Technology

技術分享

A Look at CTCI Engineering

3D In-depth Application

There is a saying that “a picture is worth a thousand words.” While engineering design has traditionally relied on detailed 2D drawings, the growth of plant sizes and the complexity of modern plants has meant that information from 2D drawings are insufficient for engineering works and can no longer meet the demands of the owner. Thanks to advances in computer science, 3D models can now display more accurate information. “A 3D model is worth a thousand pictures” aptly describes the transition from 2D to 3D. The EPC lump-sum project is an engineering service with mass customization. CTCI has been innovating and researching 3D technologies over many years to deepen the application of 3D in the execution of EPC projects. We are now well positioned to implement this service concept in EPC working items such as engineering, procurement, construction, commissioning, and handover. For example, through innovations sourced internally and externally, we have developed 3D applications that integrate with overall plant planning; improved the project working processes to construct a digital plant; and developed a 3D global collaboration platform using new techniques. These capabilities contribute to improving CTCI’s competitiveness in the rapidly changing international engineering market.

3D Animation Simulation — Overall Plant Planning

In the overall plant planning stage, the drafting tools have evolved from pen and paper, 2D, and 2.5D to 3D design software. Software can provide not only an environment for digital engineering, but also the flexibility required by engineering companies for the execution of projects. But this type of software can only present the statistical status of the 3D model, and does not adequately meet the demands of the market. Thanks to industry-university cooperation between CTCI and NTU, planning can now be simulated with animation using 3D virtual image capture technology rather than written information. This assists our clients in understanding the status of overall plant planning, design, and construction more precisely during the execution of a project. For example, competition between international refinery and petrochemical plants has intensified. While individual owners try to expand capacity to gain market share, serious consideration must be given to the manufacturing of the equipment and installation when increasing capacity, considering that some key equipment such as towers can easily weigh over 1,000 tons. As such, transporting the equipment from a foreign location to the site needs to take into account various factors, such as insurance, weather conditions, road conditions, pier-carrying capacity, and lifting operations. To ensure the safety and reliability at each step, CTCI cooperates with the Civil Engineering Department at NTU to develop an advanced 3D animation system to present the rigging plan for the equipment. Using animation, the risks of lifting such equipment can be assessed and managed precisely by checking critical points according to the following factors: space requirement before lifting, the arrangement of the lifting route, as well as any interference from the surrounding facilities on the lifting procedure. By doing so, the placement of the equipment can be verified against the safety and construction schedule requirements for the lifting, which helps to avoid adjustments to the overall plant planning due to construction concerns.

Construct a Digital Plant

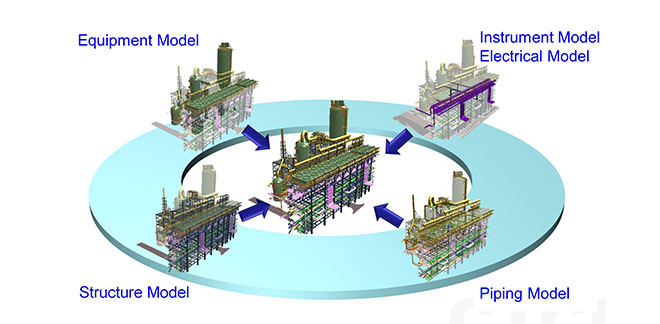

A 3D application in the EPC lump-sum project was used to review the design outcome and produce 2D drawings. With advances in computer technology and the development of network communications and databases, CTCI has ingrained 3D deeper into engineering information used for planning, design, procurement, construction, commissioning, and operation & maintenance. Database information is imported from various locations and shared with every project management level in order to achieve the goal of constructing a digital plant. In addition, CTCI combines the concept of BIM (Building Information Modeling) and digital plants by using laser scan techniques to input and digitize information from the existing plant so as to expand or revamp projects. This technology enhances the capability of space management. A 3D model is created by incorporating piping, structures, equipment, instruments, and electrical facilities for space management. Different departments carry out the interference check, measurements, and mark-ups, then share the information in a 3D environment. Moreover, non-physical space for operations and maintenance can be built into the 3D model in advance to avoid being occupied by other fixed facilities. CTCI uses 3D modeling as the basis for space management rather than reviewing 2D drawings to check the engineering design. All the working procedures are based on 3D modeling — design teams in different departments can discuss issues by checking the combined design information in the form of a 3D model.

Diagram 1: Digitizing Engineering Information

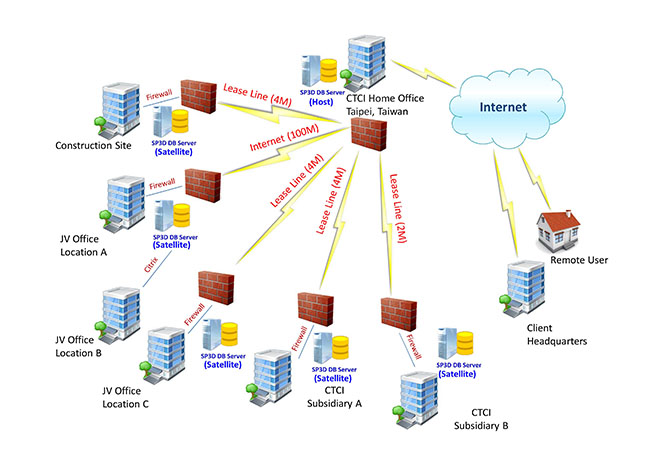

Integrated Information Synchronization — A complete global collaboration platform

From engineering companies to EPC lump-sum companies, in both domestic and international markets, the trend of EPC project execution is to make the most of resources from different global locations. The design team at CTCI’s headquarters in Taipei collaborates on an on-going basis with overseas joint-venture partners and subsidiaries. However, there are plenty of procurement items in the EPC lump-sum project; the procurement team has to inquire at the design stage in order to accelerate the procurement process and improve efficiency. As the scale of EPC lump-sum projects grow, the importance of schedules and safety controls of the construction teams becomes paramount. In light of business expansion, CTCI requires a platform that strings multiple connections together. Therefore, the design team is committed to the development of a collaboration platform as a means of it implementing a 3D global collaborative system. This allows a digital plant of a EPC lump-sum project to work simultaneously with our subsidiaries, joint venture partners, and sites globally through a private network or the Internet. The design, procurement, and construction teams all around the world can track the project’s progress by connecting to the platform anytime, anywhere, thereby substantially increasing CTCI’s competitiveness in the international market.

Diagram 2: Global EPC Project Collaboration Platform

Promoting Industry 4.0 with full strength

As the leading contractor in the domestic EPC lump-sum sector, CTCI has been at the forefront of innovating and researching engineering service solutions for over 30 years, while, at the same time, keeping an eye on the industry’s development needs. CTCI is well prepared for the forthcoming wave of Industry 4.0, given its accomplishments in the construction and integration of digitized information, which includes design, procurement, construction, commissioning, and operations.