for production optimization, energy saving, and safety warning. By providing services for intelligent plants, intelligent transportation, and intelligent buildings, CTCI ASI helps to improve the quality of life and build an eco-friendly society. By using intelligent technologies, CTCI ASI provides guidance and assistance in automation and upgrades for petrochemical, electronics, mass rail transit, and aviation industries, helping them to improve service quality, production optimization, energy efficiency and safety, as well as enhance competitiveness. To date, CTCI ASI has assisted approximately 20 plants to increase output value and yield, guided more than 30 companies to obtain ISO51001 certification, provided energy saving services to energy-consuming manufacturers including 12 global wafer fabrication, established over 80 sets of factory safety platforms and more than 400 sets of early warning systems for more than 90% of all medium and large petrochemical plants in Taiwan, and security systems to international airports. The following explains the implementation of CTCI ASI’s two core values of I) energy conservation and carbon emission reduction, and II) industrial safety and risk (early warning) management enhancement.

ASI Smart Service / Manufacturing Development Strategy

I.Energy Conservation and Carbon Emission Reduction

Product diversification is underway in many industries. As a result, expectations of the production environment are more demanding than previously. For example, in order to maintain the environmental factors (including temperature and humidity) required by products and production equipment, the air-conditioning systems in plants consume a lot of energy. Energy conservation and carbon emission reduction are critical issues in modern society. By using energy KPIs and integrating energy and resources, plants can save energy and reduce emissions. New mathematical modeling analysis and system management can help make this possible. 1.Energy Baseline Management (Mr. Energy) CTCI ASI’s Power Monitor system monitors in real time all power information for each monitoring point and integrates power monitoring systems with energy management systems. In addition to helping customers meet ISO 50001 system certification requirements, Power Monitor can generate performance indicators such as energy consumption per unit product. By creating different Energy Performance Indicators (EnPI) such as by plants, production lines, utility systems, and comparing the real-time data with baselines, industrial enterprises can systematically implement and improve energy management. 2.Guiding Process Simulator (GPS) for Distillation System The distillation system is one of the most important assets in a plant. It also uses the most energy. The GPS uses the process simulation platform to establish steady state and dynamic process modeling of a distillation system. That is, via the disturbance of the process to simulation, predict and diagnose the safety and stability of operational procedures. Then, via the safety factors, including control and system parameters, we define safer and more efficient operational strategies so as to help plants operate their distillation system at new and higher levels of safety and efficiency. Furthermore, operators will be also able to attain energy conservation and carbon emission reduction. 3.Intelligent Air-conditioning Energy-saving Monitoring System (FMACS) Electricity is one of the most consumed energy forms in most buildings. The main electricity-consuming items are air-conditioned cold rooms, hot rooms, and illumination system depending on climatic fluctuation. FMACS can represent the condition of every component in an air-conditioning system via psychometric chart, import the optimal algorithm to calculate energy requirements, analyze air distribution pathways, and control the energy consumption of air-conditioning equipment so as to conserve energy. Moreover, the effectiveness of PID control can be enhanced by implementing a non-linear control system for the air-conditioning system. 4.A Solution to Energy Conservation : Frequency Conversion of Cooling Tower Fans CTCI ASI has collaborated with a customer to save 1% of energy in its plants that consume 800kW per year. In order to achieve the goal, CTCI ASI installed frequency convertors on the cooling tower fans and implemented a control mechanism that links the cooling tower temperature with the electric plate. Changing the temperature of the cooling tower automatically adjusts the rotation speed of the fans, thus reducing electricity usage. Additionally, the automatic frequency conversion further reduces energy consumption and alerts maintenance staff to equipment failures, making rectification faster. After the installation, an average 21.4% energy conservation was achieved, surpassing the original target of 15%. As a result, the customer saves up to NTD 170,000 (almost USD 5,825) per year in electricity costs. 5.Dynamic Simulation Analysis for Flare Gas Recovery System Design and Controllability Using the ASPEN Plus Dynamics solution, we are able to verify the programming design of Flare Gas Recovery System (FGRS), controlling strategy and the analysis of feasible operations. Operating conditions are then set that enable energy conservation and FGRS system stability such that the recovery system can produce the best results no matter the circumstances, thus providing safe production and the recycling of reusable resources. Last but not least, compared to a steady state system, a dynamic state system can be much more capable of representing the reaction state of the changes in systems. 6.Lighting Energy ESCO Case With the help of the ESCO subsidy from the Bureau of Energy, CTCI ASI has helped customers to replace the high energy-consuming lights in a school and improved its energy consumption efficiency. After the improvement, the energy saving rate of the whole school is 57.4%, allowing it to save about NT$ 970,000 in electricity cost and reduce CO₂ emissions by 159.8 tons per year.

II.Industrial Safety and Risk Management Enhancement

The Ministry of Labor, Taiwan (R.O.C.) announced the regulation of process safety and regular assessment enforcement in January 2015. Enterprises are required to assess process safety every 5 years, document processes and evaluation results in a process safety report, and take preventive measures. CTCI ASI has developed Process Safety Management (PSM), which contains 14 items to audit processes and deliver the required form of audit report and assess the effectiveness of the items that are required to be audited. This is one of the most frequently used solutions to reduce process risk, especially for high-risk processes in the petrochemical industry. PSM helps to ensure safety during chemical process design, minimize the consequence of human error, and help customers perform audits correctly and efficiently. 1.Process Hazard Analysis (Mr. Safety-HazOp/LOPA) Industrial safety is one of the most important issues in the world. Both companies and governments strive always avoid serious industrial accidents that might lead to the loss of reputation and other factors. Mr. Safety is mainly applied to the petroleum and chemical industry. It can recognize and evaluate the risk of a process and structuralize and systemize the process and the operation. It improves process control by effective recognition and risk assessment, and diagnoses different situations to attain real prevention. 2.Factory P&ID intelligence Eco-consciousness is on the rise in Taiwan. Serious industrial safety breaches or environmental protection inaction or failures not only affect plant operation but places the staff concerned at risk of criminal responsibility. A complete P&ID database should contain three aspects: improving safety during operation in petrochemical plants, promoting the quality of maintenance, and lowering the risk of industrial issues or environmental protection problems. 3.Long-distance Pipeline Transportation Information Collection and Monitoring Platform After the underground pipeline gas explosion in August 2015 in Kaohsiung City, all parties concerned proposed that the relevant government agencies immediately set up a mechanism to monitor both sides of the pipeline to increase the transparency of pipeline transportation information. Since information on the underground pipelines had not been available for a long time, government agencies were tasked with leading the establishment of pipeline transportation information collection and monitoring platforms after agreements with local oil companies, including CPC. In the past, only the transfer terminal had master information on the storage of raw materials (receiving parties only had flow, pressure, and other data detected in the plant) and the onus was on on-duty personnel to determine whether the pipeline was operating normally or not. With the aid of the long-distance pipeline transportation information collection and monitoring platform, on-duty personnel can be more effective at detecting abnormalities in the pipeline. 4.Giving Consideration to both Safety and the Rational Management of the Alarm System Besides being the governmental policy, the operators of every plant would normally take control of the elements that might pose potential danger by regularly analyzing process hazards in every unit in the refining and petrochemical industry. “Giving consideration to both safety and the rational management of the alarm system” is a key concept based on process jeopardy analysis-HazOp/LOPA with ISA18.2 alarm management, which is composed of three dimensions: the accuracy of the instrument, the effectiveness of the alarms, and the SOP of how to cope with emergencies. The rational management of the alarms given by DCS enables the operators to know the vital warning in time and take following measures to handle the thorny scenarios.

Accelerating Innovation in Sustainable Industries

Focusing on its core business, CTCI ASI actively responds to climate change issues and greenhouse gas emission reduction. Aiming to be the accelerator of innovation in sustainable industries, CTCI ASI collaborates with its clients on energy conservation and environmental protection management. Using a variety of green technologies, CTCI ASI provides clients with economical and feasible solutions to protect the environment. In order to meet the requirements of global supply chains and enhance competitiveness, CTCI ASI will continue to strengthen its management structure, match its CSR programs and efforts with its corporate core values, innovative technologies and solutions, and continuously enhance its corporate core values. CTCI ASI will fulfill its social/civic responsibilities by implementing sustainable development and environmental conservation.